Frog rammer capable of being started and stopped rapidly

A technology of quick start and tamping machine, applied in the fields of soil protection, construction, infrastructure engineering, etc., can solve the problems of large energy loss, high risk, slow start of tamping machine, etc., and achieve the effect of quick start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

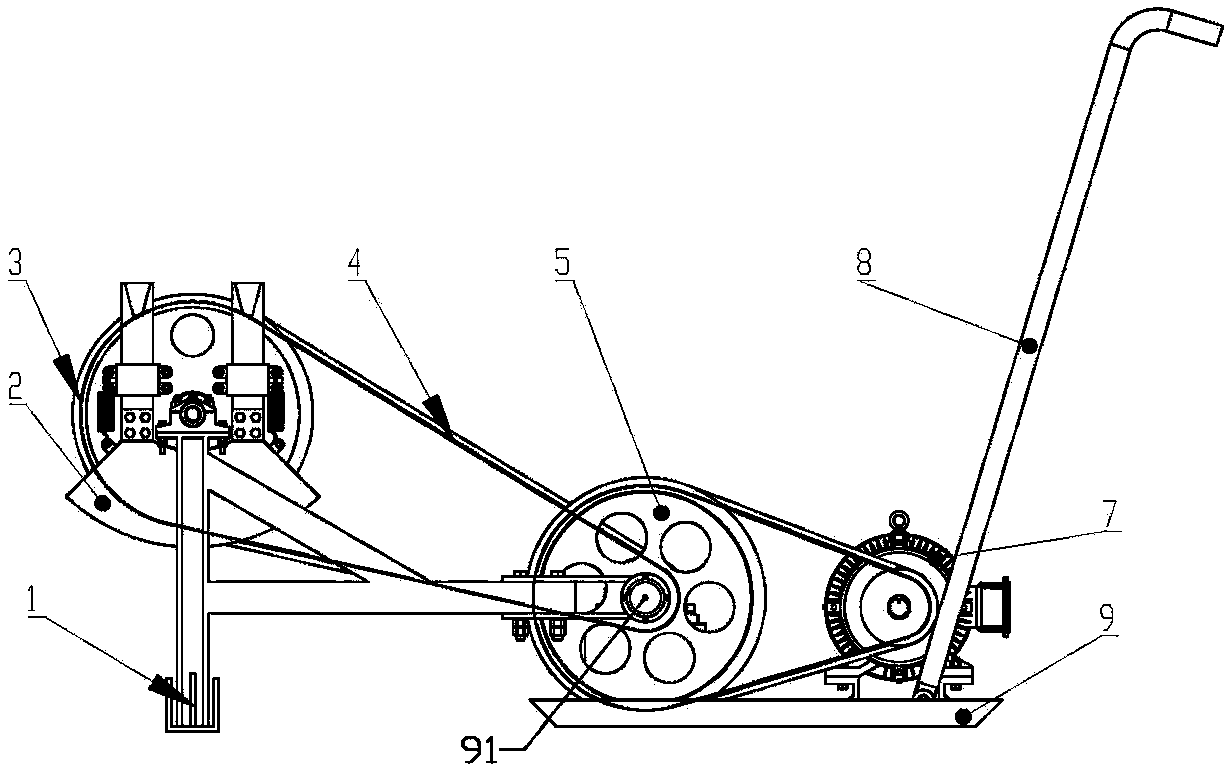

[0023] Embodiment one, such as Figure 1 to Figure 4 shown.

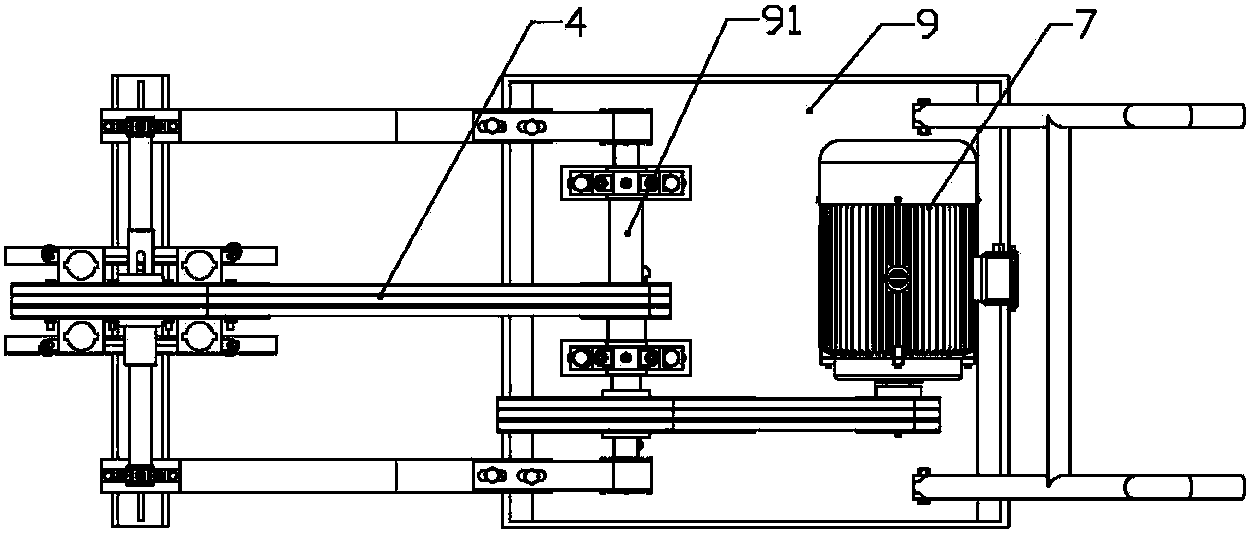

[0024] The quick-start frog-type rammer is mainly composed of a rammer 1, an eccentric block 2, a rammer pulley 3, a belt 4, a pulley 5 and a motor 7. Among them, the handrail 8 and the motor 7 are installed on the bottom plate 9, the bottom plate is a supporting part in contact with the ground, and is connected with the pulley 5 through a belt, and the pulley 5 is connected with the tamper pulley 3 through a belt, so as to realize driving the tamper pulley turn.

[0025] The rammer 1 and the base plate 9 are pivotally connected by a circular shaft 91, and the axis of the circular shaft 91 is coaxially arranged with the pulley, and the rammer pulley 3 is installed on the upper side of the rammer, all of which are prior art. The improvements are:

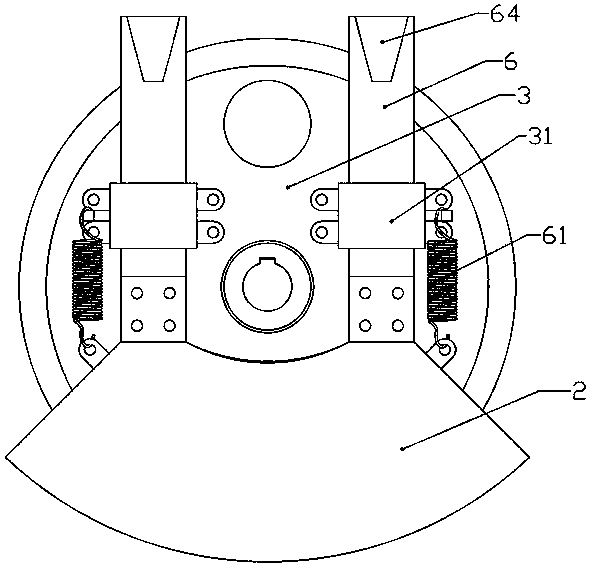

[0026] On the two sides of the tamper pulley 3 are respectively provided with two slideways symmetrically arranged with respect to the center of the tamper pulley and p...

Embodiment 2

[0030] Embodiment two, such as Figure 6 shown.

[0031] The difference from the first embodiment lies in the installation method and position of the elastic element. Specifically, the elastic element is a compression spring element 63 sleeved on the columnar part and located between the columnar part and the slideway, and a blocking piece 65 is fixed at the end of the columnar part by screws for replacement and maintenance. The spring element 63 compresses the eccentric block and is close to the axis of the rammer pulley.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com