Clamp holder for pipe screwing machine

A gripper and pipe twisting machine technology, which is applied to workpiece clamping devices, drill pipes, casings, etc., can solve the problems of reducing work efficiency, affecting processing effect, and poor clamping effect, and achieving high work efficiency and processing. Good effect and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

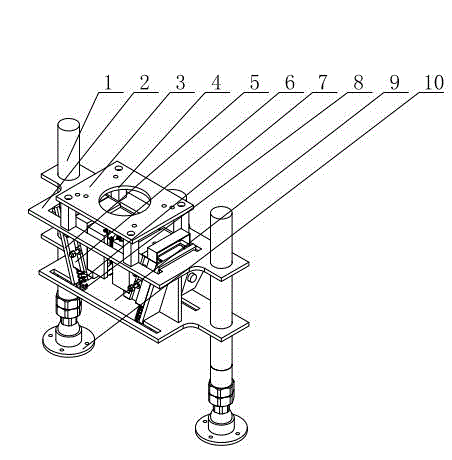

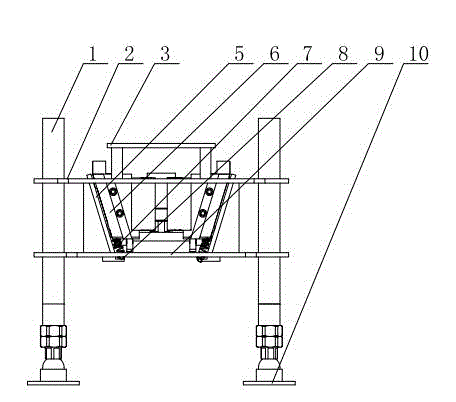

[0017] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 and figure 2 As shown, the clamper for the pipe twisting machine of this embodiment includes bases 10 arranged at intervals, on which brackets 1 are fixed in the vertical direction by fasteners, and two brackets 1 are installed with upper and lower intervals. The first support plate 2 and the second support plate 9, between the first support plate 2 and the second support plate 9 are fixed with a relatively inclined fixed plate 5, the diameter of a pair of fixed plates 5 decreases sequentially from top to bottom, Slips 6 are respectively installed on the inside of the fixed plate 5, and a fixed seat 8 is installed on the bottom of the second support plate 9, and a spring 7 is installed between the fixed seat 8 and the bottom of the slips 6; The support frame is equipped with a top plate 3, and the middle part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com