Steam combustion-supporting burner

A combustion-supporting, burner technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of wasting fuel, not in line with energy conservation and environmental protection, and achieve the effect of temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

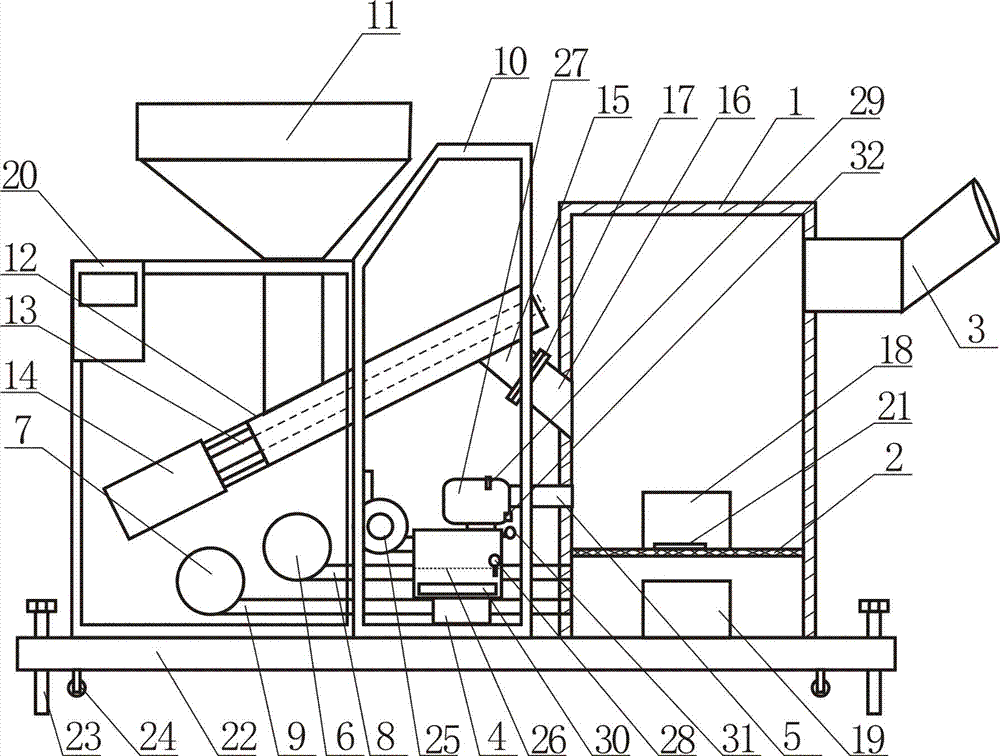

[0021] Such as figure 1 As shown, the steam combustion-supporting burner is mainly composed of a furnace body 1, a furnace plate 2, a fan, a steam generator, a smoke exhaust pipe 3 and a feeding device. The furnace plate 2 is located in the furnace body 1, and the furnace body 1 A furnace door 18 and a slag discharge door 19 are arranged on the top, and the smoke exhaust pipe 3 is arranged on the side upper part of the furnace body 1 . There are two air inlets on the furnace body 1 below the furnace tray, one is a high-pressure air inlet, and the other is a low-pressure air inlet; the fan is provided with two, a high-pressure fan 6 and a low-pressure fan 7, and the high-pressure The fan 6 communicates with the high-pressure air inlet on the furnace body 1 through the high-pressure air supply pipe 8 , and the low-pressure fan 7 communicates with the low-pressure air inlet on the furnace body 1 through the low-pressure air supply pipe 9 .

[0022] Feeding device is mainly made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com