Method for manufacturing bonded gloves without sewing threads

A production method and bonding technology, applied to gloves, clothing, clothing, etc., to achieve the effect of improving quality, improving protection, and reducing the learning curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

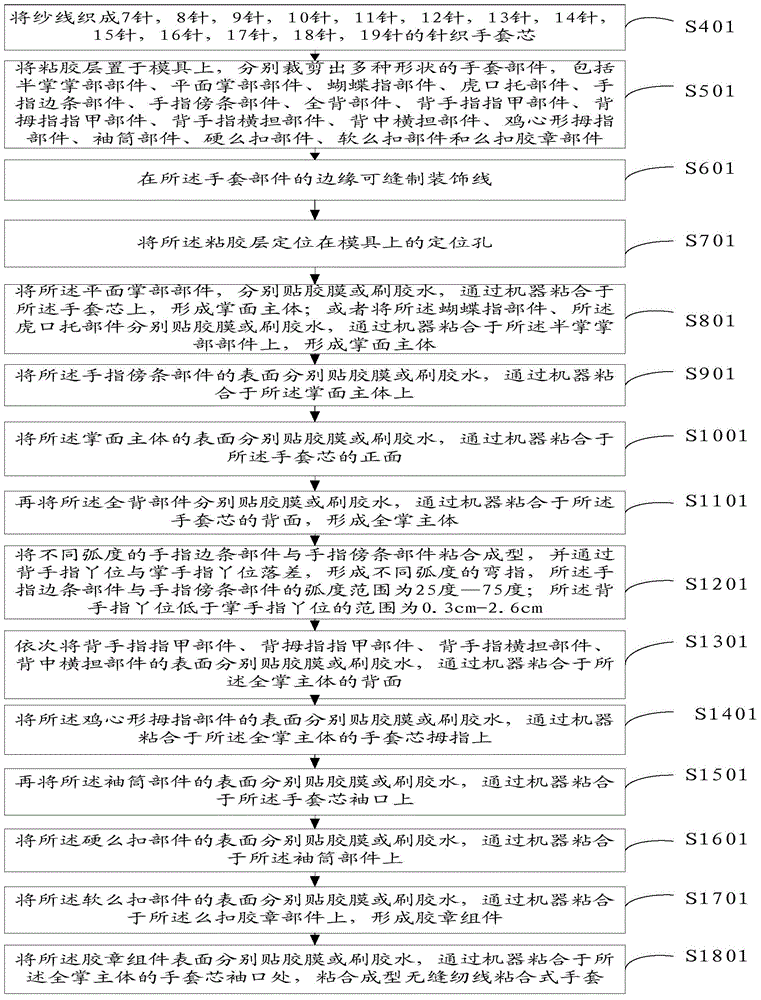

[0054] see figure 1 , ( figure 1 shows the flow chart of the manufacturing method), the embodiment of the present invention provides a method for manufacturing non-sewing thread adhesive gloves, including the following steps:

[0055] Step S401, knitting the yarn into a knitted glove core with 7 stitches, 8 stitches, 9 stitches, 10 stitches, 11 stitches, 12 stitches, 13 stitches, 14 stitches, 15 stitches, 16 stitches, 17 stitches, 18 stitches, and 19 stitches ;

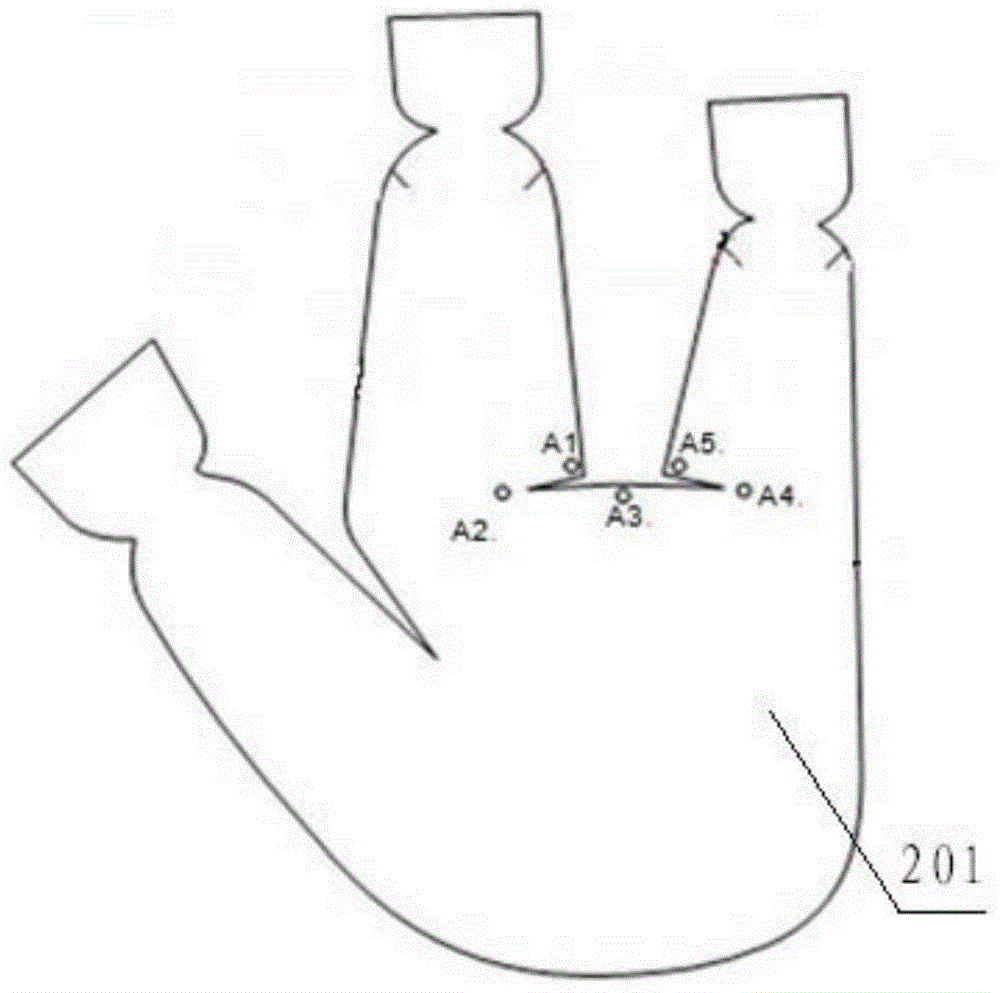

[0056] Step S501, place the adhesive layer on the mold, and cut out various shapes of glove parts, including half-palm parts, flat palm parts, butterfly finger parts, tiger mouth support parts, finger edge parts, and finger strips parts, full back part, back fingernail part, back thumbnail part, back finger arm part, back center arm part, chicken heart ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com