A rotary bottle washing machine driven by full servo control

A servo-controlled, rotary technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., to meet the requirements of the industry, simplify the mechanical transmission structure, and reduce the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

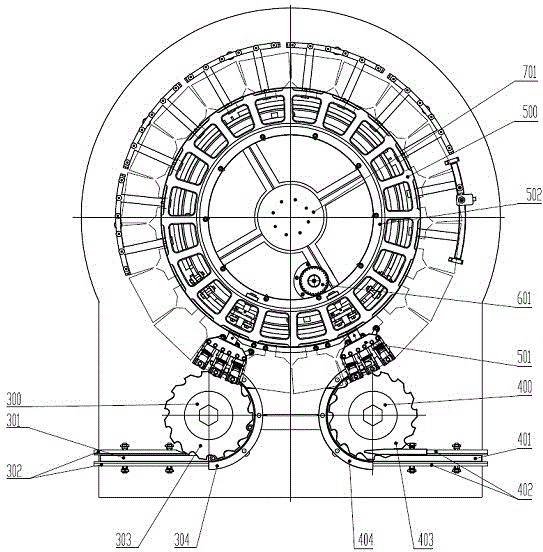

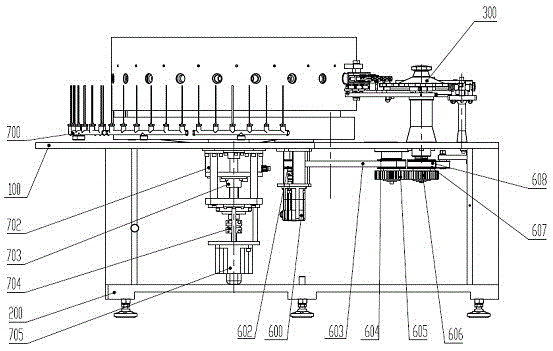

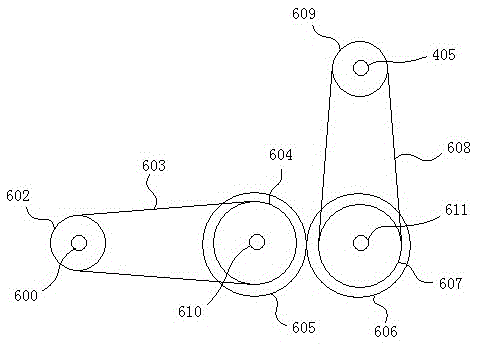

[0013] see figure 1 —— image 3 , a rotary bottle washing machine driven by full servo control, including a frame, the frame has a workbench 100, the bottom of the workbench 100 is provided with an installation base plate 200, and there is a mechanism installation space between the workbench 100 and the installation base plate 200; the workbench 100 There is a ring bottle clamping rotary mechanism 500 on the top of the bottle clamping rotary mechanism 500. A circle of chucks 501 is provided on the clamping bottle rotary mechanism 500. The side of the workbench 100 is provided with a bottle input dial mechanism 300 and a bottle output dial mechanism 400. The bottle clamping rotary mechanism 500 is equipped with a circular reciprocating tracking and needle frame mechanism 700 equipped with several water spray pipes; the bottle-feeding dial mechanism 300 is connected with the bottle-feeding dial 303 and the dialing wheel fence 304 by the bottle-feeding track 301 and the fences 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com