Multiple-sealing full-welding pipeline ball valve

A multi-sealing and all-welding technology, which is applied to the valve details, valve device, valve shell structure, etc., can solve the problems that pipeline ball valves cannot meet, and achieve the effect of meeting the sealing performance and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

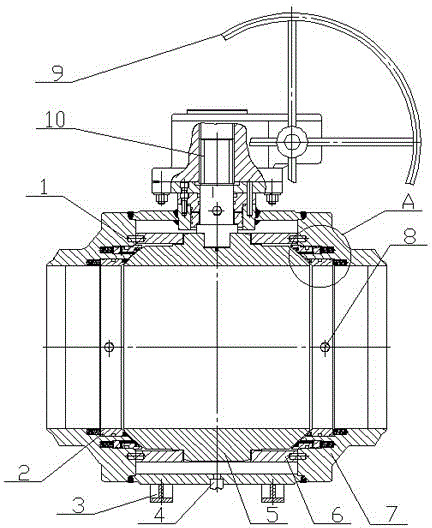

[0007] Such as figure 1 As shown, the present invention is a multi-seal fully welded pipeline ball valve, including a valve ball 5, a valve body 7, and a valve stem 10. The valve body 7 is a spherical structure, formed by hot forging of the left and right valve bodies, and welded by a single weld in the middle; The lower part of the valve body 7 is provided with supporting legs 3;

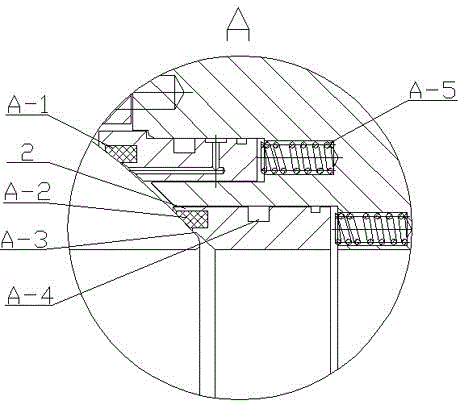

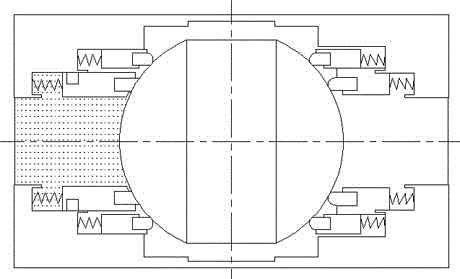

[0008] Such as figure 1 , figure 2 As shown, there are multiple seal structures on the valve seat: the first seal is the soft seal A-2 in front of the valve; the second seal is the soft seal A-1; the preload spring A-4 is preset at the valve seat.

[0009] Such as figure 1 As shown, the support seat 6 and the valve body 7 are connected and fixed by the pin 1 . Such as figure 1 , figure 2 As shown, the contact between the valve seat 2 and the valve body 7 is provided with a graphite sealing ring A-3.

[0010] The working process of the present invention is: when the ball valve is in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com