Acrylic resin polymer with anti-sag effect and production method thereof

An acrylic resin and polymer technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of adverse effects on the appearance of the coating film, reduce the gloss and vividness of the coating film, and improve the anti-sag performance, control Disadvantages of sagging and the effect of solving sagging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Synthesis of Hydroxy-Acrylic Resin Polymers

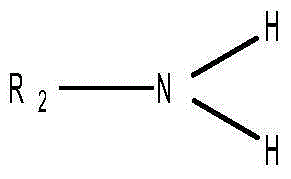

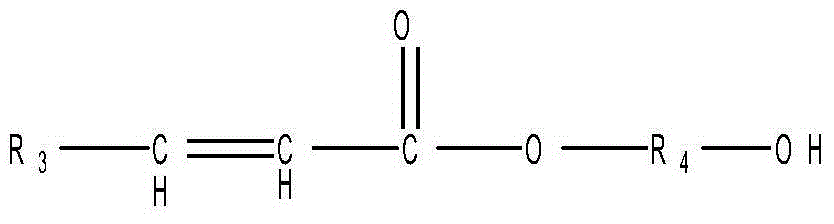

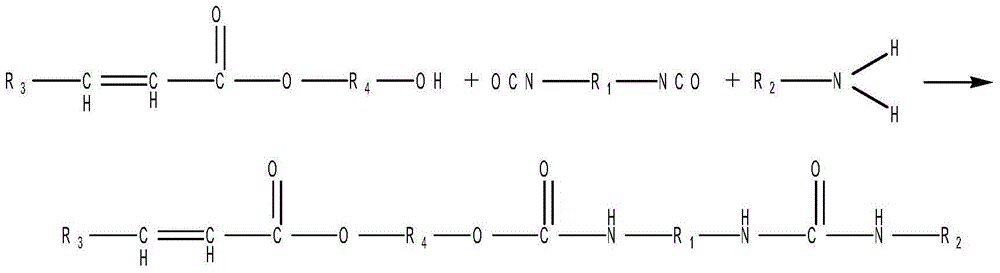

[0046] (1) In a 1000ml four-neck glass flask equipped with an electric stirrer, reflux condenser and thermometer, add 365g of xylene, add 174.16g of toluene diisocyanate, control the temperature at 50°C, add dropwise 59.11g of n-propylamine for 1 hour Continue to control the temperature at 50°C, add 131 propylene hydroxypropyl ester dropwise, drop it at a constant speed for 2 hours, keep it at 50°C for 2 hours after the drop, filter and discharge the material, and prepare the preform with amide bond and carbon-carbon double bond. Polymer spare.

[0047] (2) In a 2000ml four-necked glass flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 300g of xylene, raise the temperature to 120°C-140°C, and add dropwise 100g of methyl methacrylate, A mixed solution of 120g n-butyl acrylate, 130g hydroxypropyl acrylate, 200g styrene and 10g dibenzoyl peroxide. At the same time, 100 g of the prepolymer solu...

Embodiment 2

[0049] Synthesis of Hydroxy-Acrylic Resin Polymers

[0050] Toluene diisocyanate is replaced with diphenylmethane diisocyanate, and the reaction device, reactant, operation method and steps are the same as in Example 1.

Embodiment 3

[0052] Synthesis of Hydroxy-Acrylic Resin Polymers

[0053] Replacing n-propylamine with cyclohexylamine, the reaction device, operation method and steps are the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap