A cold recycling mixing tank for emulsified asphalt

A technology of emulsified asphalt and cold recycling, used in roads, road repair, roads, etc., can solve the problems of overflow, insufficient mixing, low mixing efficiency, etc., and achieve the effect of reducing waste and sufficient mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

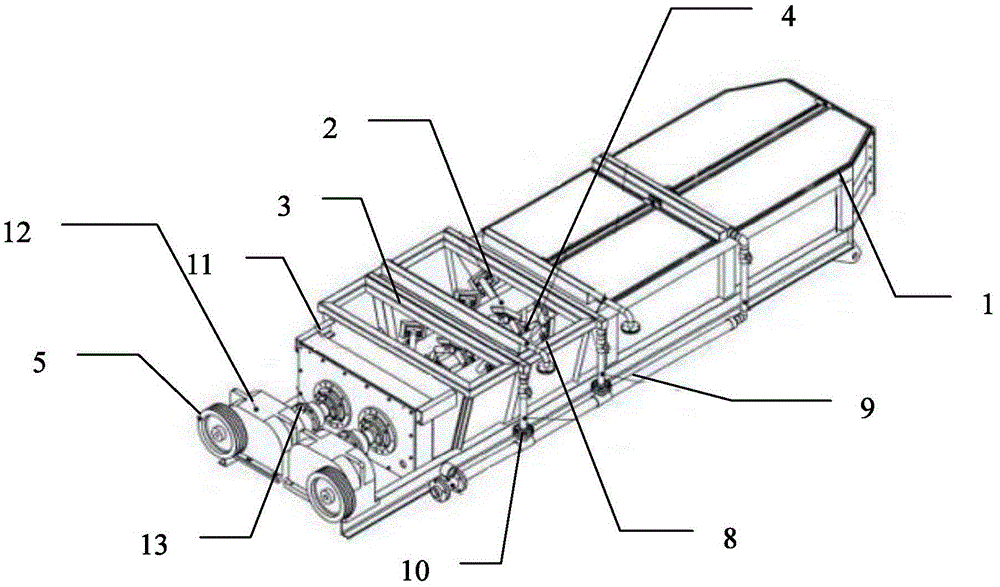

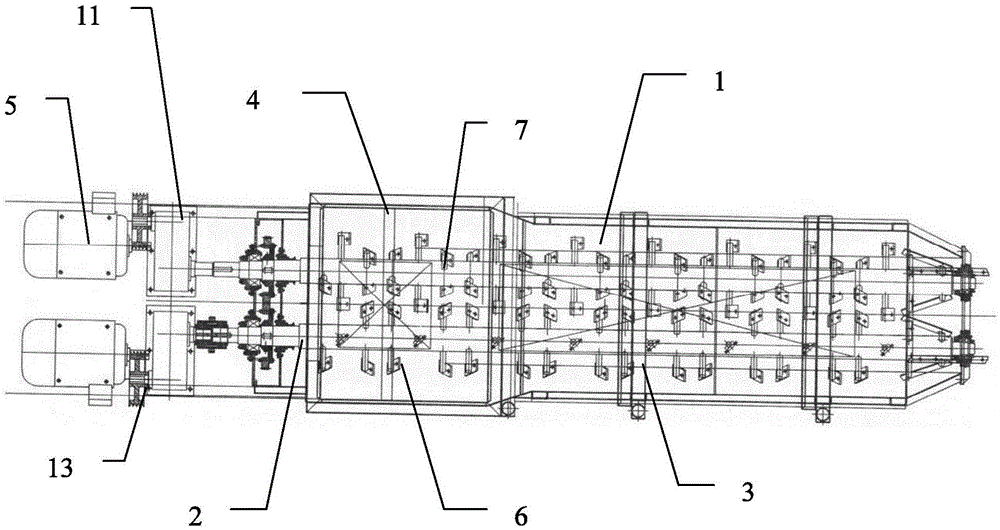

[0018] like figure 1 and figure 2 As shown, the present invention provides a kind of emulsified asphalt factory mixing cold regeneration mixing tank, comprising:

[0019] Mixing cylinder 1, which is a box structure with an upper end opening, and a plurality of water supply pipes 3 and asphalt pipes 4 are installed at the opening of the mixing cylinder, and the water supply pipes and asphalt pipes are arranged horizontally and staggered at the opening of the mixing cylinder , the setting direction of the water supply pipe and the asphalt pipe is perpendicular to the length direction of the mixing tank;

[0020] A pair of stirring shafts 2, which are arranged in parallel inside the mixing tank, one end of the pair of stirring shafts all extends out of the side wall of the mi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap