Multilayer composite ceramic coating for hot dip galvanizing and preparation method thereof

A multi-layer composite and ceramic coating technology, which is applied in coatings, chemical instruments and methods, metal material coating technology, etc., can solve problems such as poor mechanical properties and thermal conductivity, poor liquid zinc corrosion resistance, and low material life , to achieve good thermal conductivity and thermal shock resistance, good resistance to liquid zinc corrosion, and high thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

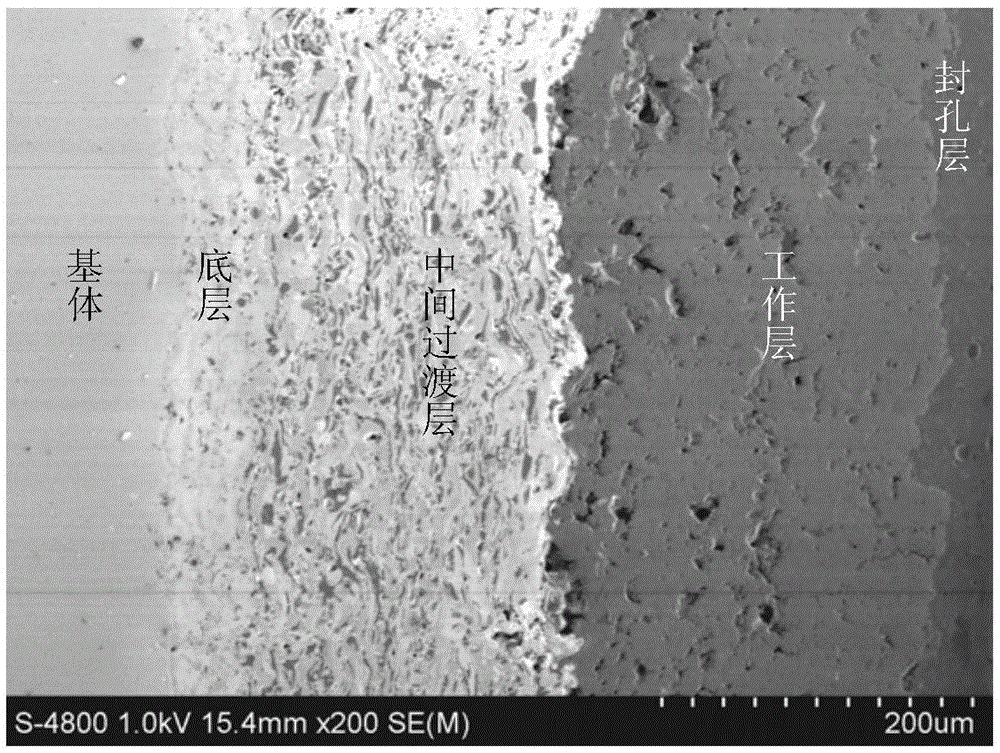

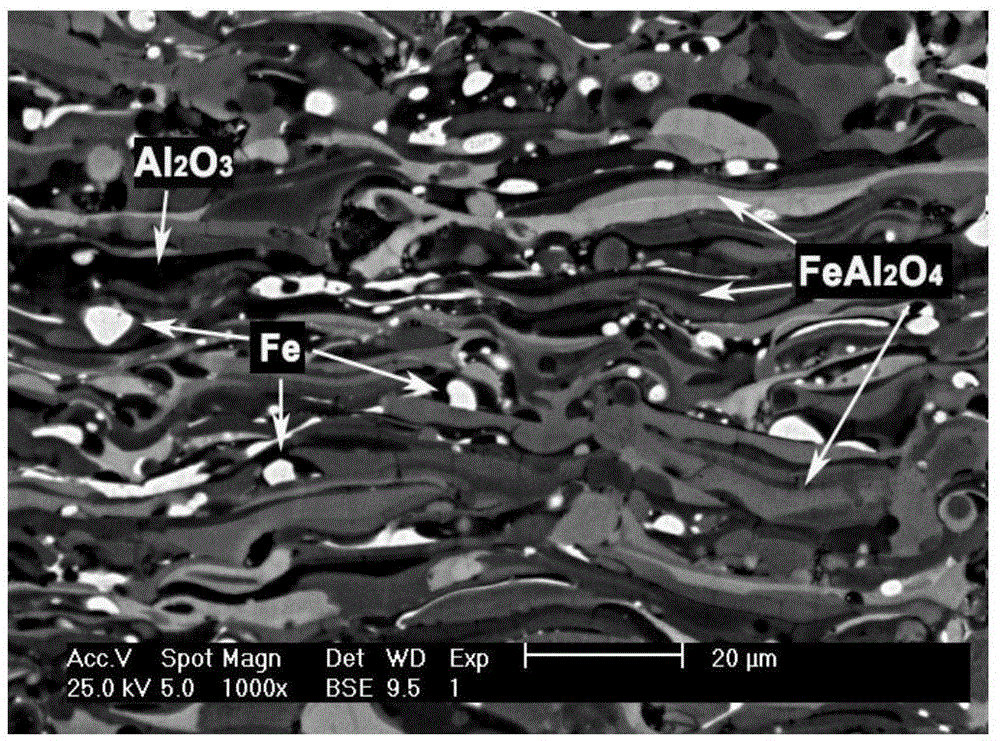

[0066] This embodiment is used for the multi-layer composite ceramic coating of hot-dip galvanizing. The base material is Q235 carbon steel, and the microcrystalline self-fluxing alloy layer of Fe-Al is used as the bottom layer. The thickness of the bottom layer is 100 μm, and Al- Fe 2 O 3 The ceramic-based nanocrystalline ceramic-metal composite layer n-(Fe 1-x Al x )(Fe x Al 2-x )O 4 -Fe-Al 2 O 3 It is an intermediate transition layer, the thickness of the intermediate transition layer is 400μm, and the ZrO sealed with ceramic glass 2 The oxide ceramic layer is the working layer, and the thickness of the working layer is 200μm, which constitutes a multilayer composite ceramic coating for hot-dip galvanizing, wherein the underlying alloy has a microcrystalline structure, and the ceramic-metal complex phase transition The layer is a nanocrystalline structure, and the ceramic glass sealing oxide ceramic working layer has a microcrystalline + amorphous structure. The multilayer com...

Embodiment 2

[0094] Except that Q195 plain carbon steel is used as the base material of the multilayer composite ceramic coating, everything else is the same as in Example 1.

[0095] Picture 9 This is the SEM photograph of the cross section of the multilayer composite ceramic coating for hot-dip galvanizing of this embodiment. It can be seen from the figure that the multilayer composite ceramic coating is composed of Fe-Al layer alloy bottom layer, complex phase iron aluminum spinel (Fe 1-x Al x )(Fe x Al 2-x )O 4 -Fe-Al 2 O 3 Intermediate transition layer, ZrO sealed by ceramic glass sealing layer 2 The ceramic working layer is composed of a good combination of sublayers inside the coating.

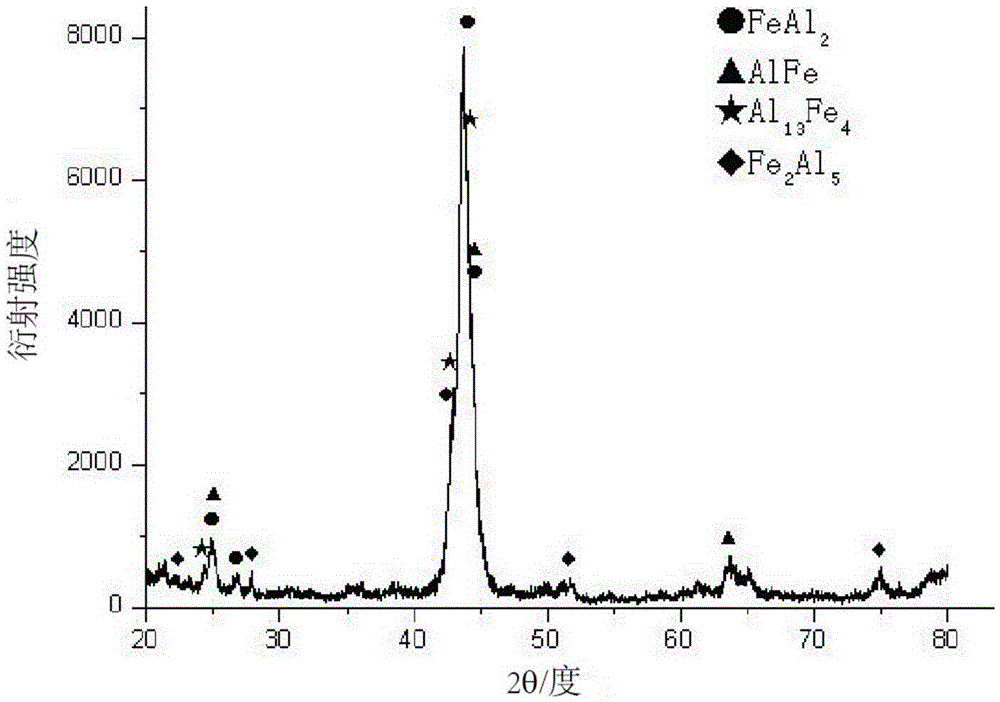

[0096] Picture 10 This is the XRD spectrum of the bottom layer of the Fe-Al microcrystalline self-fluxing alloy layer of this embodiment. It can be seen from the XRD spectrum that the bottom layer is made of Fe 2 Al 5 , FeAl 2 And AlFe phase composition. These phases are all Fe-Al intermetallic compou...

Embodiment 3

[0106] Except that Q235-B plain carbon steel is used as the base material of the multilayer composite ceramic coating, everything else is the same as in Example 1.

[0107] Figure 16 This is the SEM photograph of the cross section of the multi-layer composite ceramic coating used for hot-dip galvanizing of this embodiment. It can be seen from this figure that the inner bottom layer, the intermediate transition layer, and the working layer sealed by the sealing layer on the substrate are well bonded among the sublayers.

[0108] Figure 17 This is the XRD spectrum of the bottom layer of the Fe-Al microcrystalline self-fluxing alloy layer of this embodiment. It can be seen from the XRD spectrum that the bottom layer is made of Al, which is resistant to liquid zinc corrosion, high temperature oxidation, and good thermal conductivity. 5 Fe 2 , FeAl 2 And AlFe phase composition. These phases are all Fe-Al intermetallic compounds, which not only have certain liquid zinc corrosion resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com