Three-dimensional ultrasonic imaging area array probe wiring method and three-dimensional ultrasonic imaging device

A technology of three-dimensional ultrasound and wiring method, which is applied in the directions of ultrasound/sonic wave/infrasonic wave diagnosis, acoustic wave diagnosis, infrasonic wave diagnosis, etc., to achieve the effect of improving electrical conductivity, simple operation, and good imaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

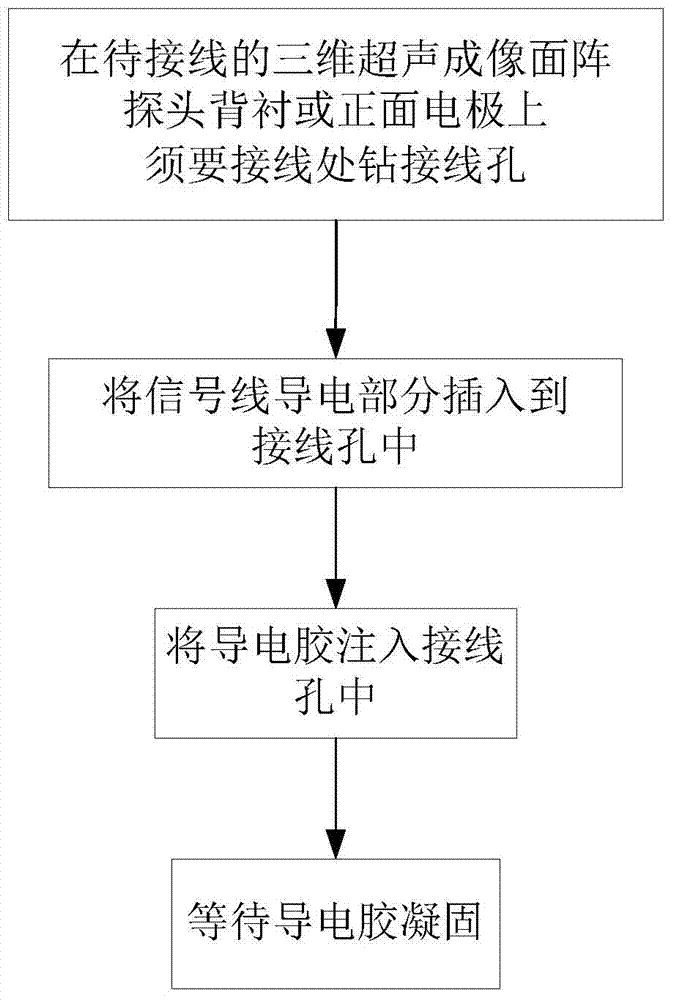

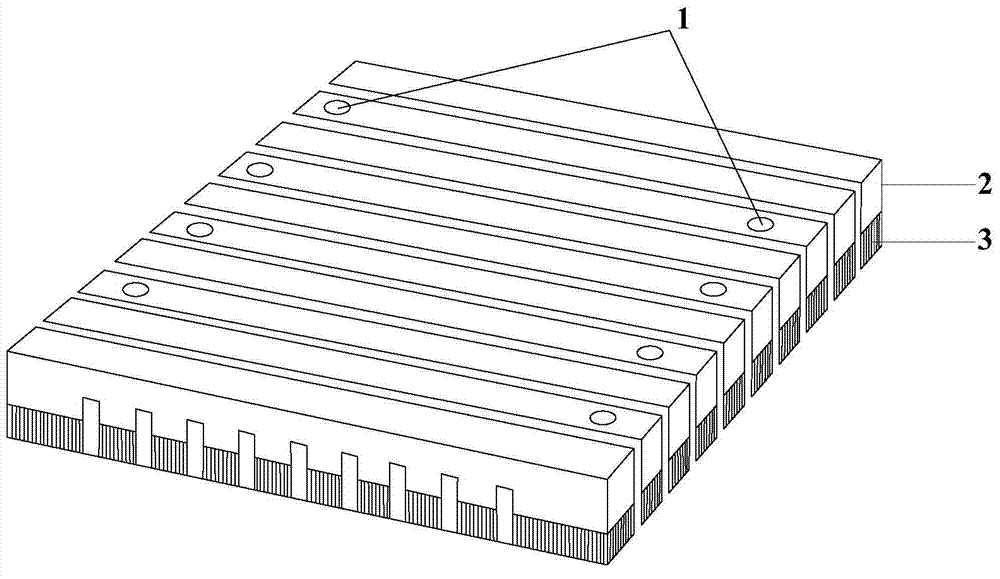

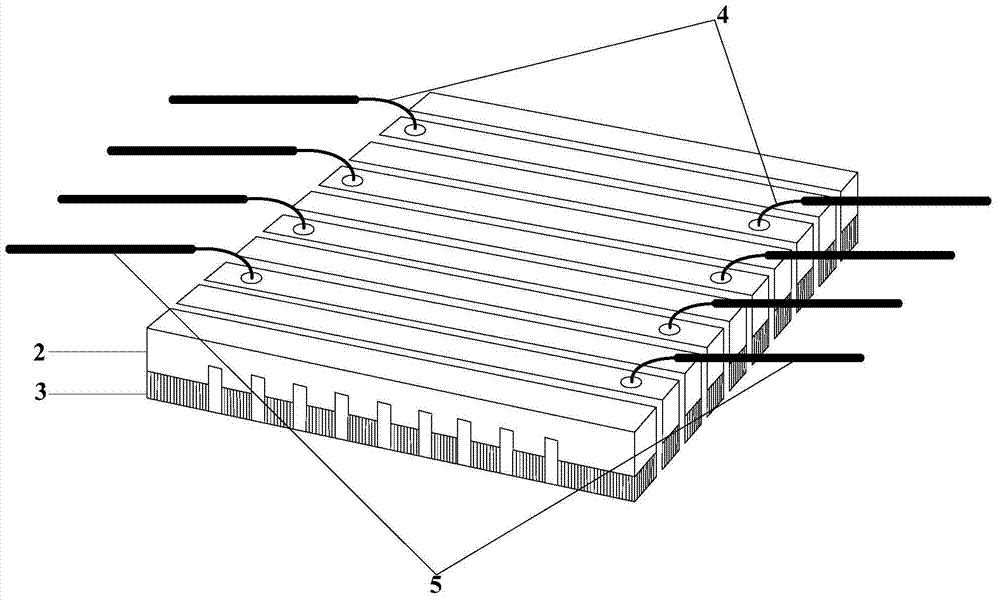

[0046] The backing of the three-dimensional ultrasonic imaging area array probe is cut into 8 columns by mechanical cutting, each column corresponds to 8 transducer units, the array width is about 120 microns, and the array spacing is about 45 microns. The material used is E-solder3022.

[0047] Under the microscope, use a thin wire needle with a diameter of about 80 microns to drill wiring holes at the required line of the backing array of the three-dimensional ultrasound imaging area array probe. In order to reduce the difficulty of wiring, the wiring holes are drilled at odd-even intervals. First, select 1, 3, and 5 odd-numbered columns to drill wiring holes on one side of the 3D ultrasound imaging area array probe backing array, and then select 2, 4, and 6 on the other side. Drill wiring holes in even rows. In this way, the drilled wiring holes are evenly distributed on both sides of the backing array of the three-dimensional ultrasonic imaging area array probe. Such as ...

Embodiment 2

[0052] The three-dimensional ultrasound imaging area probe is a front piezoelectric sheet (PZT) that is cut into an 8*8 matrix by mechanical cutting, with 8 transducer units in each row and column, and a total of 64 transducer units. The width of the transducer unit is about 120 microns, and the distance between the transducer units is about 45 microns. The electrodes covering the front array are gold electrodes, which are connected to the holes drilled in the front array by means of metal needles with a diameter of about 60 microns. .

[0053] Under a microscope, wiring holes are drilled in the piezo-electric (PZT) array using thin wire-type needles with a diameter of approximately 80 microns. In order to reduce the difficulty of wiring, the wiring holes are drilled at odd-even intervals. First, select 1, 3, and 5 odd-numbered columns to drill wiring holes on one side of the piezoelectric film (PZT) array, and then select 2, 4, and 6 even-numbered columns on the other side. ...

Embodiment 3

[0058] The wired three-dimensional ultrasound imaging area probe in embodiment 1 or embodiment 2 is connected with the corresponding conversion circuit and computer, and assembled into a three-dimensional ultrasound imaging device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com