Hydraulic motor starting performance testing device and method

A technology of hydraulic motor and starting performance, applied in fluid pressure actuating device, fluid pressure actuating system testing, mechanical equipment, etc., can solve the problems of complicated operation, complex structure, large investment, etc., to ensure accuracy and simple structure , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

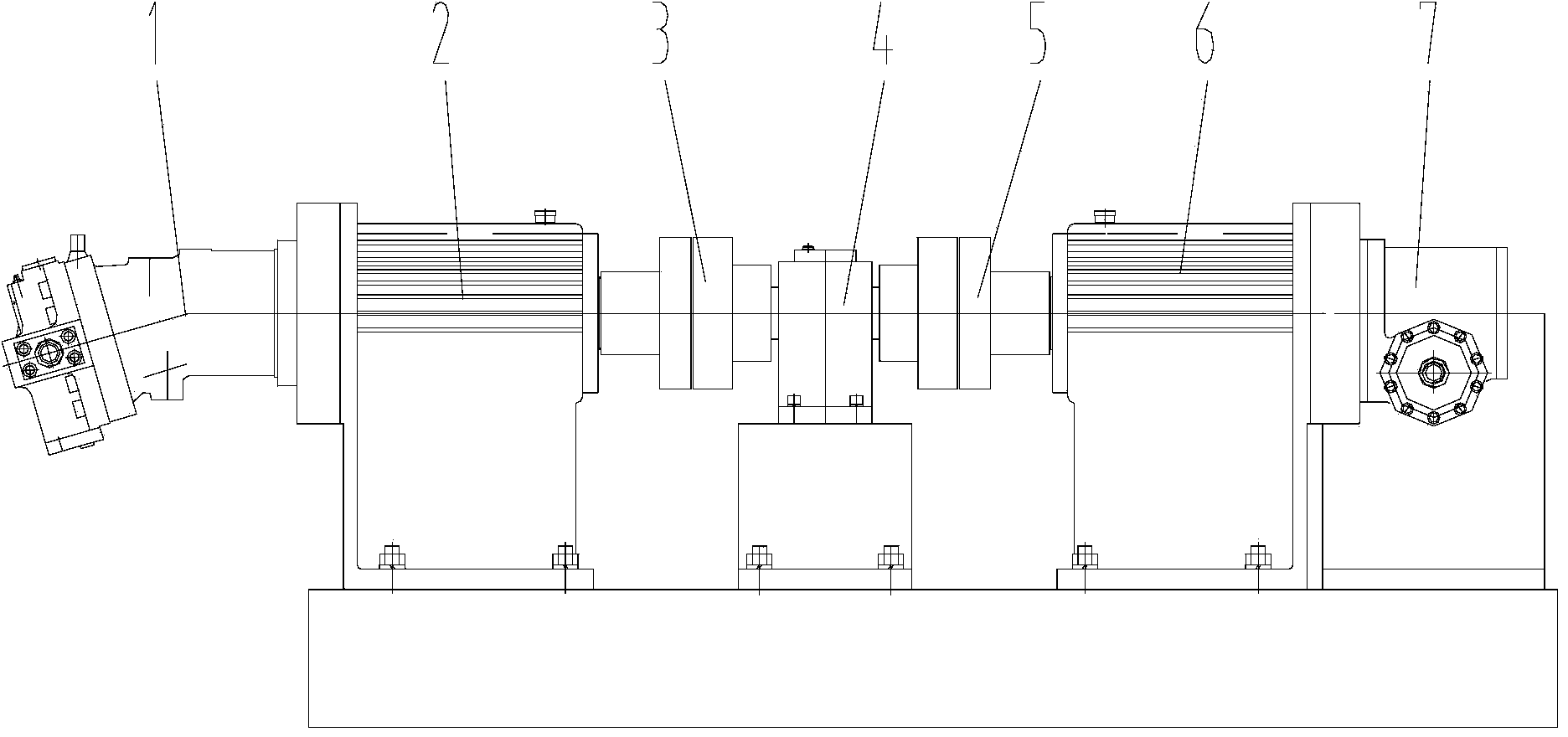

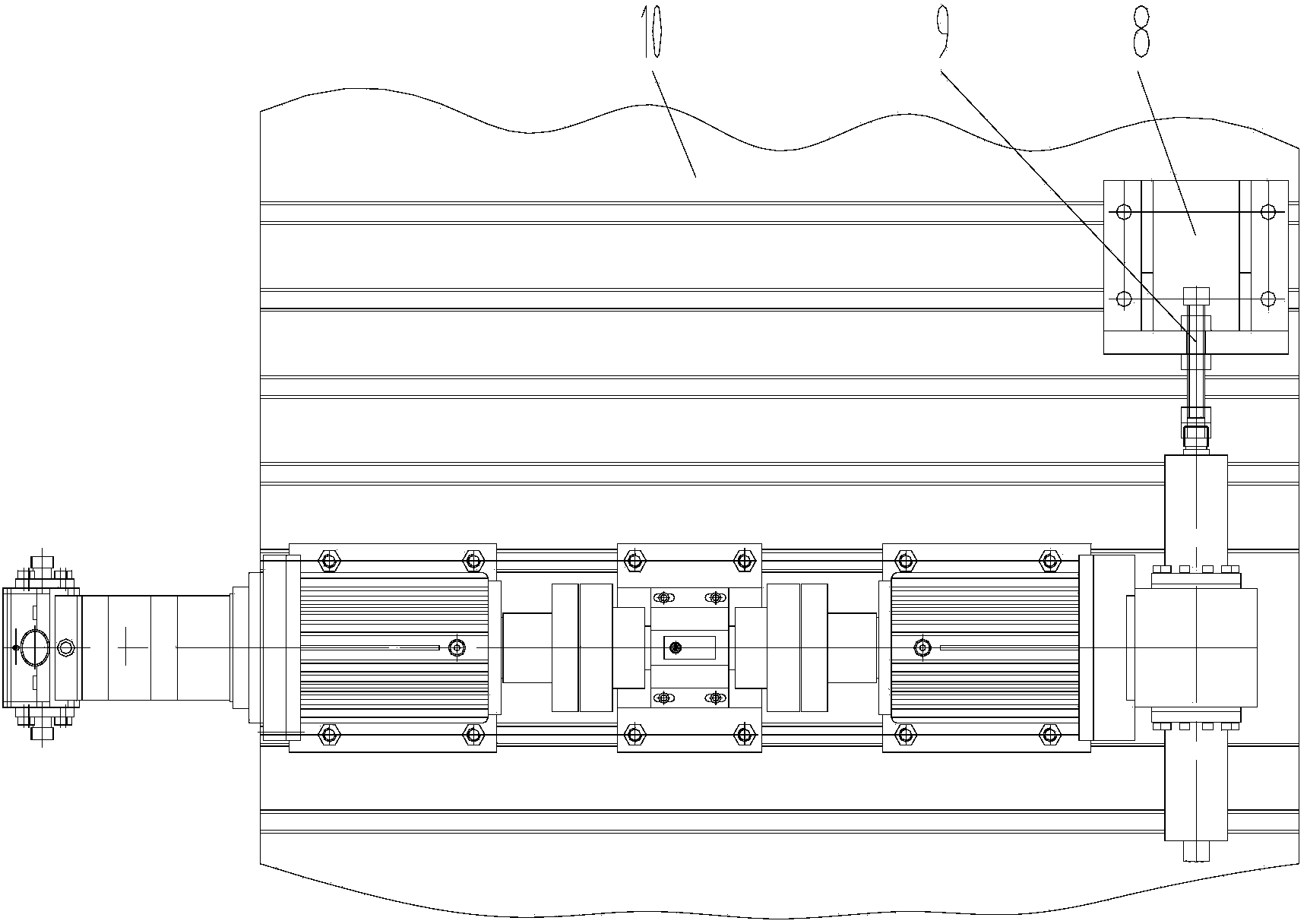

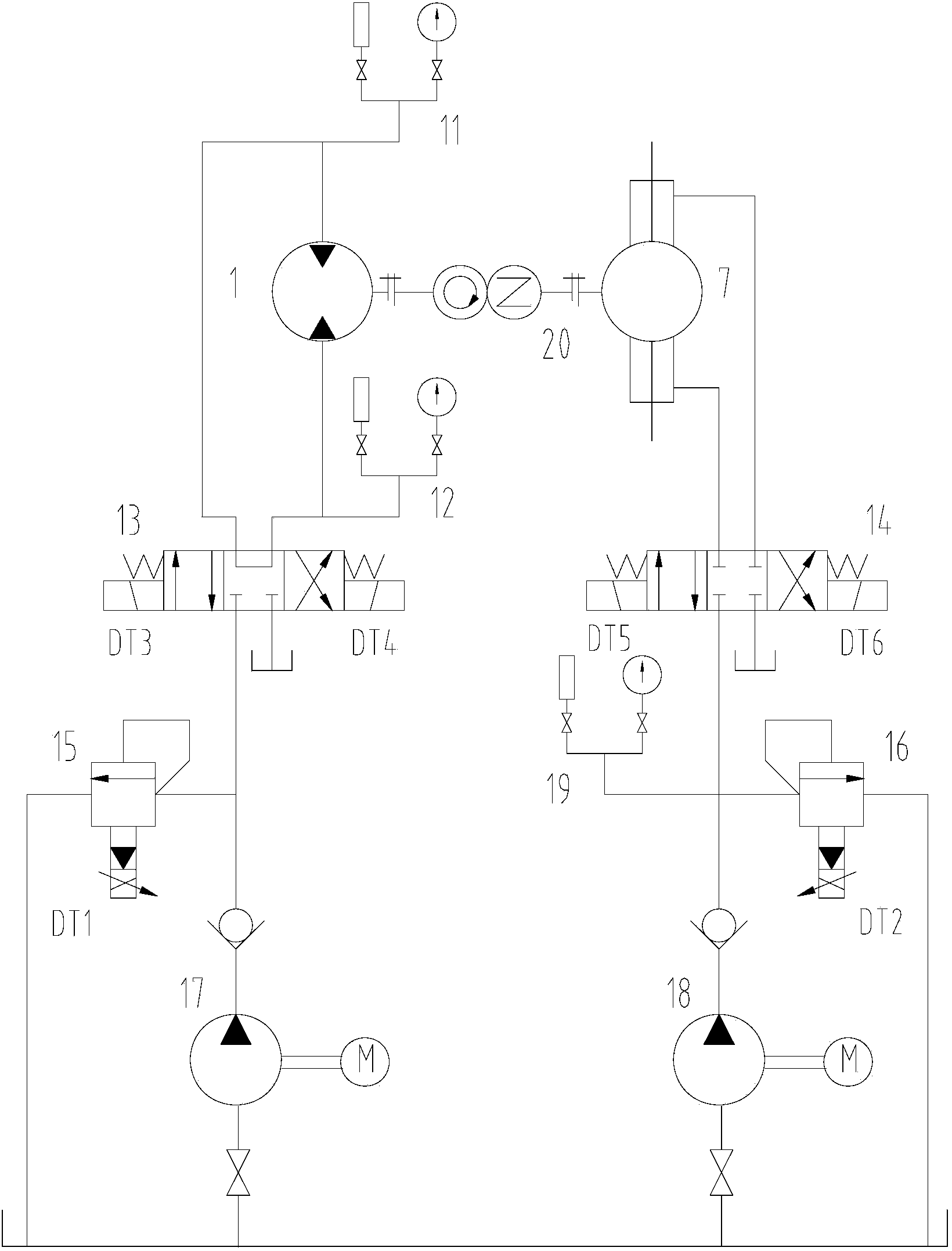

[0028] See Figure 1 ~ Figure 4 , a testing device for the starting performance of a hydraulic motor, comprising a swing hydraulic cylinder 7, a hydraulic system and an installation platform 10, the installation platform is provided with a test frame 4, a first transmission bracket 2, a second transmission bracket 6 and a limit bracket 8, wherein, the test frame 4 is provided with a torque speed sensor 20; the first transmission bracket 2 and the second transmission bracket 6 are respectively located on both sides of the test frame 4, and are connected to the test frame 4 through a coupling. The transmission shaft of the torque speed sensor 20 is connected; the first transmission bracket is connected with the output shaft of the tested hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com