A method for locating circular sand cores

A positioning method, a ring-shaped technology, applied in the direction of cores, casting molding equipment, casting molds, etc., can solve the problems of positioning table size changes, affecting the size of the box, and inaccurate positioning of sand cores, etc., to achieve accurate relative size, Easy to operate, easy to observe the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

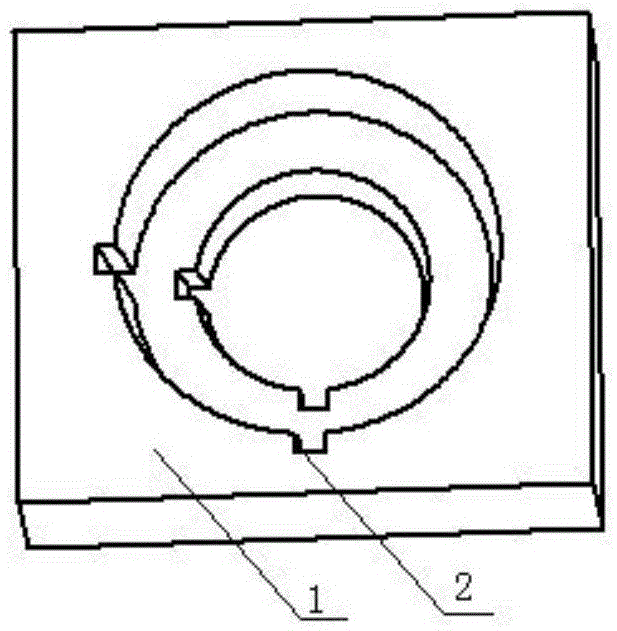

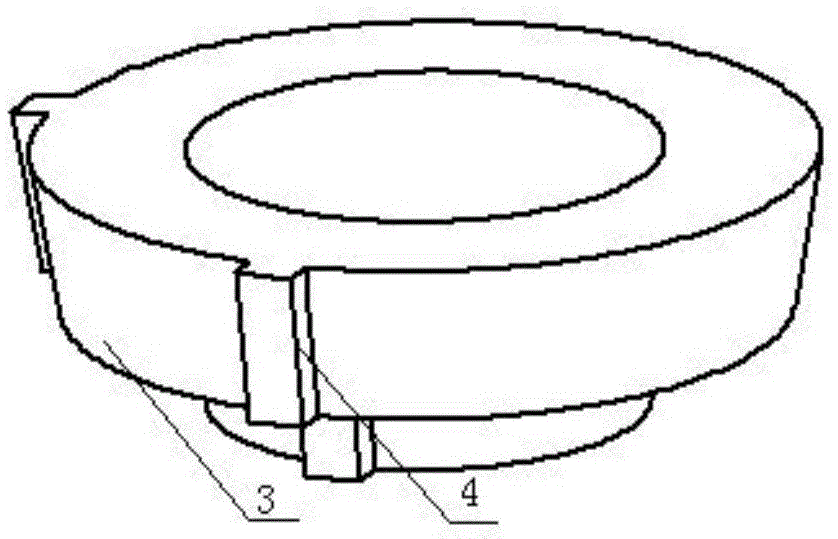

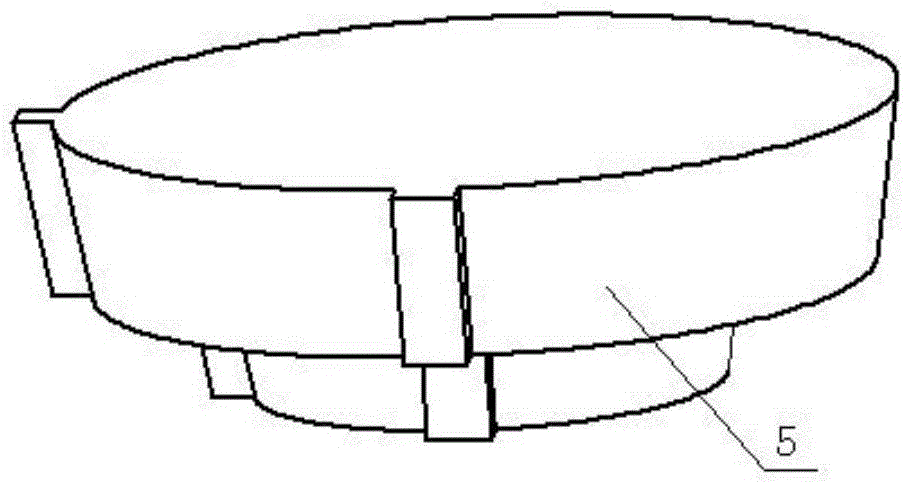

[0022] Such as figure 1 , 2 , as shown in 3:

[0023] A method for locating a circular sand core, the method comprising the steps of:

[0024] a. Place pattern 5 in the sand box, adjust the position, and flow molding sand into the sand box;

[0025] b. After the above-mentioned molding sand is hardened, the pattern 5 is proposed to form the cavity 1 and the positioning groove 2;

[0026] c, preparing the sand core 3 with the positioning table 4;

[0027] d. Make the sand core positioning platform 4 correspond to the positioning groove 2 in the cavity 1, and start core setting along the positioning groove 2. During the process, the operator can see the coordination between the positioning groove 2 and the positioning platform 4 throughout. Make sure the core is accurate.

[0028] e. The cross section of the positioning platform 4 is trapezoidal. The upper bottom of the trapezoid is 100mm long, the angle between the upper bottom and the two waists is 120°, the lower bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com