Ultralow temperature processing method and ultralow temperature processing device for liquefied natural gas (LNG) equipment

A liquefied natural gas and ultra-low temperature technology, which is used in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of short service life and failure of equipment, and achieve the effect of improving service life and avoiding wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

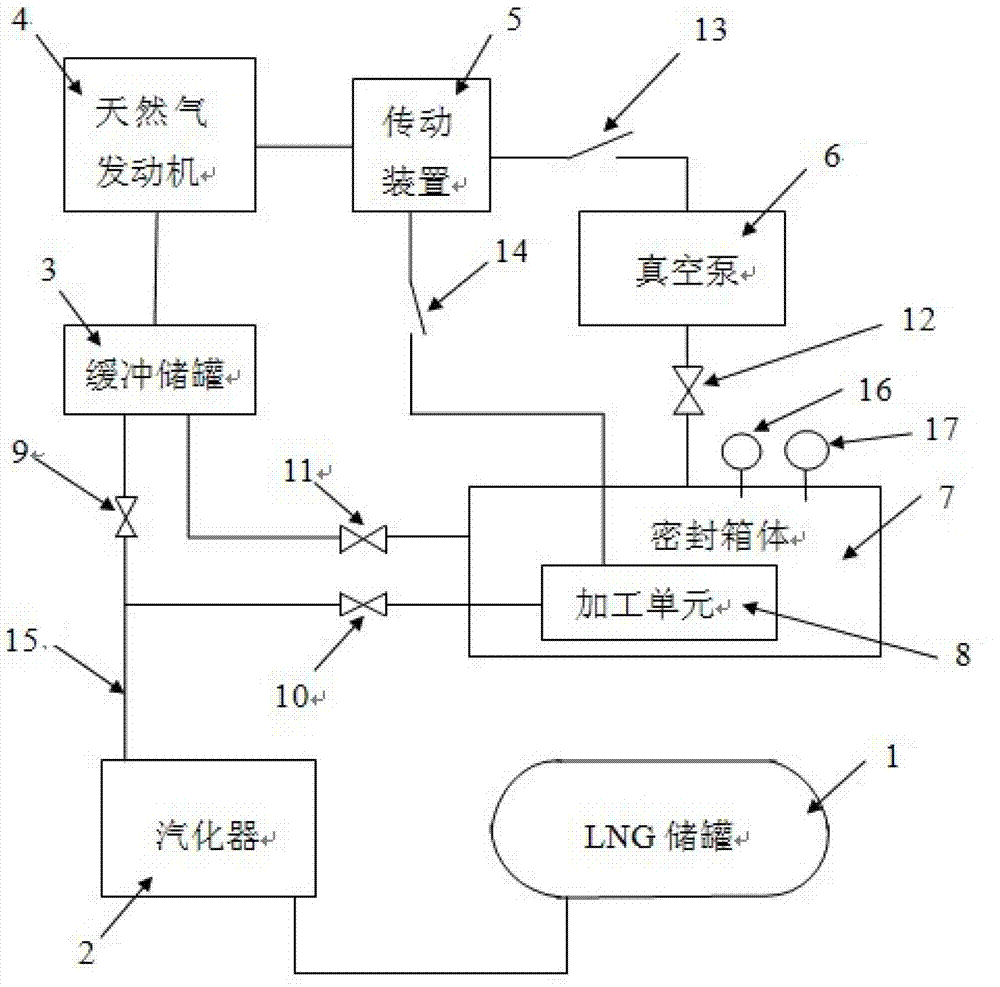

[0023] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] A device for ultra-low temperature processing of liquefied natural gas, the structure of which is shown in Figure 1:. Composed of LNG storage tank 1, vaporizer 2, buffer storage tank 3, natural gas engine 4, transmission device 5, vacuum pump 6, sealed box 7, processing unit 8, insulation pipeline 15, shut-off valve a9, shut-off valve b10, shut-off valve c11, cut-off valve d12, connection switch e13, connection switch f14, pressure gauge 16 and safety valve 17. The buffer storage tank 3 is installed between the carburetor 2 and the natural gas engine 4, the processing unit 8 is in the sealed box 7, one end of the transmission device 5 is connected to the natural gas engine 4, and the other end is connected to the processing unit 8 One end of the vacuum pump 6 is connected to the transmission 5, and one end is connected to the sealed bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com