Phase change energy storage composite concrete block and preparation method thereof

A concrete block and phase change energy storage technology, which is applied to building materials and other directions, can solve the problems of large volume of phase change energy storage concrete, easy leakage of phase change materials, poor working time efficiency, etc., and achieves stable indoor temperature, cheap raw materials, Density improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

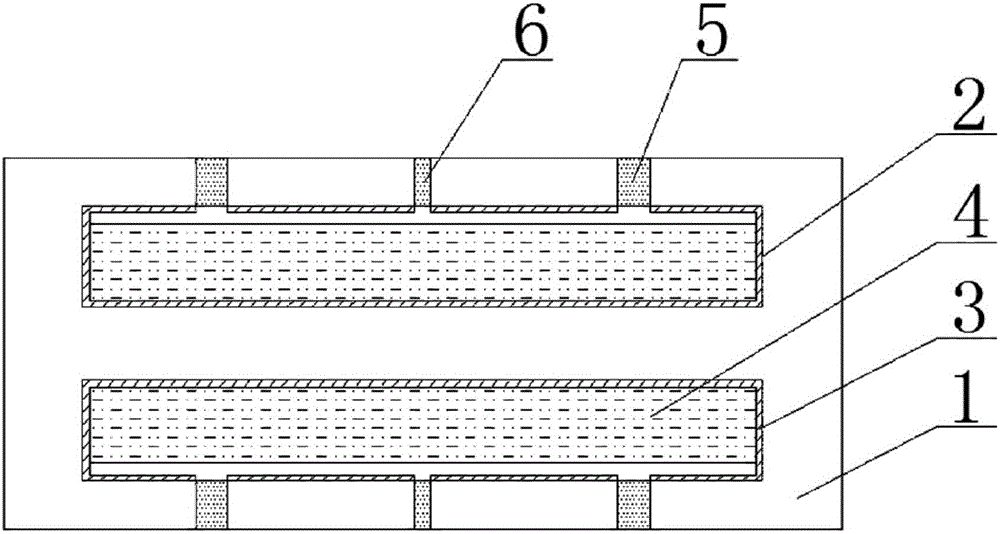

[0035] A phase-change energy storage composite concrete block, comprising a concrete matrix 1; two cavities 2 are symmetrically arranged inside the concrete matrix 1, and the inner walls of the cavities 2 are covered with a phase-change coating 3, and the cavities 2 is filled with a phase change material layer 4, and two feed ports 5 and one air outlet 6 are provided between the concrete matrix 1 and the cavity 2;

[0036] The volume of the phase change material layer 4 is 60% of the volume of the cavity 2 .

[0037] The concrete matrix 1 is made of the following raw materials in parts by weight: 3.0 parts of cement, 10.0 parts of iron lumps, 3.0 parts of iron filings, 0.5 parts of steel fibers, 0.05 parts of water reducing agent and 1 part of water;

[0038] The feed inlet 5 and the air outlet 6 are made of the following raw materials in parts by weight: 4.0 parts of cement, 2.0 parts of iron filings, 0.5 parts of phenolic resin glue, 0.2 parts of water reducing agent and 1 p...

Embodiment 2

[0053] A phase-change energy storage composite concrete block, comprising a concrete matrix 1; two cavities 2 are symmetrically arranged inside the concrete matrix 1, and the inner walls of the cavities 2 are covered with a phase-change coating 3, and the cavities 2 is filled with a phase change material layer 4, and two feed ports 5 and one air outlet 6 are provided between the concrete matrix 1 and the cavity 2;

[0054] The volume of the phase change material layer 4 is 75% of the volume of the cavity 2 .

[0055] The concrete matrix 1 is made of the following raw materials in parts by weight: 2.0 parts of cement, 8.0 parts of iron block, 8.0 parts of iron filings, 1.0 part of steel fiber, 0.1 part of water reducing agent and 1 part of water;

[0056] The feed inlet 5 and the air outlet 6 are made of the following raw materials in parts by weight: 3.0 parts of cement, 3.0 parts of iron filings, 0.8 parts of phenolic resin glue, 0.1 part of water reducing agent and 1 part of...

Embodiment 3

[0071] A phase-change energy storage composite concrete block, comprising a concrete matrix 1; two cavities 2 are symmetrically arranged inside the concrete matrix 1, and the inner walls of the cavities 2 are covered with a phase-change coating 3, and the cavities 2 is filled with a phase change material layer 4, and two feed ports 5 and one air outlet 6 are provided between the concrete matrix 1 and the cavity 2;

[0072] The volume of the phase change material layer 4 is 90% of the volume of the cavity 2 .

[0073] The concrete matrix 1 is made of the following raw materials in parts by weight: 1.5 parts of cement, 6.0 parts of iron lumps, 8.0 parts of iron filings, 1.5 parts of steel fibers, 0.15 parts of water reducing agent and 1 part of water;

[0074] The feed inlet 5 and the air outlet 6 are made of the following raw materials in parts by weight: 2.0 parts of cement, 4.0 parts of iron filings, 1.0 part of phenolic resin glue, 0.05 part of water reducer and 1 part of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com