Drillable casing floating hoop floating shoe device

A technology of floating shoes and hoops, which is applied in the direction of wellbore/well valve devices, earthwork drilling, wellbore/well components, etc. It can solve the influence of valve core sealing performance and forward and reverse pressure bearing capacity, PDC bit two Difficulties in drilling in the first spud and restrictions on drilling progress, etc., to achieve the effects of reducing cementing accidents, shortening drilling cycle, and reducing drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

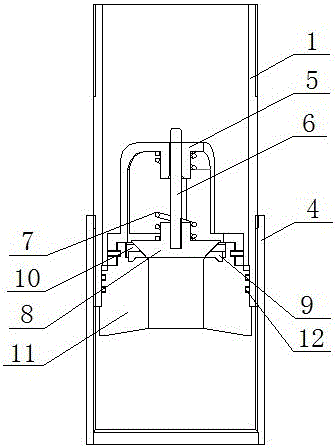

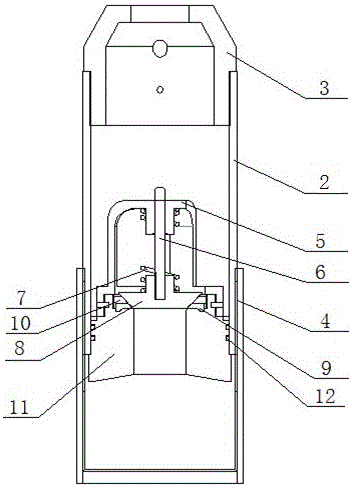

[0021] The structure diagram of the floating hoop in the drillable casing floating hoop shoe is as follows: figure 1 As shown, the schematic diagram of the floating shoe structure is shown in figure 2 As shown, it at least includes a floating hoop shell 1 and a floating shoe shell 2, and the upper edge of the floating hoop shell has connecting threads, wherein the upper end of the floating shoe shell 2 is connected with a drainage cover 3 through its connecting thread, and the floating hoop The lower edge of the floating shoe shell has threads on both sides inside and outside, the lower edge of the floating hoop floating shoe shell is connected to the collar 4 through its external thread, and the lower edge of the floating hoop floating shoe shell is connected to the valve seat 11 through its internal thread, and the valve seat The upper part of 11 is threadedly connected with spring seat 5, and the axial center position of spring seat 5 and valve seat 11 has a through hole. ...

Embodiment 2

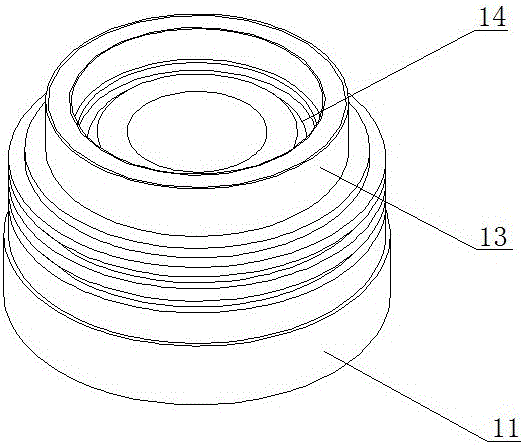

[0024] A sealing ring 12 is also sleeved between the valve seat 11 and the floating hoop floating shoe housing to seal the connection. The structure of the valve seat 11 is as follows: image 3 As shown, the outside of the middle part of the valve seat 11 is an external thread connected with the lower edge of the floating hoop floating shoe housing and an annular groove for placing the sealing ring 12. The upper part of the valve seat 11 has an annular convex edge 13, and the inner side of the annular convex edge is an annular The pressure cap fixing groove 14, the pressure cap 9 is crimped in the pressure cap fixing groove 14, and a gasket 10 is also fixed between the upper surface of the pressure cap 9 and the inner side wall of the annular convex edge.

[0025] The structure of pressure cap 9 is as Figure 4 As shown, the pressure cap 9 is an annular structure, and the annular inner wall of the pressure cap 9 is a slope with a closed end. Fixing hole for valve stem 6, see ...

Embodiment 3

[0028] The structure of spring seat 5 is as Figure 6 As shown, it is composed of a base 15, an upper spring seat 16, and a fixed rod 17; wherein the base 15 is an annular structure, and the inner wall of the base 15 is an internal thread, and the base 15 protrudes along the outer wall of the valve seat 11 through its internal thread. The upper end of the base 15 is fixedly connected with the upper spring seat 16 through the fixed rod 17, wherein there are three fixed rods 17, the upper spring seat 16 is coaxial with the ring-shaped base 15, and the axial center position of the upper spring seat 16 is provided with a socket The through hole of the valve rod 6, the upper spring seat 16 bottom is a spring holder, and the spring 7 upper end is fixedly connected with the spring holder.

[0029] The cement slurry enters the top through the gap between the spring seat 5 three fixed rods after the valve seat 11 is pushed away.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com