Doffing parent-subsidiary car device with four-bar lifting mechanism

A lifting mechanism and four-bar linkage technology, applied in textiles and papermaking, etc., can solve the problems of reducing labor intensity, low degree of automation, and inability to adjust the height of the machine, reducing power loss, prolonging service life, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The content of the specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

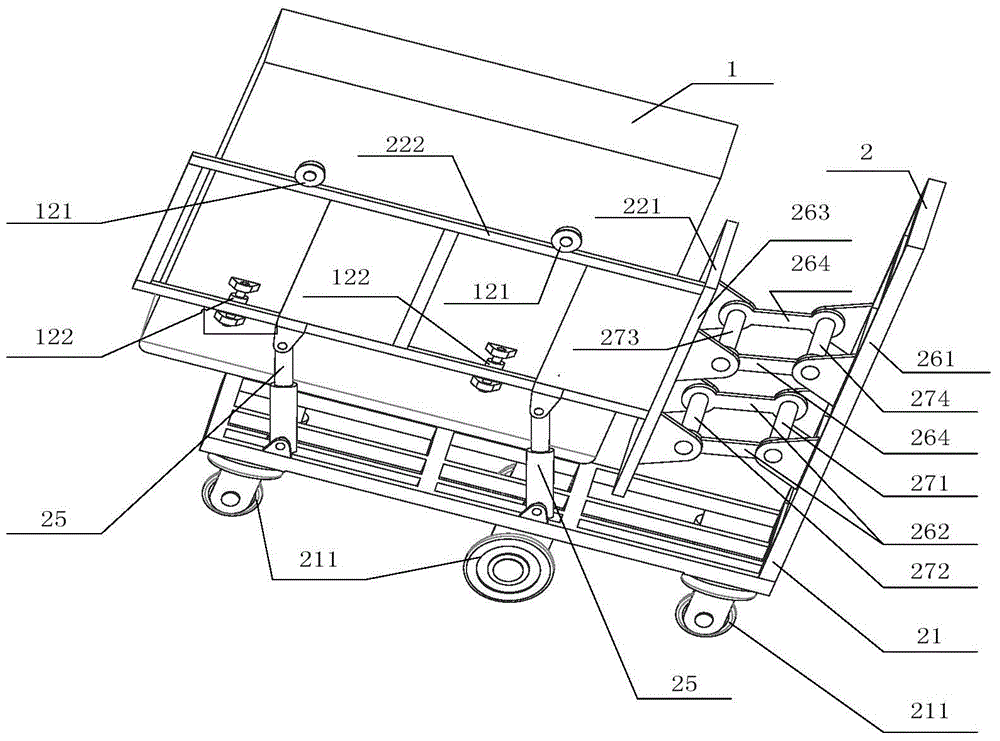

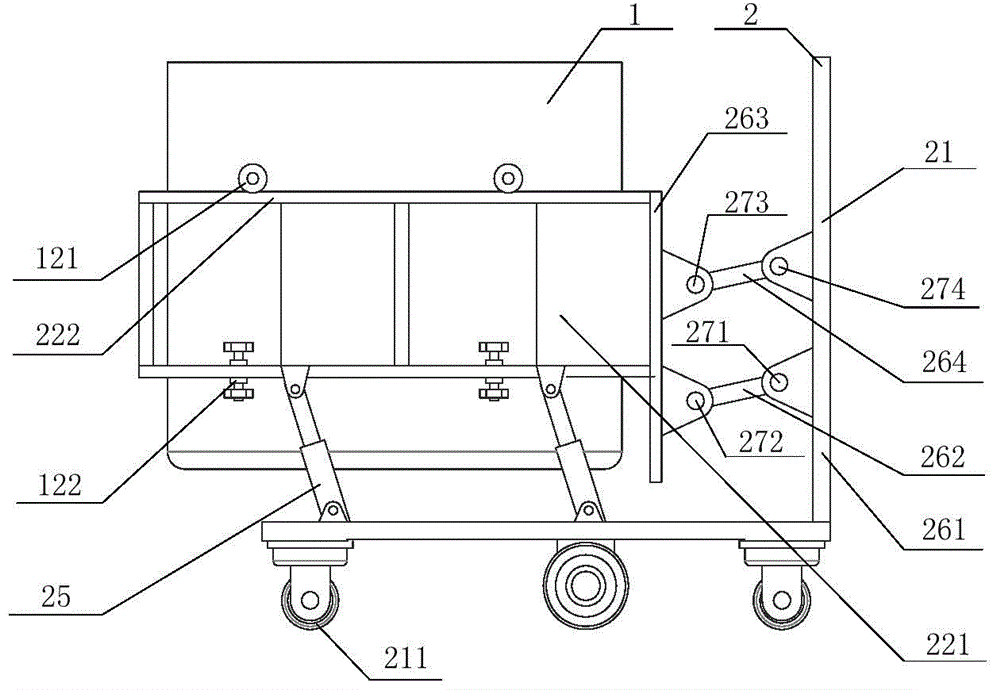

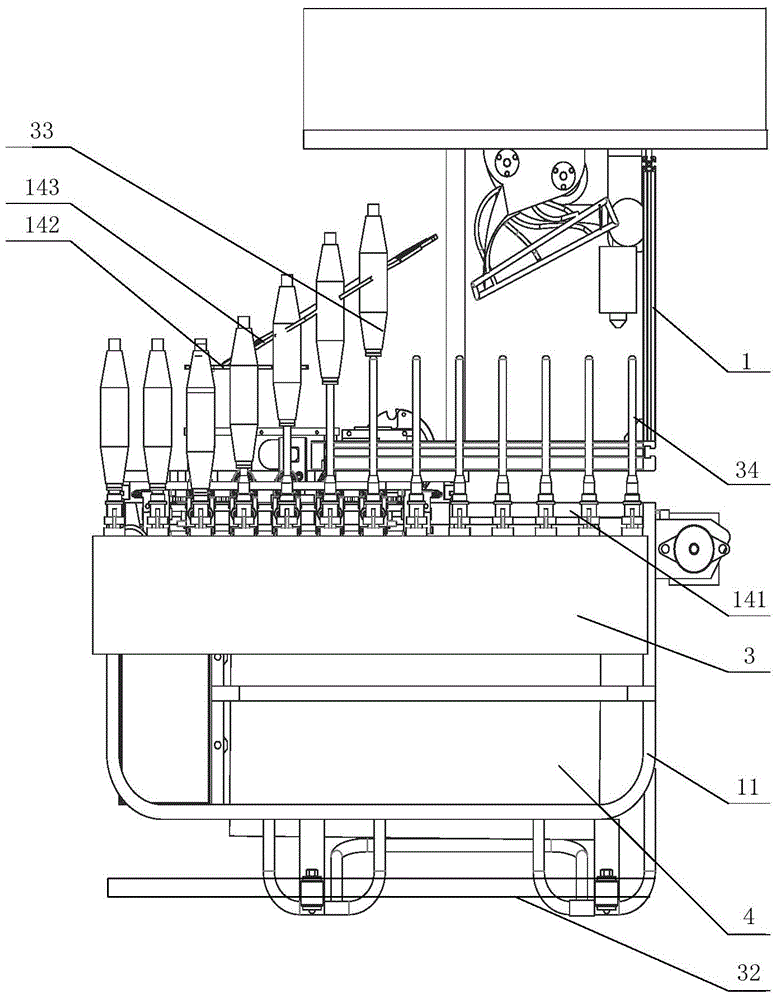

[0037] An embodiment of a doffing master car device with a four-link lifting mechanism designed by the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, a doffing car 1 is included, and the doffing car 1 includes a car body 11, a suspension mechanism and a running mechanism. The suspension mechanism and the running mechanism are respectively installed on the car body 11, and the suspension mechanism includes at least two guides wheel 121 and at least one support wheel 122; all the guide wheels 121 and support wheels 122 are respectively movably socketed on the vehicle body 11; the traveling mechanism includes a first motor 131 and a first transmission mechanism 132; the first A motor 131 is installed on the car body 11; the device also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com