Dust separation and collection device

A collection device and dust separation technology, which is applied in solid separation, separation of solids from solids by air flow, and plastic recycling. , Reduce the effect of secondary adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

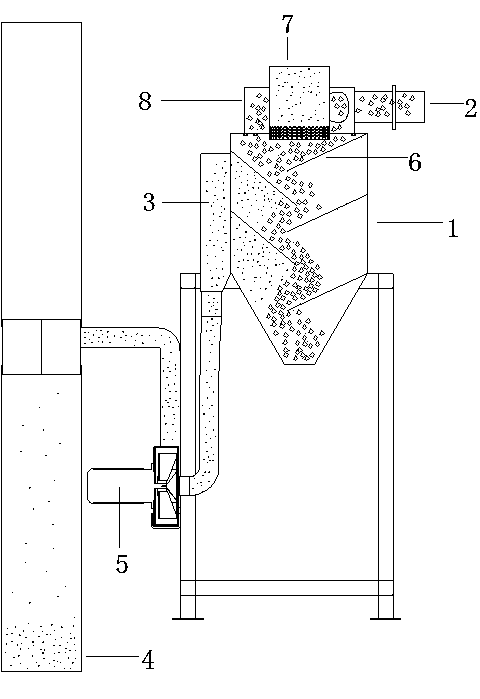

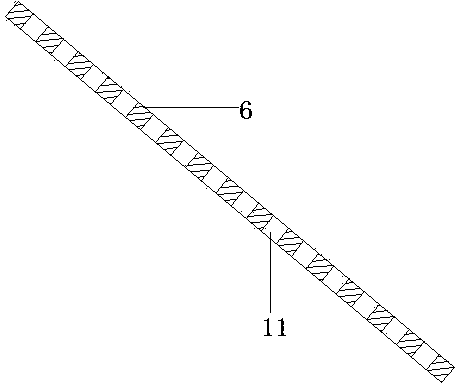

[0025] Embodiment 1: as figure 1 A frequency conversion separation device for plastic dust is shown, which includes a dust removal main cylinder 1 and a feed port 2. The dust removal main cylinder 1 is connected to a dust collection bag 4 through an air guide pipe 3, and the air guide pipe 3 is A wind-guiding and dust-absorbing fan 5 is provided, a plurality of material-guiding sloping plates 6 are arranged inside the dust removal main cylinder 1, and a discharge port is provided at the lower end of the dust removal main cylinder 1 . The main dust removal cylinder 1 is provided with a cyclone cylinder 7, and the side wall of the cyclone cylinder 7 is provided with a dust suction mesh. The direction is from bottom to top, the cyclone 7 is located at the upper end of the dust removal main cylinder 1, and the cyclone 7 is provided with a pre-dust removal tube 8, and the pre-dust removal tube 8 is connected to the feed port 2. The sloping material guide plates 6 are located on bo...

Embodiment 2

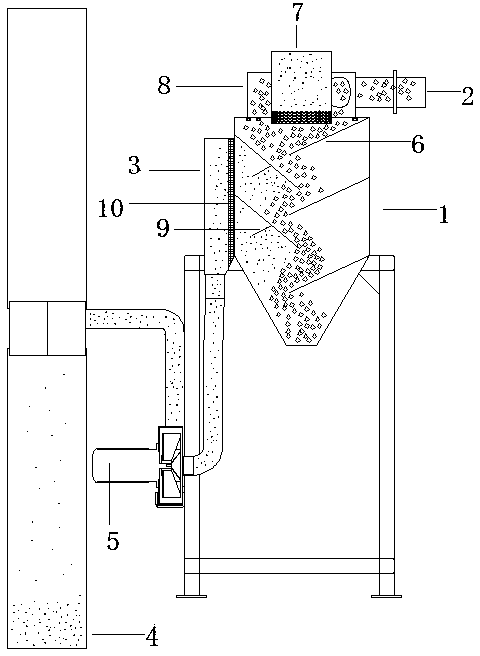

[0027] Embodiment 2: as figure 2 , image 3 The present embodiment shown, its structure and implementation mode are basically the same as embodiment 1, the difference is that a wind collecting plate 9 is provided on the material guide sloping plate 6 close to the air guide pipe 3 side, and the wind collecting plate 9 The end away from the air guide pipe 3 is connected to the lower surface of the sloping material guide plate 6, and an air gathering port is formed between the wind gathering plate 9 and the sloping material guide plate 6 below. The existence of the air-gathering port can accelerate the speed and strength of the suction airflow, and after the airflow accelerates, some plastic particles will deviate accordingly, hit the wind-gathering plate 9 and be rebounded downwards, which increases the number of collisions and ensures the adsorption. The dust is shaken away from the plastic particles to improve the separation effect. The lower end of the half cylinder part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com