Sandy soil laying leveling device and sandy soil laying method

A technology of sand and traction device, applied in construction, building structure and other directions, can solve the problems of inconsistent contact strength between marble or floor tiles and sand layer, difficulty in ensuring uniform hardness of sand and gravel laying, cracking or breaking of brick bodies, etc. Labor efficiency and construction quality, avoiding uneven hardness, and the effect of sandy soil leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings.

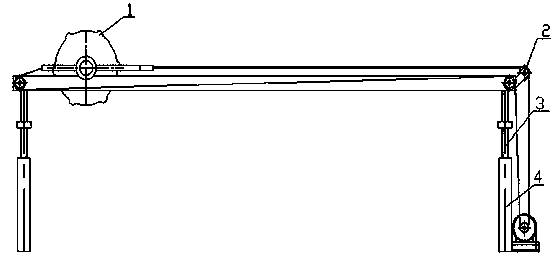

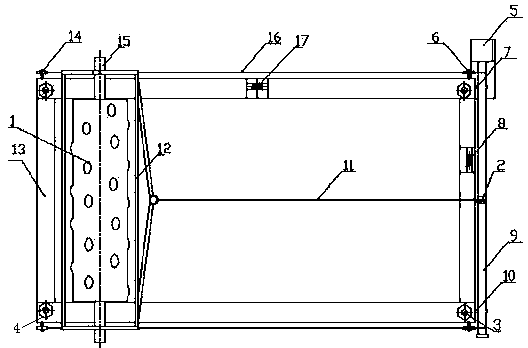

[0015] Such as figure 1 , figure 2 Shown is a preferred embodiment, a leveling device for laying sand and soil, including roller 1, pulley 2, adjustment mechanism 3, column 4, motor and control device 5, pulley 6, bracket 7, longitudinal level 8, wire storage Bucket 9, bracket 10, traction wire rope 11, traction frame 12, frame 13, pulley 14, roller shaft 15, traction wire rope 16 and horizontal level 17, the column 4 on four corners is identical, and pulley 6 is figure 2 There are two in the middle and the upper and lower, and the pulley 14 is figure 2 There are two in the upper and lower. The frame 13 is a rectangular structure, and the material can be wood, steel or the like. Horizontal level 17 and longitudinal level 8 are respectively installed in the horizontal frame and longitudinal frame middle part of frame 13, and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com