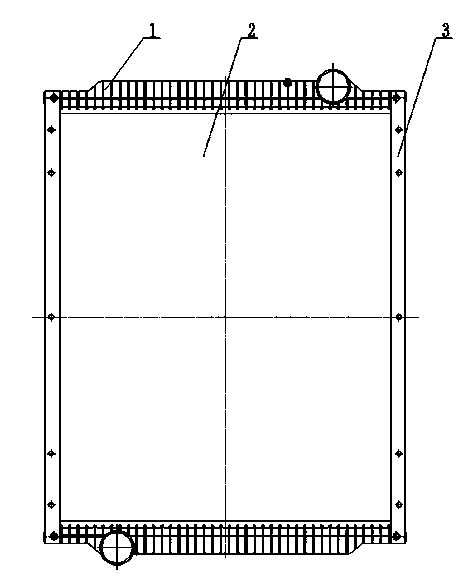

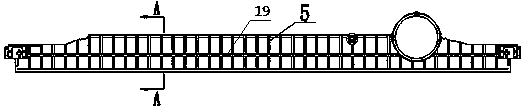

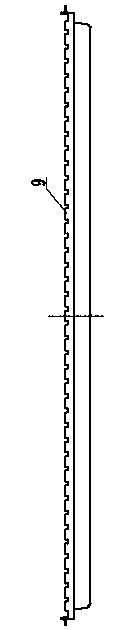

Automobile radiator with reinforced water chamber structure

An automotive radiator, reinforced technology, applied in the direction of machine/engine, engine cooling, engine components, etc., can solve the problems of low pressure on the radiator, the automobile radiator can not meet its requirements, etc., to achieve high pressure, structural Simple, good anti-vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] Figure 8 It is a schematic diagram of the separator structure of the present invention. The separator 7 is made of stainless steel. The upper surface of the separator 7 has a plurality of upwardly turned installation claws 16 on both sides. Inside the slot 6, there are a plurality of support plates 17 turned downwards on both sides of the lower surface of the partition plate 7 . There are a plurality of through holes 8 at a certain interval on the partition 7, Figure 9 It is the first embodiment of the separator of the present invention, the through hole 8 is a circular hole; Figure 10 As the second embodiment of the separator of the present invention, the through hole may be a square hole 20; Figure 11 As the third embodiment of the separator of the present invention, the through holes may be elongated holes 21 . The circular holes and square holes are arranged in two rows, and the long holes are arranged in a single row. The area of the through holes accounts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com