Electret sheet

An electret, multifunctional monomer technology, applied in the direction of electret, electret electrostatic transducer, variable capacitor, etc., can solve problems such as complex procedures, achieve excellent piezoelectricity, improve piezoelectricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8、 comparative example 1~3

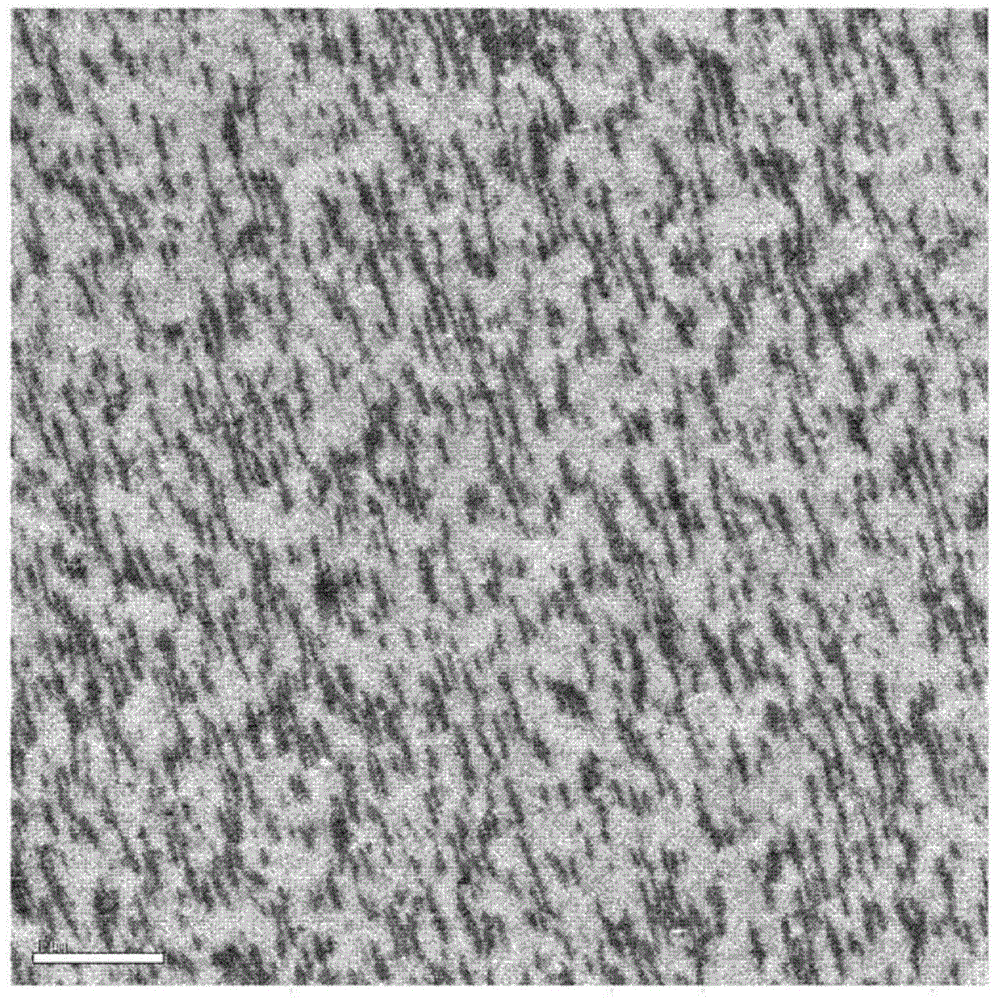

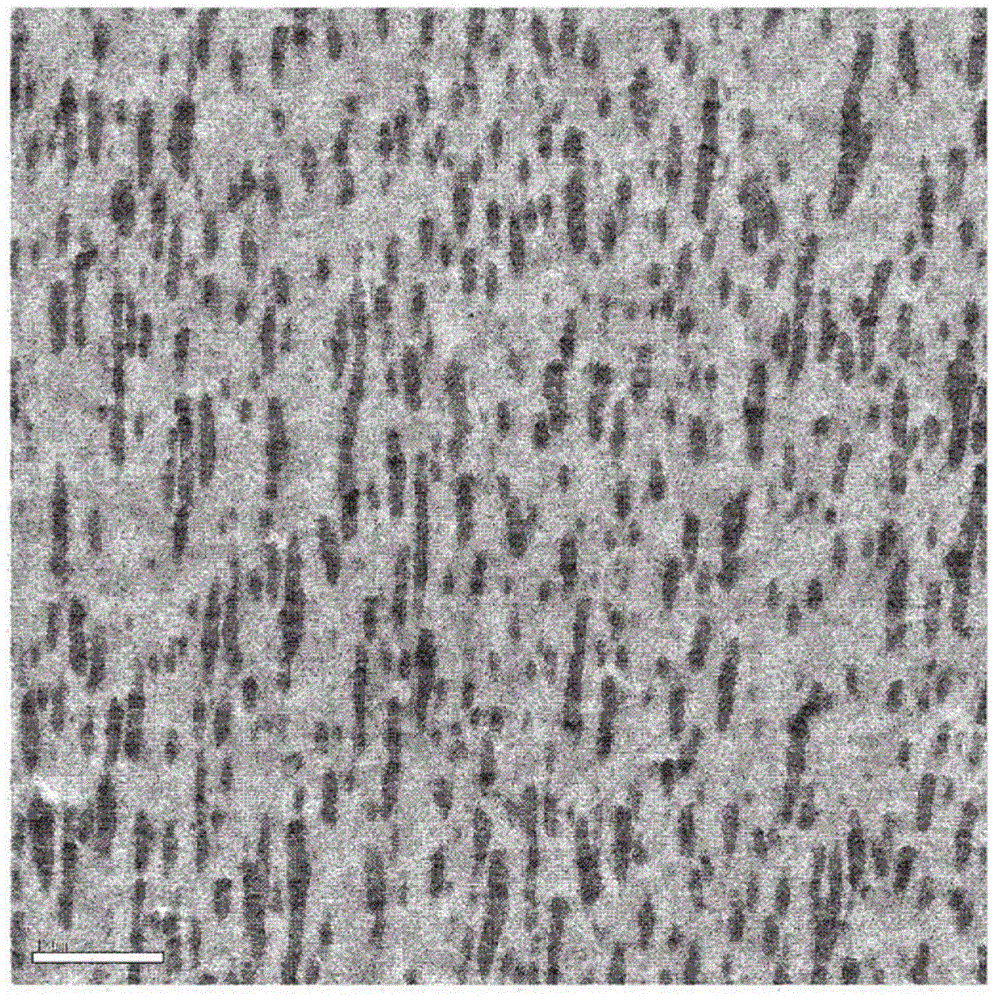

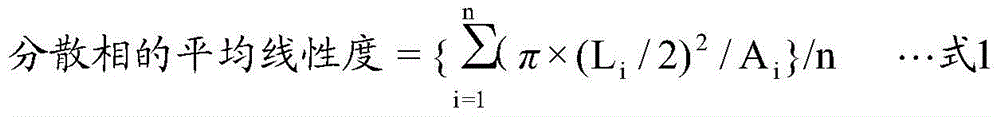

[0088] Using a twin-screw extruder whose barrel temperature was adjusted to 170° C., the following synthetic resin composition was fully melt-kneaded, and extruded from a T-die to obtain a foamable resin sheet with a thickness of 0.3 mm. The synthetic resin composition is composed of a predetermined amount of homopolypropylene A (manufactured by Nippon Polypropylene Co., Ltd., trade name "NovatecPP EA9") shown in Table 1 or Table 2, flexural modulus of elasticity: 1800 MPa, melt flow rate (MFR): 0.5 g / 10 minutes), homopolypropylene B (manufactured by Japan Polypropylene Co., Ltd., trade name "NovatecPP EA8W", flexural modulus of elasticity: 1500MPa, melt flow rate: 0.8g / 10 minutes), homopolypropylene C (Nippon Polypropylene Propylene Co., Ltd., trade name "NovatecPP EG8", flexural modulus: 950 MPa, melt flow rate: 0.8 g / 10 minutes), linear low-density polyethylene (Prime Polymer Co., Ltd., trade name "Moretec0138N", density : 0.917kg / m 3 , melt flow rate: 1.3g / 10 minutes), tr...

Embodiment 9

[0091] (Example 9, Comparative Example 4)

[0092] Using a twin-screw extruder whose cylinder temperature is adjusted to 170°C, the following synthetic resin composition is fully melt-kneaded and extruded from a T-die to obtain a thickness of 0.3mm and an apparent density of 0.9g / cm 3The synthetic resin non-foaming sheet of synthetic resin, described synthetic resin composition is made of homopolypropylene A (manufactured by Nippon Polypropylene Co., Ltd., trade name "NovatecPP EA9") of the specified amount shown in Table 1 or Table 2, flexural modulus of elasticity: 1800MPa , melt flow rate (MFR): 0.5g / 10 minutes), linear low-density polyethylene (manufactured by Prime Polymer, trade name "Moretec0138N", density: 0.917kg / m 3 , melt flow rate: 1.3g / 10 minutes), trimethylolpropane trimethacrylate (TMPT) and glass spheres (manufactured by Sumitomo 3M Co., Ltd., trade name "Glass Bubble S60HS", average particle size: 50 μm, true Density (particle density): 0.6g / cm 3 )constitute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com