Experimental device for determination of periodic heat transfer coefficients

A technology of heat transfer coefficient and experimental device, applied in the direction of material thermal development, etc., can solve the problems of deformation of cooling steel plate and inability to continuously cool, and achieve the effects of stable rotation, wide adjustment range and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

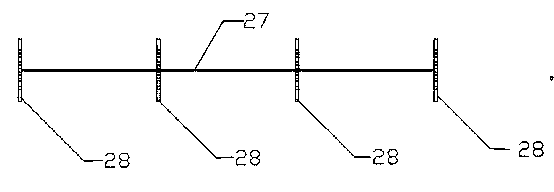

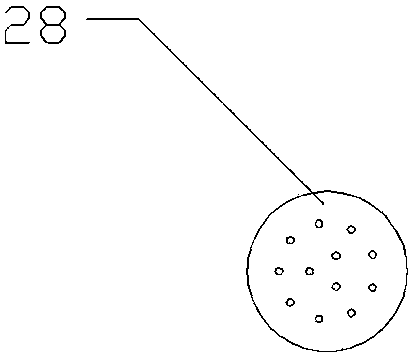

[0040] The invention provides an experimental device for measuring the periodic heat transfer coefficient, such as Figure 7 As shown, it includes a rotating steel drum 1, and a transmission device and a speed regulating device connected with the rotating steel drum. A nozzle 2 is installed above the rotating steel drum, and the nozzle is respectively connected to the air source 5 and the The water source 6 is connected, and a thermocouple 7 and a heating device 8 are installed in the rotating steel drum. The experimental device is provided with a temperature signal collection device 9, and the thermocouple and the temperature signal collection device are electrically connected.

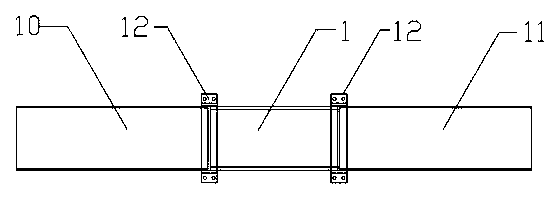

[0041] Such as figure 1 As shown, the left and right support barrels 10 and the right support barrels 11 are respectively installed on the left and right sides of the rotating steel drum. Figure 7As shown, the inside of the left support barrel, the rotating steel barrel and the right support barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com