Integrated motor pump for hydraulic system

A hydraulic system and motor pump technology, applied in the direction of liquid variable capacity machinery, pumps, mechanical equipment, etc., can solve the problems that it is difficult to achieve zero leakage and cannot meet long-term storage, so as to reduce power consumption, avoid long-term high-speed operation, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

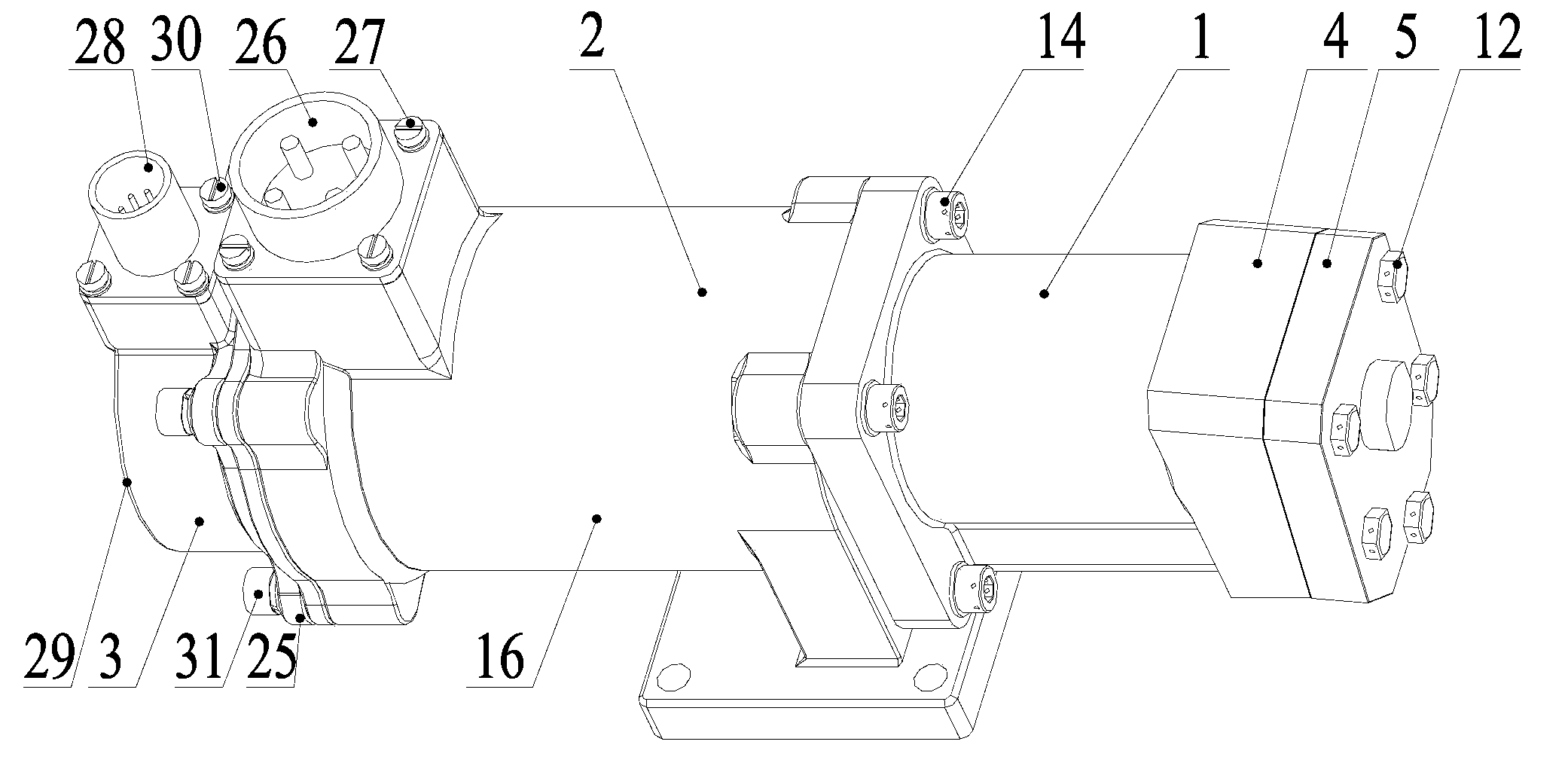

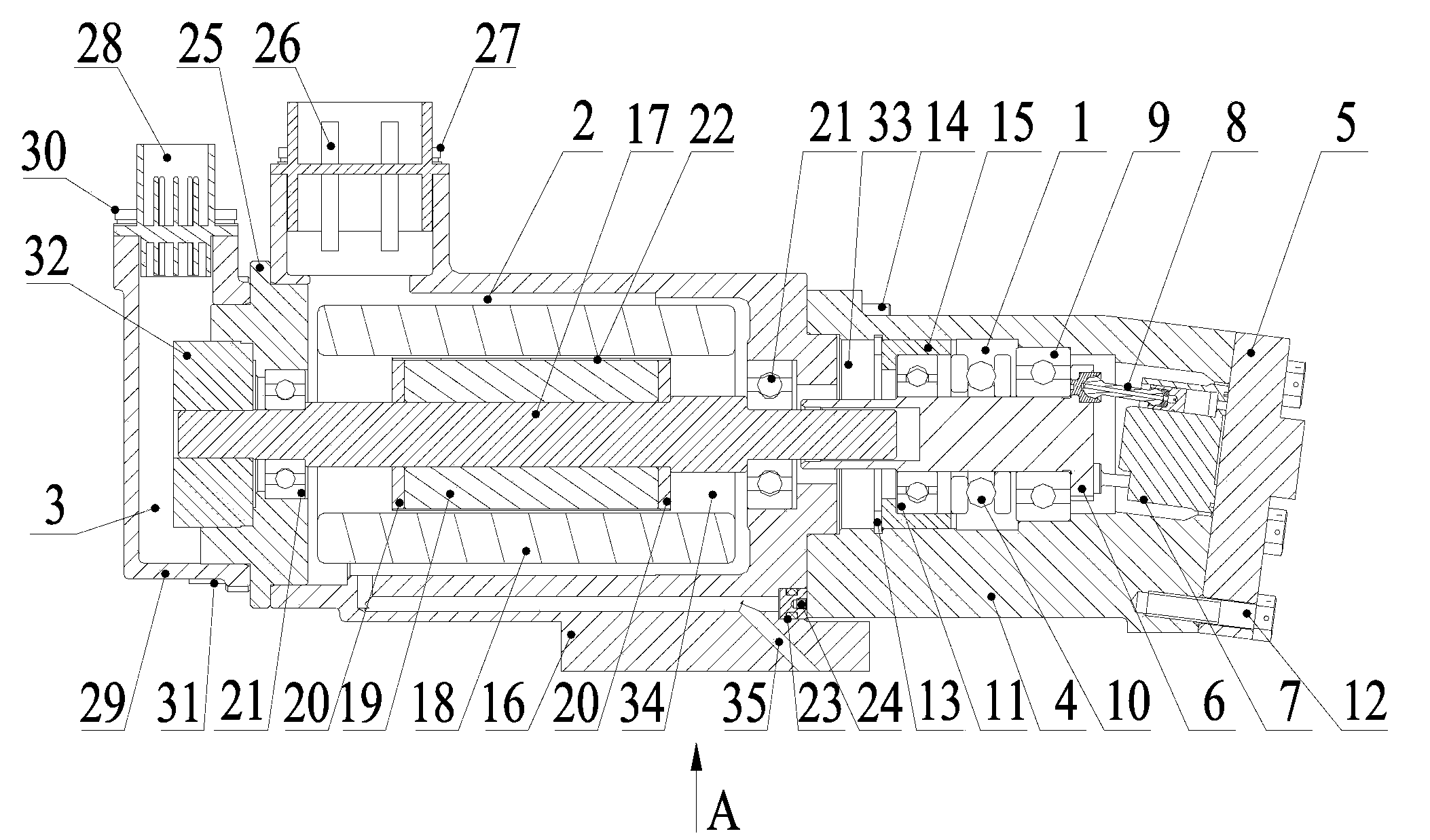

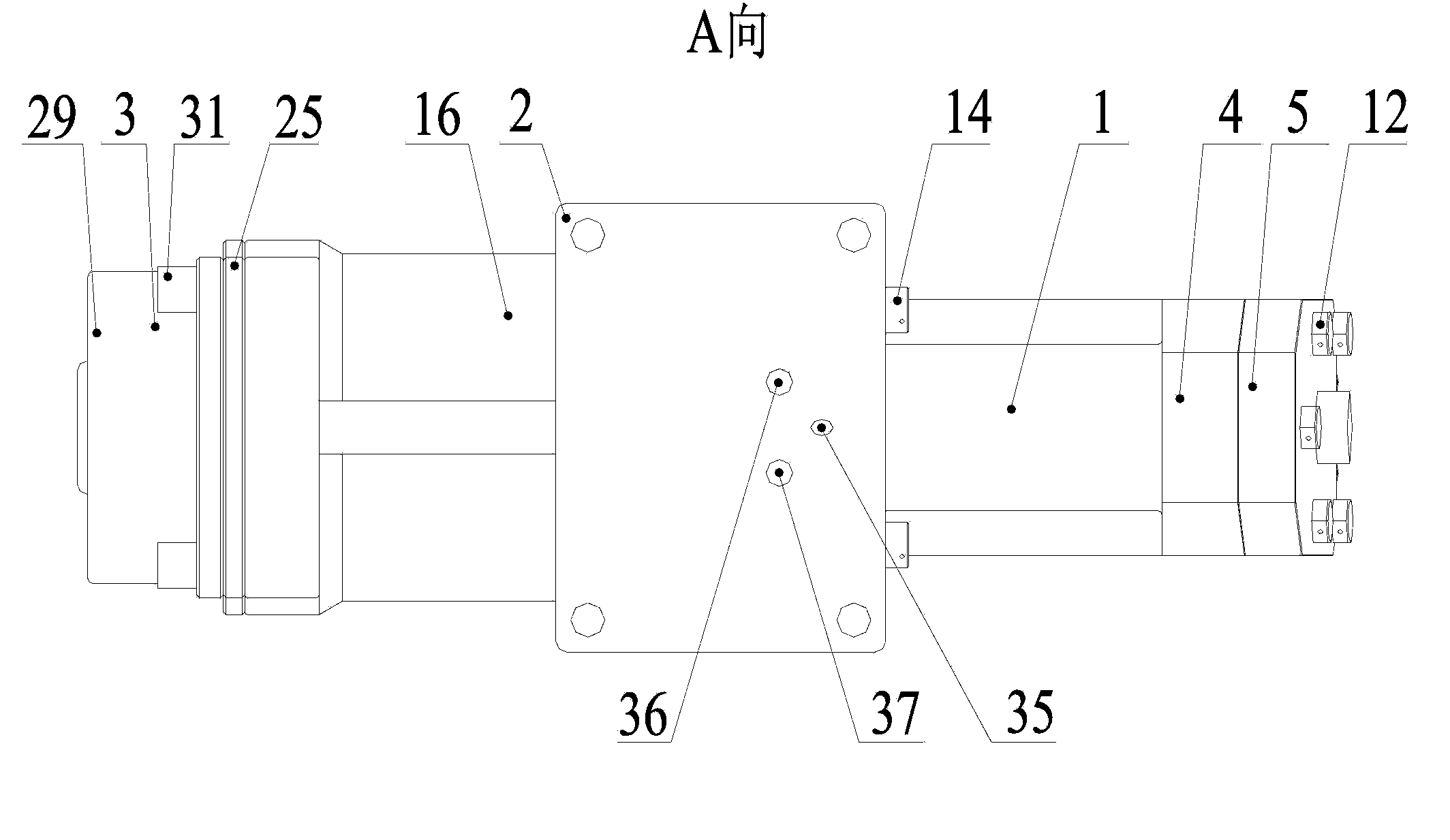

[0021] Such as figure 1 with figure 2 As shown, a motor pump for a hydraulic system provided by the present invention includes: a plunger pump assembly 1 , a motor assembly 2 and a resolver assembly 3 .

[0022] Such as figure 1 with figure 2 As shown, the plunger pump assembly 1 includes a pump housing 4, an oil separator 5, a pump main shaft 6, a pump rotor 7, a plunger assembly 8, a first deep groove ball bearing 9, a thrust ball bearing 10, a second deep groove ball bearing Bearing 11, first screw 12, second screw 14, circlip 13, bushing 15. The pump casing 4 of the plunger pump assembly 1 is fixedly connected to the motor casing 16 of the motor assembly 2 by four second screws 14 , and the pump casing 4 and the oil separator 5 are fixedly connected by four first screws 12 . Such as figure 2 As shown, the pump main shaft 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com