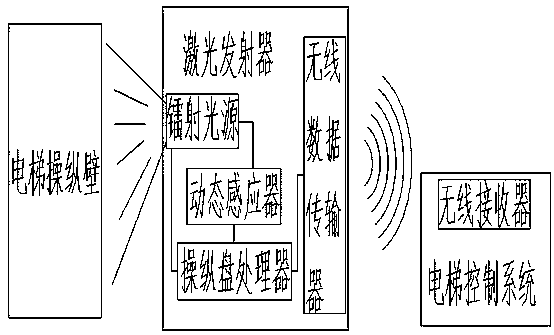

Laser induction type elevator operating panel

A laser induction and control panel technology, applied in elevators, transportation and packaging, etc., can solve the problems of unreliable elevator control, increase failure rate, and complicated operation, and achieve the effect of reliable elevator control, reduction of failure rate, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0018] When passengers enter the elevator, the control panel processor of the laser emitter images an inductive control panel, which is projected onto the control wall of the elevator through the laser light source. The corresponding function sensing points are emitted on the elevator control wall through the laser light source. Passengers see the function buttons on the inductive control panel, and use their fingers to trigger the corresponding button leading to the 18th floor. The dynamic sensor acts on the elevator control wall and has a function sensor point leading to the 18th floor. It is converted into the execution command recognized by the elevator control system, and the information that the elevator needs to go to the 18th floor is transmitted to the elevator control system through the wireless data transmitter. After receiving the information, the elevator control system sends out an execution command. The execution command on the 18th floor closes the elevator doo...

Embodiment example 2

[0020] When the maintenance personnel enter the elevator, the maintenance personnel have the authority to maintain the elevator. The dynamic sensor will automatically identify when the maintenance personnel enter the elevator, confirm that they have the maintenance authority, and transmit the information of the maintenance authority to the laser transmitter through the wireless data transmitter. The control panel processor of the laser transmitter images an inductive control panel, which is projected onto the elevator control wall through the laser light source, and the dynamic sensor of the laser transmitter converts the corresponding functions according to the functions on the projected inductive control panel. The induction point is emitted on the elevator control wall through the laser light source. Because maintenance personnel have maintenance authority, they can trigger the dynamic sensing point through the conversion button on the induction control panel. After the dyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com