A kind of processing technology of non-hormonal anti-inflammatory drug intermediate

A quinoline-based, vinyl-based technology, applied in the processing technology of non-hormonal anti-inflammatory drug intermediates, 2--vinyl) phenyl)-propyl) methyl benzoate processing technology field, can solve the problem of increasing The cost of the drug montelukast sodium, low yield, low product quality and other problems, achieve the effect of reducing chemical synthesis steps, reducing costs, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

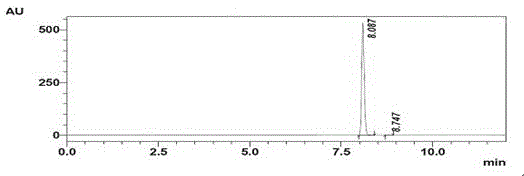

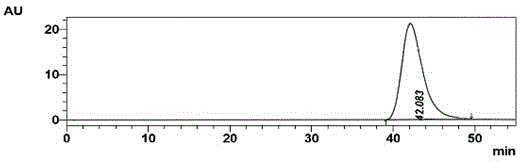

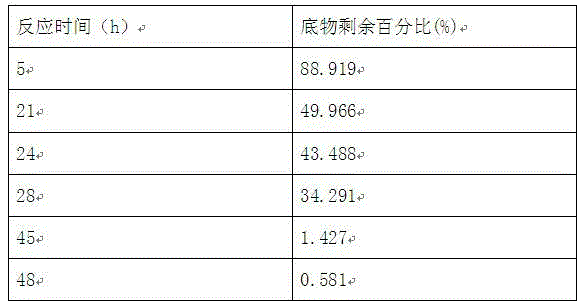

[0022] The measured raw material 2-(3-(3-(2-(7-chloro-2-quinolyl) vinyl) phenyl)-(3-carbonyl) propyl) methyl benzoate 8kg, ketone reduction Put 240g of enzyme, 24L of triethanolamine buffer solution (2MMgSO4), 40L of isopropanol, and 8L of toluene into a clean 250 L stainless steel kettle with magnetic stirring in sequence, and add cofactor aqueous solution: 50 g / L NADP-Na; heat up to 45°C , and reacted under magnetic stirring; 50 g / L NADP-Na was added after 6 hours of reaction, 50 g / L NADP-Na was added after 22 hours of reaction, and 50 g / L NADP-Na was added after 29 hours of reaction. Sampling began after 40 hours of reaction, and the reaction was complete in about 48 hours; after the detection was complete, proceed to the next step. Evaporate the organic solvent from the reaction liquid at low temperature in a vacuum, cool, filter, centrifuge, and dry to obtain the crude product; take the crude product, add 80KG ethanol, heat up to 50°C while stirring, and the solution is c...

Embodiment 2

[0026] The measured raw material 2-(3-(3-(2-(7-chloro-2-quinolyl)vinyl)phenyl)-(3-carbonyl)propyl)methyl benzoate 10kg, ketone reduction Put 400g of enzyme, 25L of triethanolamine buffer solution (2MMgSO4), 30L of isopropanol, and 6L of toluene into a clean 250 L stainless steel kettle with magnetic stirring in sequence, and add cofactor aqueous solution: 50 g / L NADP-Na; heat up to 45°C , and reacted under magnetic stirring; 50 g / L NADP-Na was added after 6 hours of reaction, 50 g / L NADP-Na was added after 22 hours of reaction, and 50 g / L NADP-Na was added after 29 hours of reaction. Sampling began after 40 hours of reaction, and the reaction was complete in about 48 hours; after the detection was complete, proceed to the next step. Evaporate the organic solvent from the reaction liquid at low temperature in a vacuum, cool, filter, centrifuge, and dry to obtain the crude product; take the crude product, add 80KG ethanol, heat up to 50°C while stirring, and the solution is clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com