Method for predicting welding deformation of large radar structural part

A technology of large-scale structural parts and welding deformation, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of high cost, reduce the number of manufacturing, shorten the simulation time, and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment, the present invention will be further described.

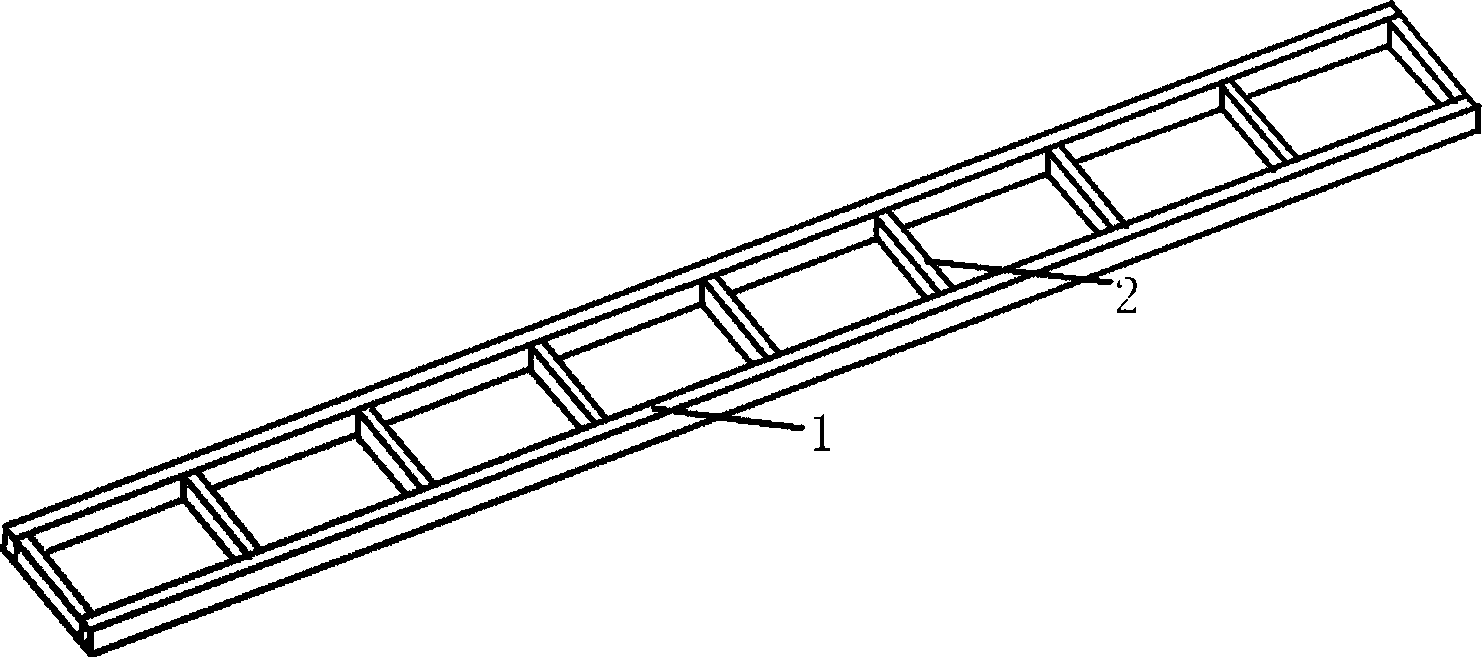

[0026] see figure 1 , the large-scale radar structure consists of two parallel longitudinal beams 1, and several beams 2 between the two longitudinal beams 1, forming a rectangular frame shape by welding, wherein the length of the longitudinal beam 1 is 8000mm, and the length of the beam 2 is 1000mm; The longitudinal beam 1 has a rectangular cross-section and is formed by two U-shaped steels welded oppositely; the material of the U-shaped steels is Domex high-strength steel with a thickness of 3 mm.

[0027] The specific operation steps for predicting the welding deformation of the above-mentioned large-scale radar structural parts are as follows:

[0028] 1) Determine the MIG welding parameters of large radar structural parts, mainly including: the material of the parts to be welded is high-strength steel, the thickness of the parts to be welded is 3mm, the joint form is butt join...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com