Installation structure of a car carbon canister

A technology of installation structure and carbon canister, which is applied to the charging system, adding non-fuel substances to fuel, engine components, etc., can solve the problems of inconvenient installation and disassembly, and achieves low requirements for processing accuracy, simple structure, and convenient production. The effect of consistency control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the drawings and embodiments:

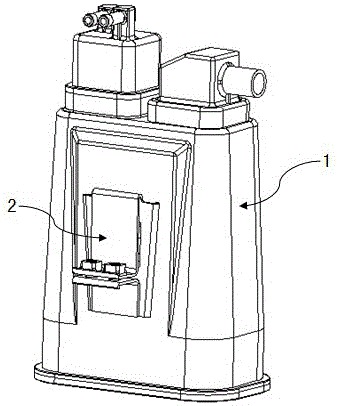

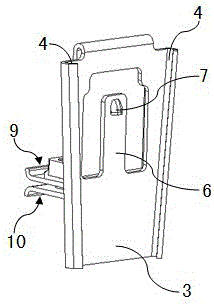

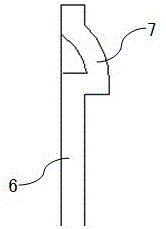

[0017] Such as figure 1 The installation structure of the car carbon canister shown includes carbon canister 1 and mounting bracket 2, see figure 2 , 5 The mounting bracket 2 includes a plate-shaped bracket body 3. The two sides of the bracket body 3 are folded toward the front to form guide grooves 4 that penetrate the entire side edges of the bracket body. The outer wall of the carbon canister 1 is gradually narrowed. Two guide rails 5 corresponding to the guide grooves 4 of the mounting bracket are provided on the outer wall of the canister 1, and the distance between the two guide rails 5 gradually narrows from top to bottom. The guide rail 5 is divided into two sections longitudinally, so that each guide rail 5 is composed of upper and lower sub-rails spaced apart. The carbon canister 1 is inserted into the guide groove 4 of the bracket body 3 through the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com