Jujube dryer

A dryer and cabinet technology, applied in application, food processing, food science, etc., can solve problems such as poor adjustability, low production efficiency, and inability to adapt to working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

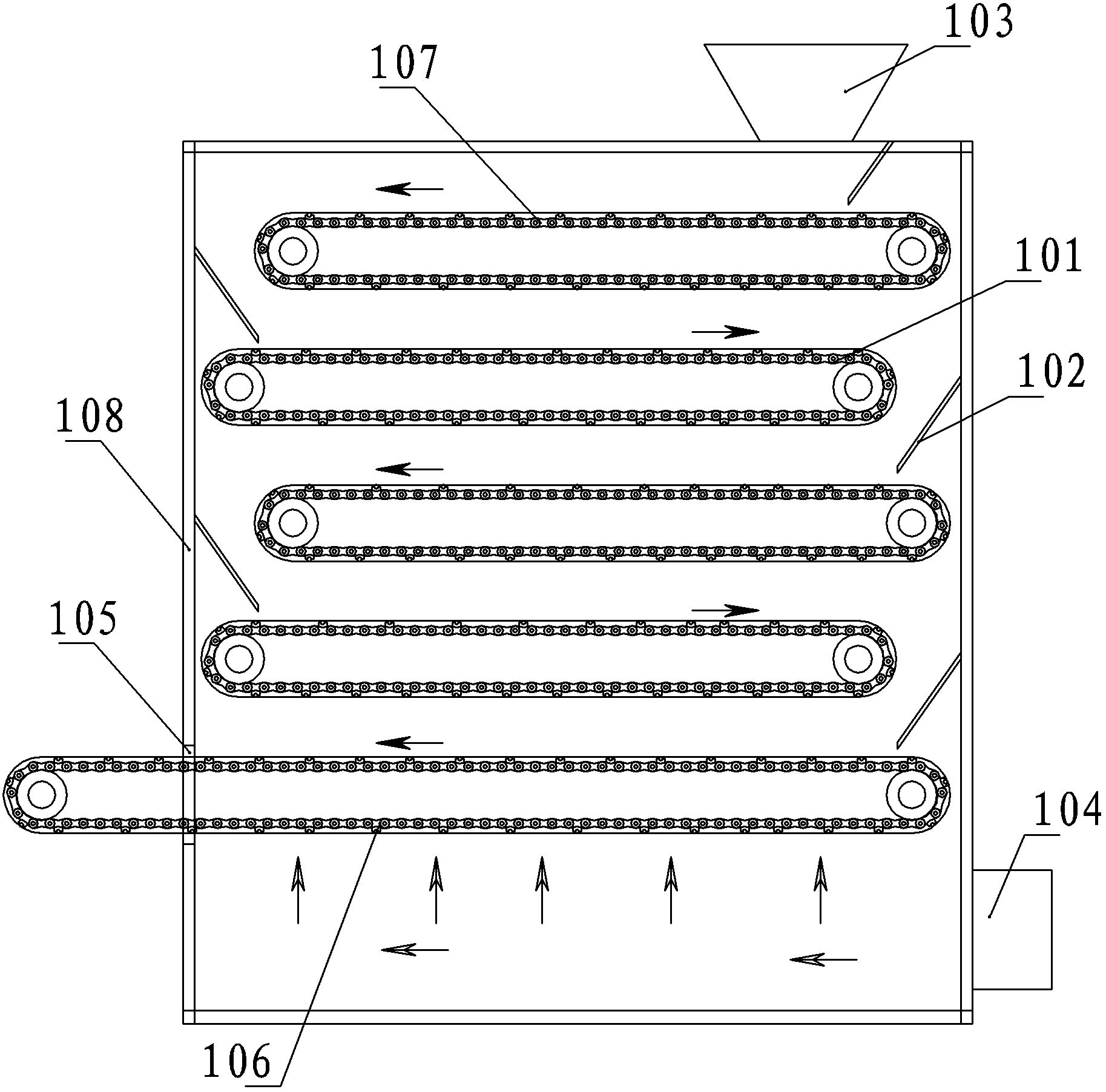

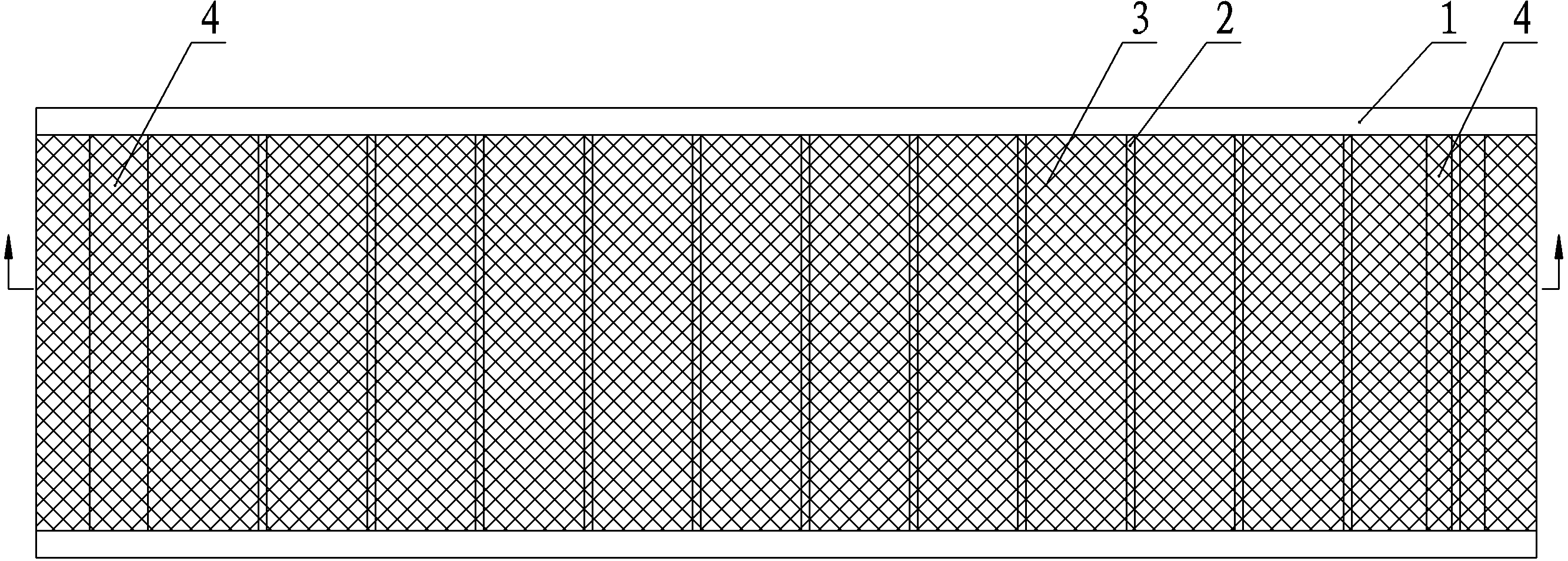

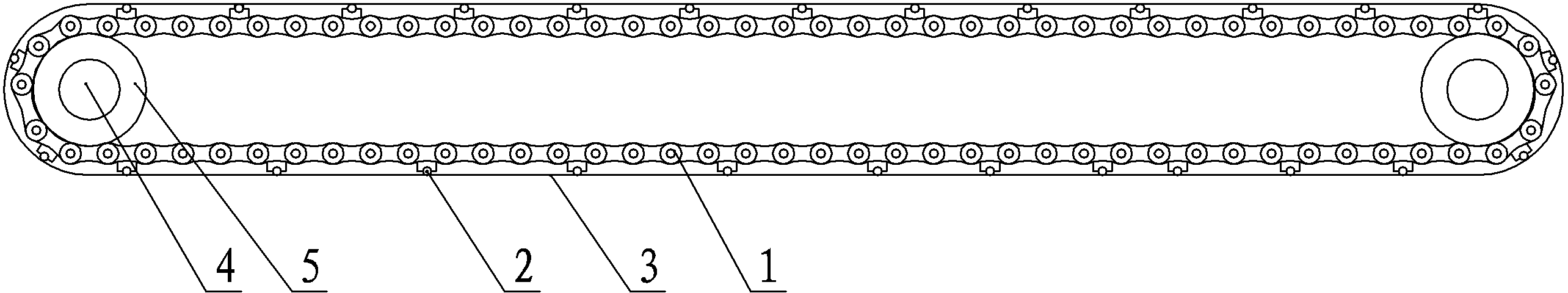

[0015] Example: see Figure 1-3 , a jujube dryer in the figure includes a box body, a feed port on the upper part of the box body, a material outlet port and an air inlet port on the lower part of the box body, and the box body is sequentially provided with several parallel arranged from top to bottom. For the tumbling screen, the moving directions of the adjacent tumbling screens are opposite, and a guide plate is arranged under the tail of each tumbling screen, and the lower edge of the guide plate is located at the upper part of the front end of the tumbling screen below it; the tumbling screen includes two sets of corresponding The two chains move synchronously, and the inner parts of the two chains are connected by several connecting rods. The tumbling screen also includes a screen connected to the outside of the connecting rod, and the screen and the shape of the chain always surround on the outside of all connecting rods. The feed port is located at the upper part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com