Direct lead wire grounding wire mounting and dismounting device

A wire grounding and lead wire technology is applied in the field of direct lead wire ground wire assembly and disassembly devices, which can solve the hidden dangers of knife gate porcelain bottles, difficulty in assembling and dismantling the ground wire, and damage to operators, so as to eliminate potential safety hazards, ensure reliable connection, and reduce errors. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

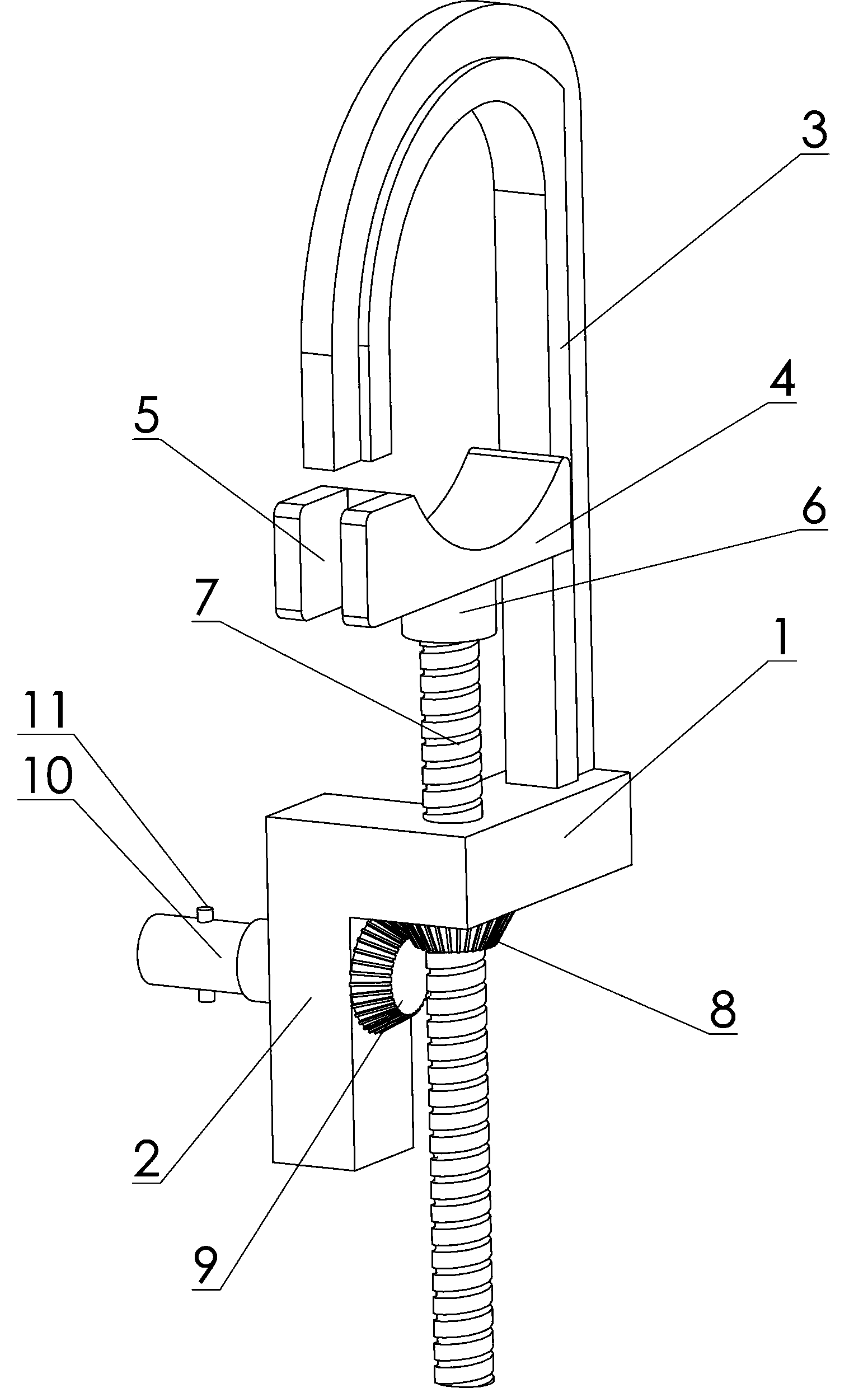

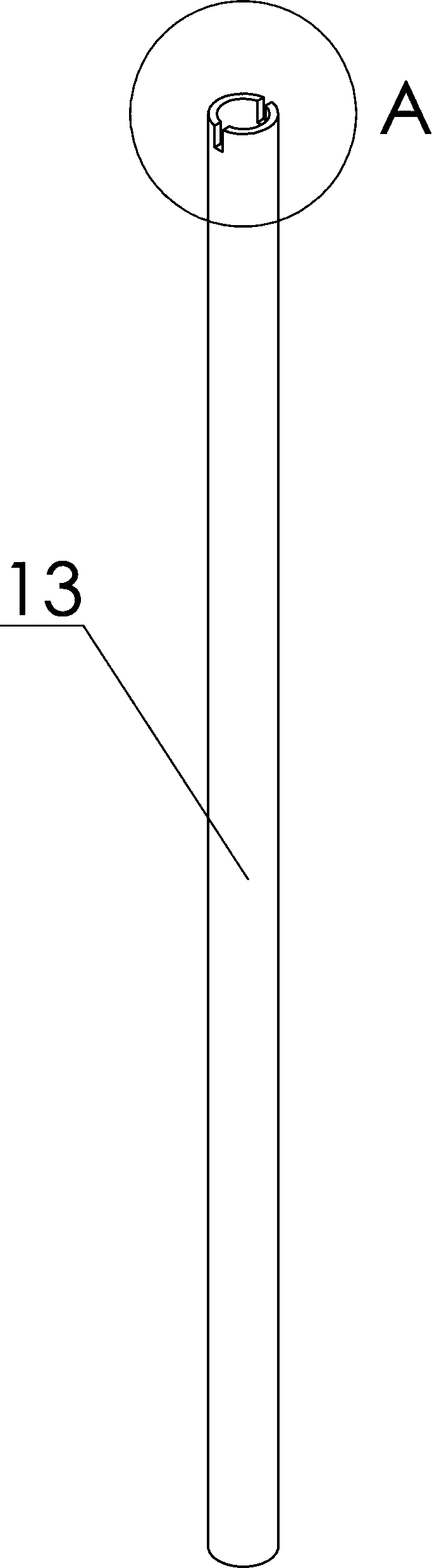

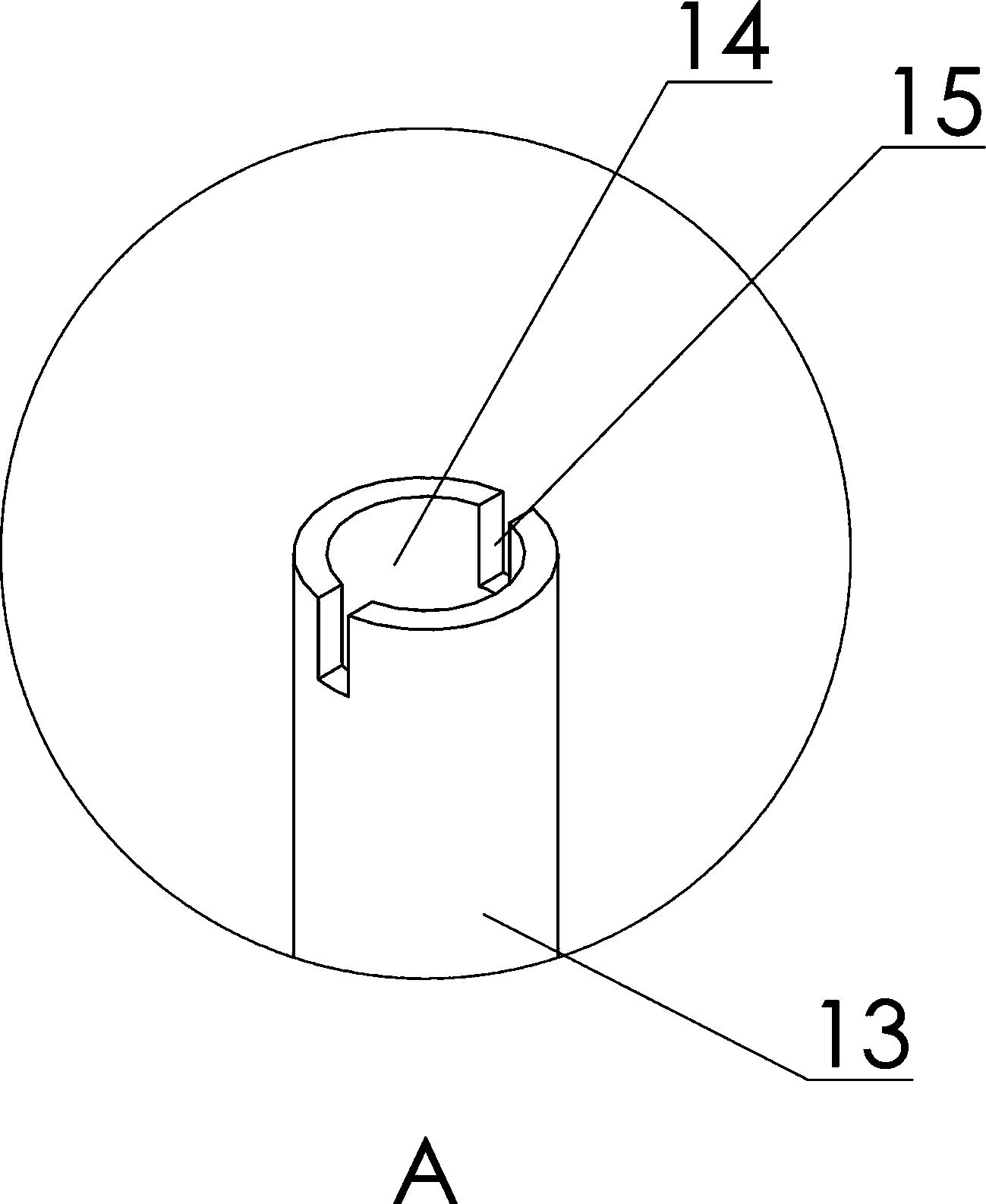

[0015] as attached Figure 1-3 As shown, the present invention consists of a lead clamping device and a remote operating lever; the lead clamping device includes a base 1, an L-shaped conjoined seat 2 arranged at the lower end of the base 1, and an upper The hook 3, the lower locking device inserted in the longitudinal through hole of the base 1, and the disguised transmission device inserted in the transverse through hole of the L-shaped conjoined seat 2; the lower locking device includes a longitudinal screw 7, arranged in the longitudinal The lower hook 4 at the upper end of the screw rod 7 and the longitudinal bevel gear 8 threadedly connected with the longitudinal screw rod 7, the lower end of the lower hook 4 is fixedly provided with a bearing seat 6, and the upper end of the longitudinal screw rod 7 is inserted into the bearing seat 6 In the shaft hole, the lower end of the longitudinal screw 7 is inserted into the longitudinal through hole of the base 1; the phase-chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com