Flexible shaft for car selection and shifting

A technology for shifting gears and flexible shafts, which is applied in the direction of rotating motion shafts, etc., can solve problems such as affecting the driving safety of vehicles, the vehicle cannot be shifted normally, and the flexible shafts are baked and deformed, so as to achieve the effect of safe vehicle driving and good heat insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific embodiments.

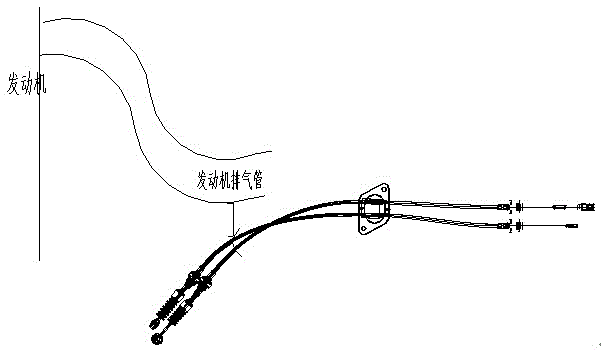

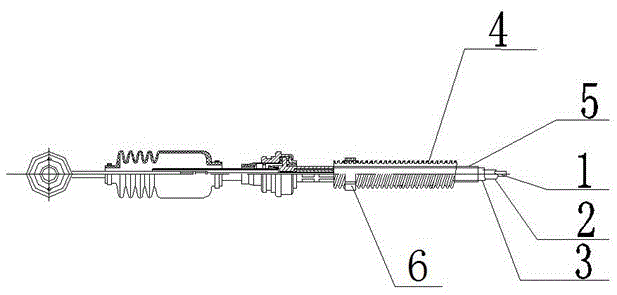

[0019] Such as figure 2 As shown, a flexible shaft for selecting and shifting automobiles includes a flexible shaft body, the flexible shaft body includes a flexible shaft core wire 1, the outer surface of the flexible shaft core wire 1 is covered with a flexible shaft nylon lining 2, and the flexible shaft nylon liner The outer surface of the inner liner 2 is covered with a flexible shaft plastic shell 3, and the outer surface of the flexible shaft plastic shell 3 is wrapped with a rubber sheath 5, and the outer surface of the rubber sheath 5 is wrapped with heat-insulating aluminum platinum 4, and the heat-insulated aluminum platinum 4 is Double-layer heat-insulating aluminum platinum, with fibers for heat insulation sandwiched between the double-layer heat-insulating aluminum platinum, and the surface of the heat-insulating aluminum platinum 4 is arranged in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com