Processing technology of waterproof coating for building

A processing technology and building waterproofing technology, which is applied to coatings, mixers with rotating stirring devices, mixers, etc., can solve problems such as inconvenient use, easy skinning, and insufficient stirring and mixing effects, and achieve full mixing and mixing , Increased tensile breaking strength, improved anti-sag performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

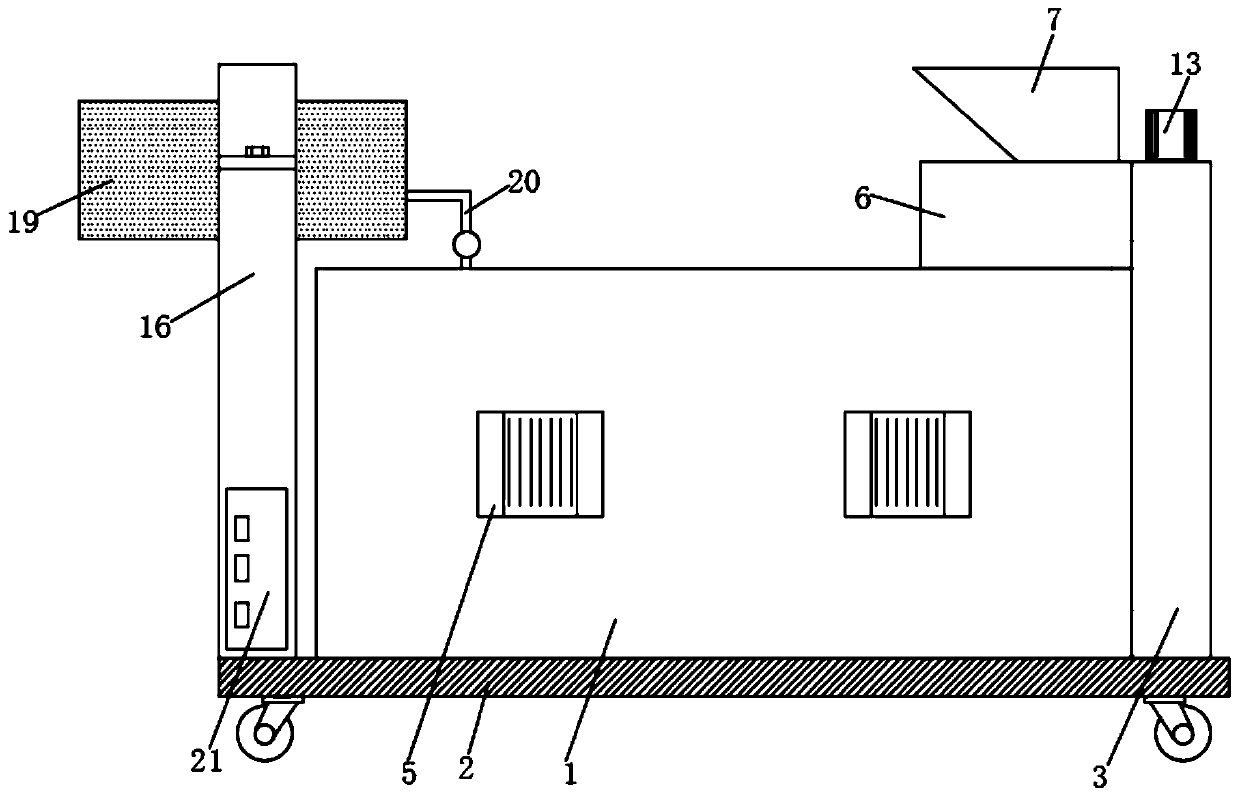

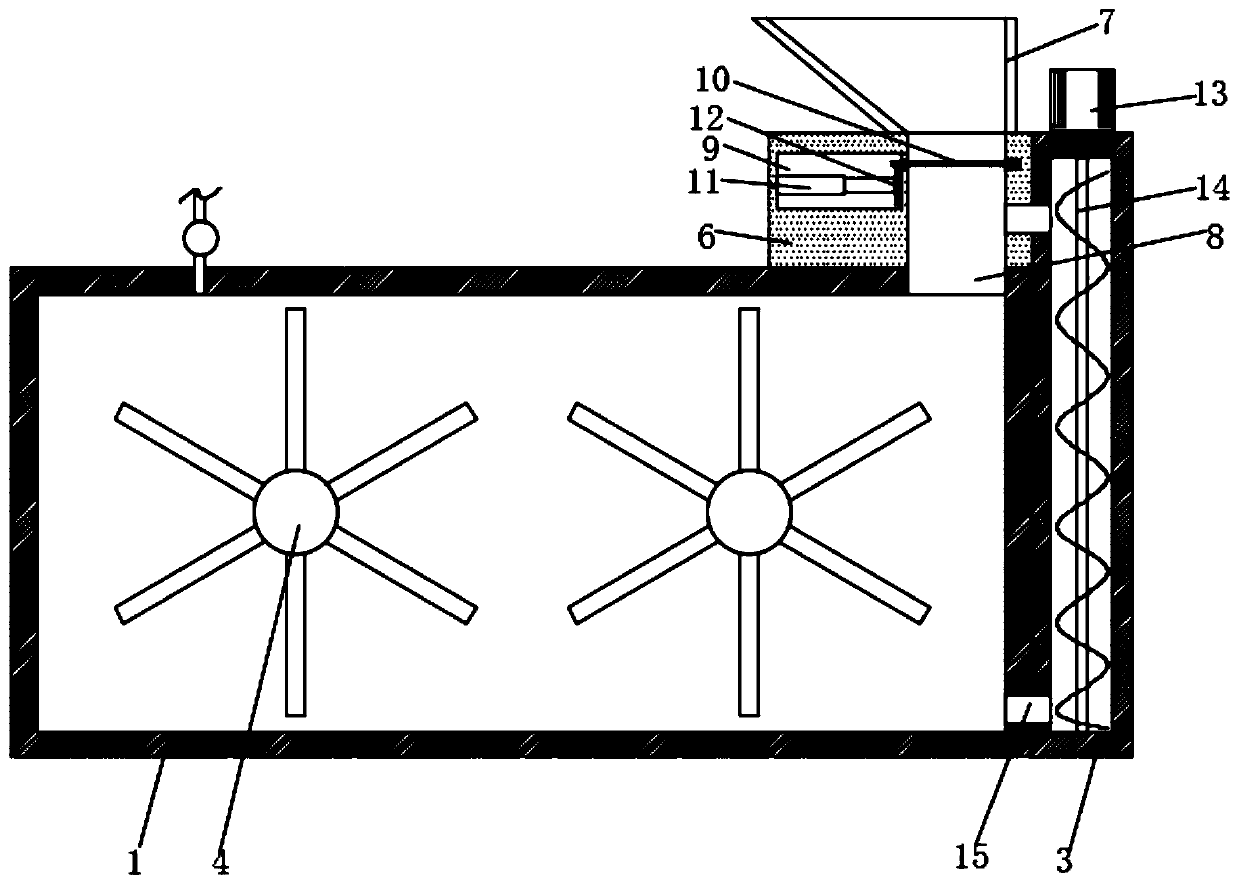

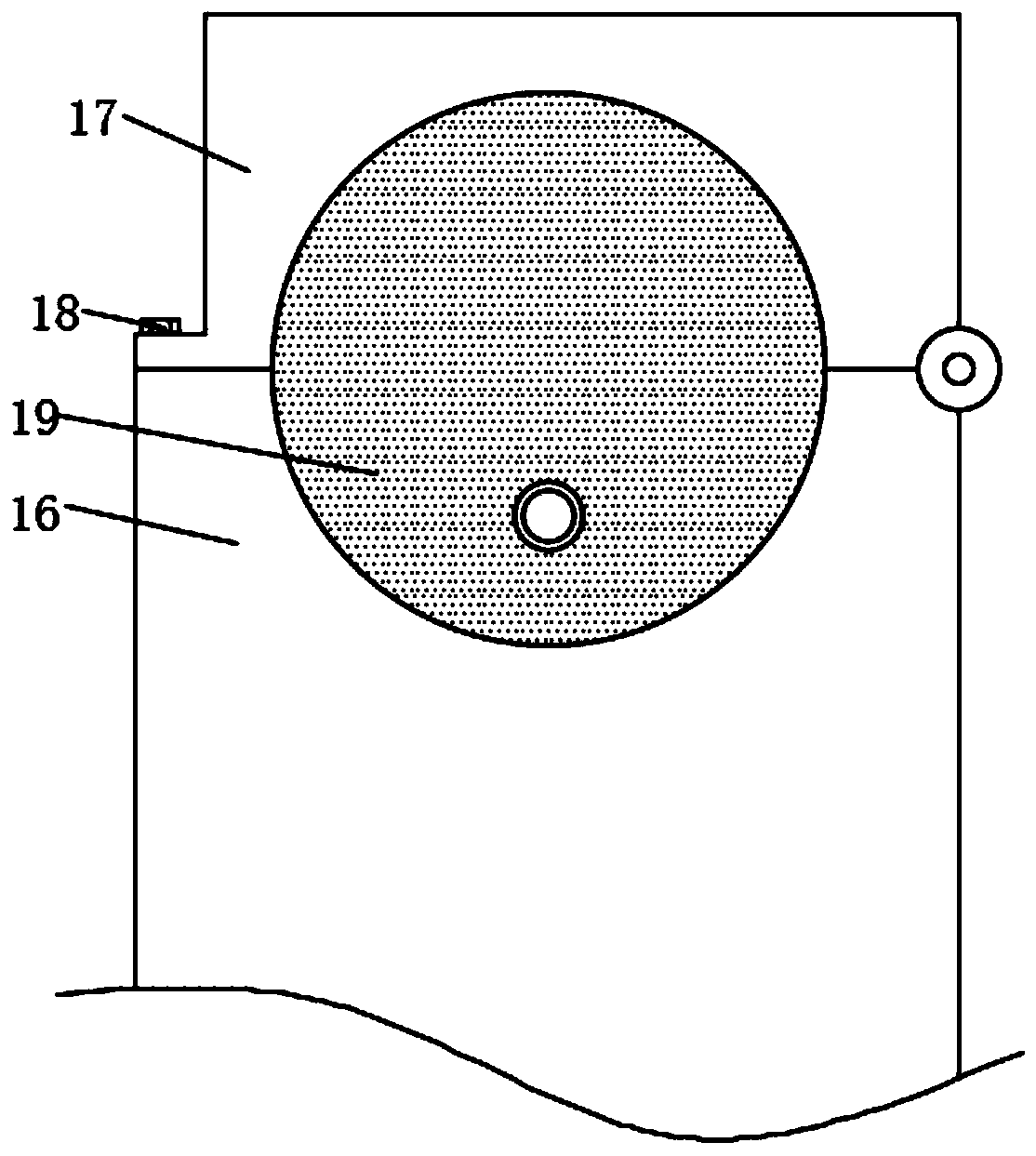

Method used

Image

Examples

Embodiment 1

[0040] A processing technology for building waterproof paint, comprising the following steps:

[0041] A: Material preparation: Weigh raw materials according to the following weight ratio, heavy calcium powder 30%, nano-calcium carbonate 35%, graphene 5%, nano-titanium dioxide 1%, defoamer 0.5%, thickener 0.8%, preservative 0.4 %, sodium bentonite 3.5%, antifungal agent 0.2%, and the balance is three nail phosphate;

[0042] B: Drying: Dry the nano-calcium carbonate at a temperature of 112°C to make its moisture content ≤ 0.76‰, and dry the heavy calcium carbonate to make its moisture content ≤ 0.46‰;

[0043] C: Ball milling: put heavy calcium powder, nano-calcium carbonate, graphene, nano-titanium dioxide and sodium bentonite into the ball mill for ball milling. The ball milling time is 22 minutes.

[0044] D: Stirring and mixing: Put the materials after ball milling into the stirring device, and add defoamer, thickener, preservative, anti-fungal agent and three-nail phosph...

Embodiment 2

[0047] A processing technology for building waterproof paint, comprising the following steps:

[0048] A: Material preparation: Weigh raw materials according to the following weight ratio, heavy calcium powder 32%, nano calcium carbonate 32%, graphene 10%, nano titanium dioxide 0.8%, defoamer 0.65%, thickener 0.6%, preservative 0.6 %, 3% sodium bentonite, 0.3% antifungal agent and the balance is three nail phosphate;

[0049] B: Drying: Dry the nano-calcium carbonate at a temperature of 115°C to make its moisture content ≤0.76‰, and dry the heavy calcium carbonate to make its moisture content ≤0.46‰;

[0050] C: Ball milling: put heavy calcium powder, nano-calcium carbonate, graphene, nano-titanium dioxide and sodium bentonite into the ball mill for ball milling. The ball milling time is 25 minutes.

[0051] D: Stirring and mixing: put the ball milled material into the stirring device, and add defoamer, thickener, preservative, anti-fungal agent and three-nail phosphate greas...

Embodiment 3

[0054] A processing technology for building waterproof paint, comprising the following steps:

[0055] A: Material preparation: Weigh raw materials according to the following weight ratio, heavy calcium powder 35%, nano calcium carbonate 30%, graphene 14%, nano titanium dioxide 0.5%, defoamer 0.8%, thickener 0.4%, preservative 0.8 %, sodium bentonite 2.5%, antifungal agent 0.4%, and the balance is three nail phosphate;

[0056] B: Drying: Dry the nano-calcium carbonate at a temperature of 119°C to make its moisture content ≤ 0.76‰, and dry the heavy calcium carbonate to make its moisture content ≤ 0.46‰;

[0057] C: Ball milling: put heavy calcium powder, nano-calcium carbonate, graphene, nano-titanium dioxide and sodium bentonite into the ball mill for ball milling. The ball milling time is 29 minutes.

[0058] D: Stirring and mixing: put the ball milled material into the stirring device, and add defoamer, thickener, preservative, anti-fungal agent and three nail phosphate g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap