Automatic test equipment for mobile terminal functional testing

A technology of automatic testing equipment and mobile terminals, which is applied in branch equipment, telephone communication, electrical components, etc., can solve the problems of high misjudgment rate, fuzzy judgment standards, easy to be approved and returned, and achieve the effect of automation and efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

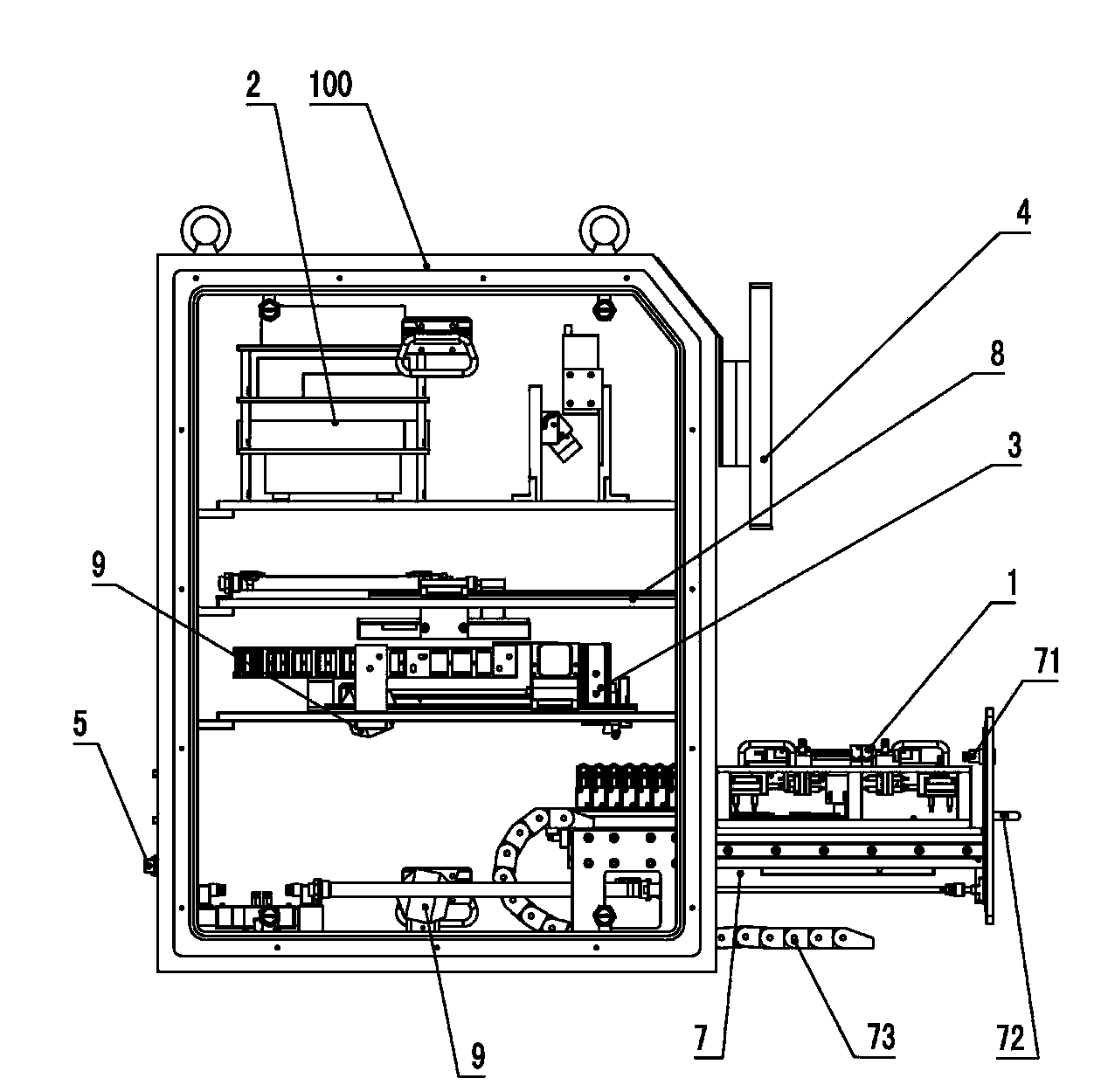

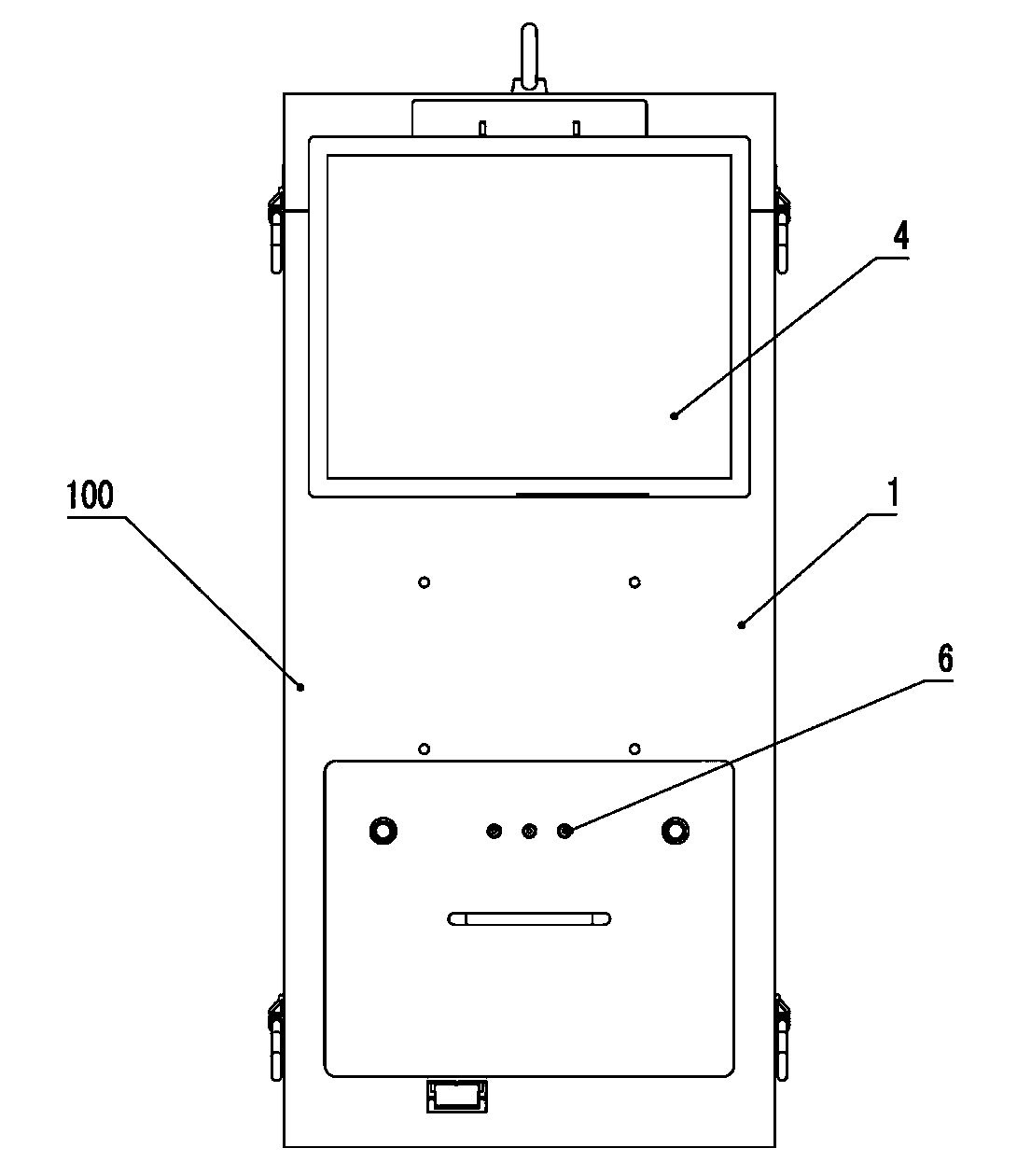

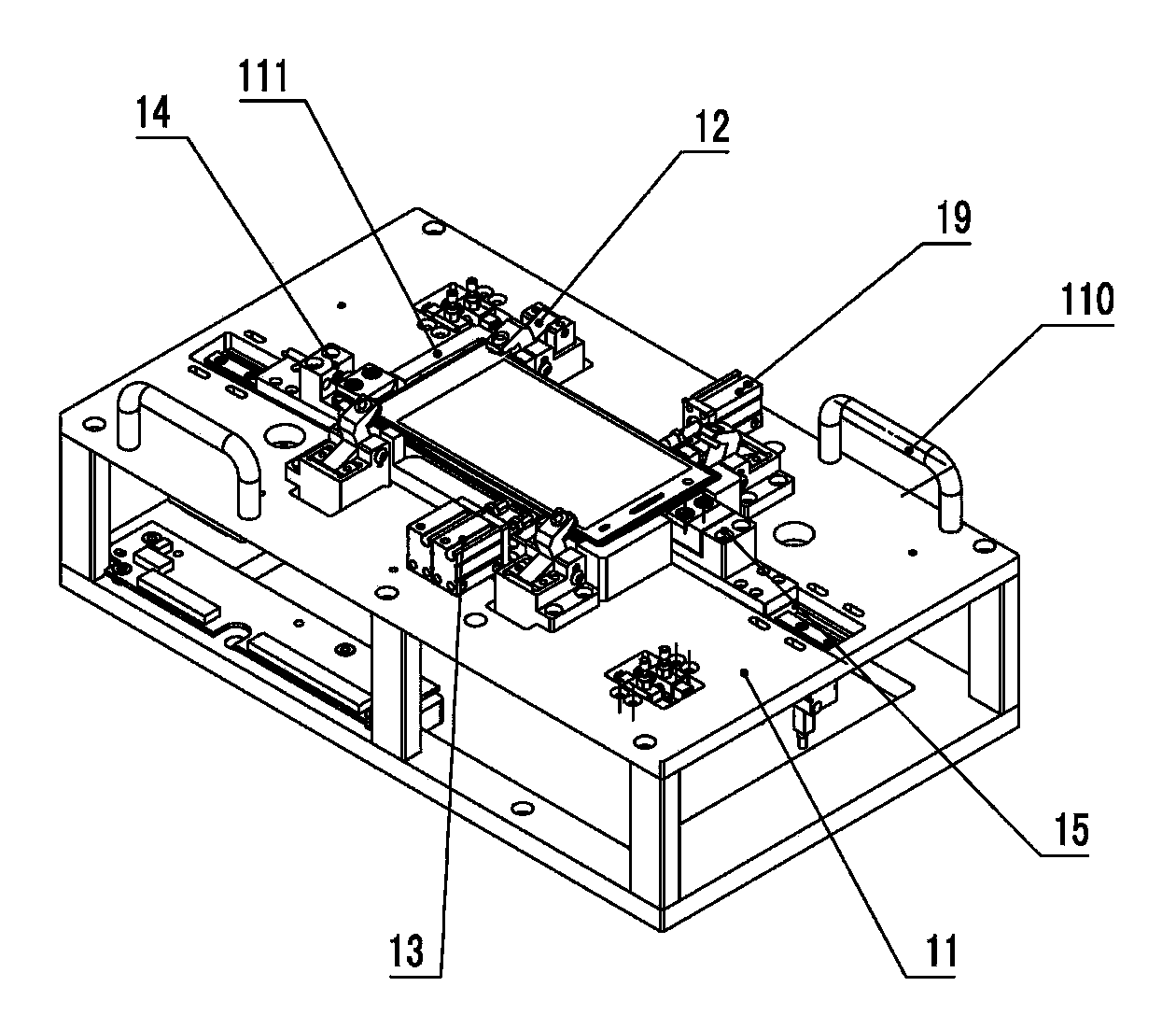

[0041] Figure 1 to Figure 13The reference numerals in the figure are: test box 100; mobile terminal 200; test fixture 1; fixture support 11; gripper mechanism 12; volume plus and minus key test mechanism 13; Mechanism 15; shock sensor 16; position sensor 17; free-field microphone 18; camera key testing mechanism 19; fixture handle 110; mobile terminal fixing seat 111; Audio acquisition card 24; audio switch box 25; Ethernet switch 26; camera power supply 27; visual audio test support 28; finger touch test mechanism 3; drag chain 31; Feeding mechanism 34; pressure field microphone 35; Y-axis stepping motor 36; light avoidance through hole 37; finger touch test support 38; Z-axis feeding mechanism 39; display 4; interface board 5; indicator light 6; drawer access Mechanism 7; switch button 71; drawer handle 72; drag chain 73; solenoid valve 74...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com