Inkjet printing device and method for coating alignment film

A technology of inkjet printing and alignment film, applied in printing and other directions, can solve the problems of uneven coating and slow diffusion of alignment film, and achieve the effect of accelerating diffusion and solving uneven diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

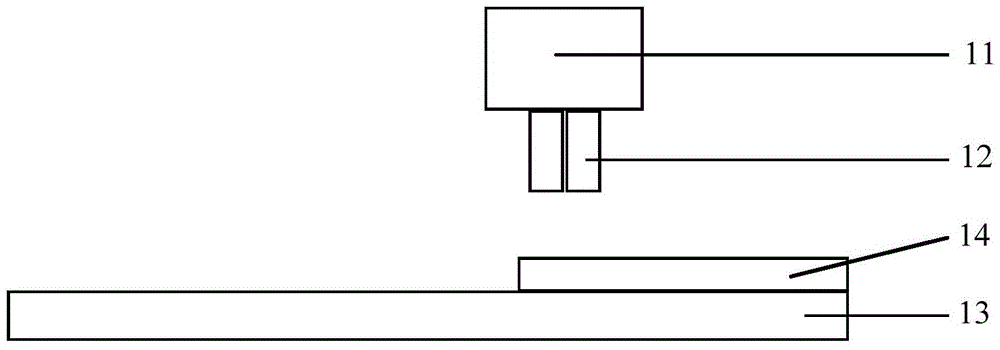

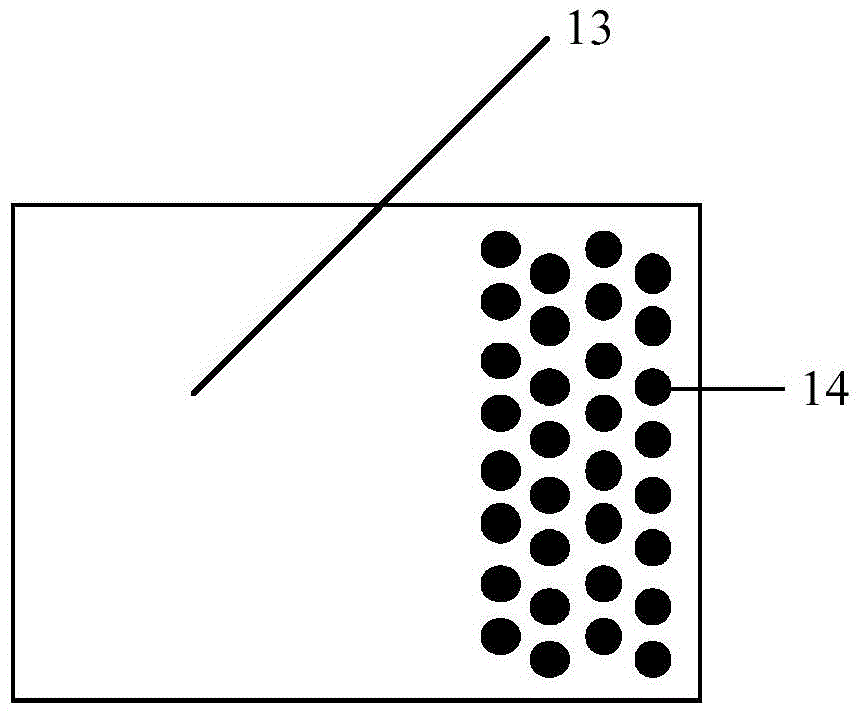

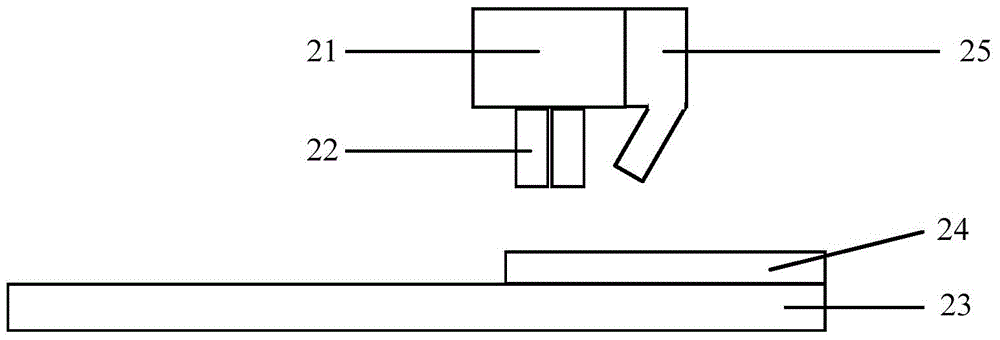

[0022] figure 2 A cross-sectional view of the inkjet printing device according to the embodiment of the present invention in the moving direction of the inkjet head is shown.

[0023] Such as figure 2 As shown, similar to the inkjet printing device in the prior art, the inkjet head 22 on the frame 21 sprays polyimide droplets 24 to the substrate 23 to form an alignment film. Compared with the inkjet printing apparatus in the prior art, the inkjet printing apparatus according to the embodiment of the present invention further includes an air knife (air knife) 25 located behind the inkjet head 22 and fixed on the frame 21 . Herein, "rear" refers to the rear in the moving direction of the inkjet head. Air knife is a drying device, which is widely used in electronics, semiconductor and other industrial fields. It sprays drying gas to components to dry, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com