Internal and external multiple-phase-change thermal insulation building block

A technology of thermal insulation blocks and phase change thermal insulation materials, applied in building materials and other directions, can solve the problems of small phase change enthalpy, high price of n-alkane, frost formation, etc., and achieve the effect of stable indoor temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and technical solutions.

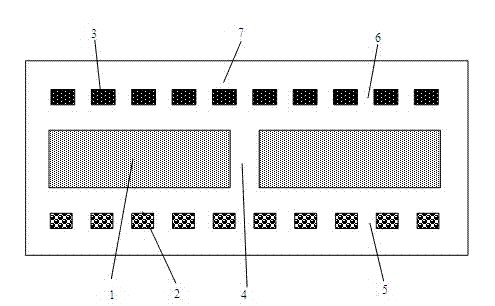

[0017] The internal and external multi-phase change thermal insulation blocks proposed by the present invention are as follows: figure 1 shown. It is mainly composed of an intermediate insulation layer 1, an external phase change layer 2, an internal phase change layer 3, an intermediate insulation layer rib 4, an external phase change layer rib 5, an internal phase change layer rib 6, and a block protection layer 7.

[0018] First, the concrete shell comprising the middle insulation layer rib 4, the outer phase change layer rib 5, the inner phase change layer rib 6 and the block protective layer 7 is made by a mold and includes the outer phase change layer 2 and the inner phase change layer 3. Bottom seal, curing for 15 days, pouring external phase change layer 2, internal phase change layer 3, and adding top seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com