Device for machining valve seat valve port of cylinder head of diesel engine

A cylinder head and valve seat technology, which is applied in the field of processing diesel engine cylinder head valve seat valves, can solve the problems of affecting the flatness of valve ports, difficult adjustment, low production efficiency, etc., and achieves improved production efficiency and high cost performance , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

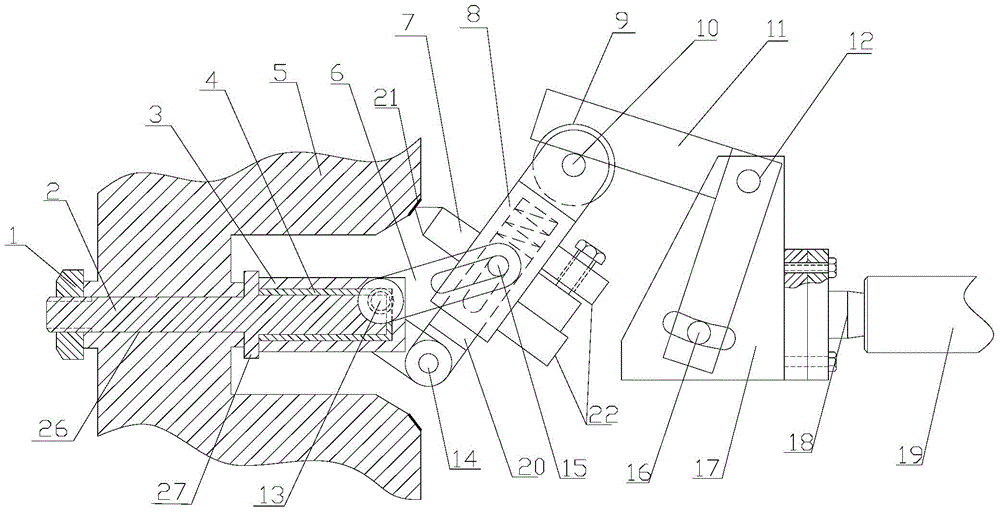

[0032] Attached below Figure 1-16 An embodiment of the present invention is described.

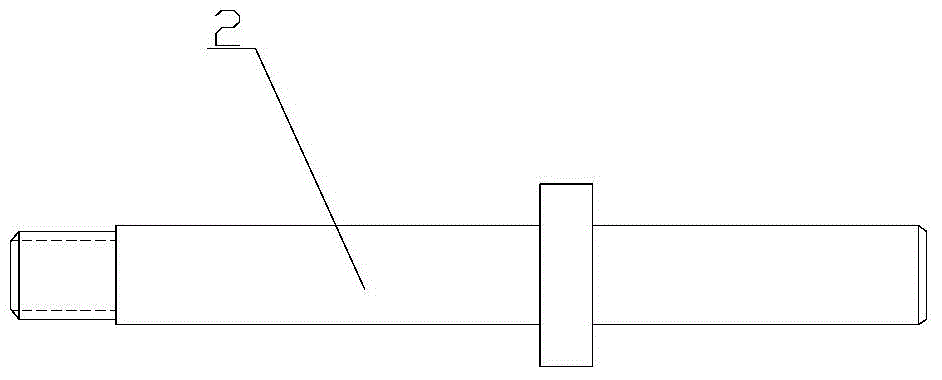

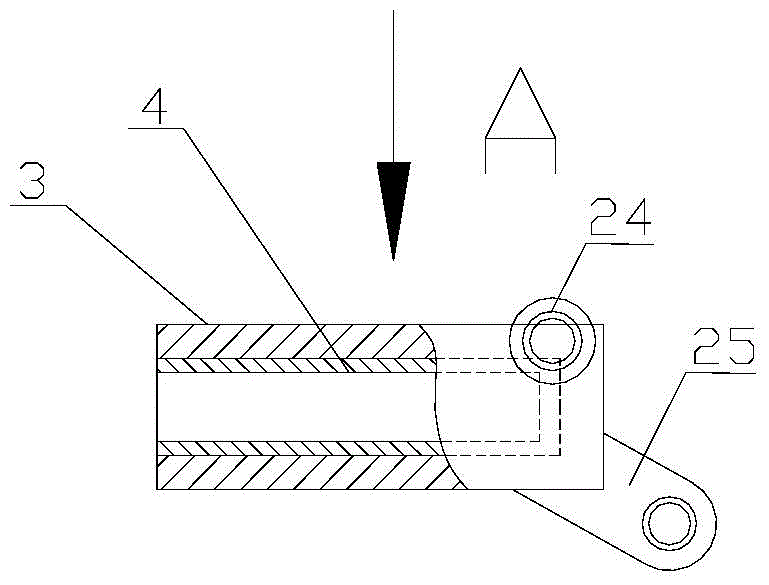

[0033] A device for processing a valve seat valve port of a cylinder head of a diesel engine has a core shaft I2, a shaft sleeve 3, a connecting rod 6, a core shaft II20, a movable support sleeve 8, a transmission rod 11, a support plate 17 and a connecting shaft 18. The core The shaft I2 is sleeved in the valve stem hole 26 of the cylinder head 5 and one side of the shaft shoulder 27 on the core shaft I2 is pressed against the inner wall of the cylinder head 5, and the other side of the shaft shoulder 27 is pressed against the sliding bearing 4 and the core shaft I2. The shaft sleeve 3, the other end of the mandrel I2 is locked with the nut 1; the end of the shaft sleeve 3 is formed with a connecting lug 25 and a connecting column 24 at 90 degrees. One end of the connecting rod 6 is fixedly connected with the connecting column 24, and the mandrel One end of II20 is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com