LED module

A technology of LED modules and cooling blocks, which is applied in the cooling/heating devices of lighting devices, lighting and heating equipment, electrical components, etc., and can solve the problem that the shape and power cannot be adjusted, and the brightness of LED lighting cannot be greatly increased. increase and other issues, to achieve the effect of improving LED constant current driving effect, good protection performance, and reducing power supply requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

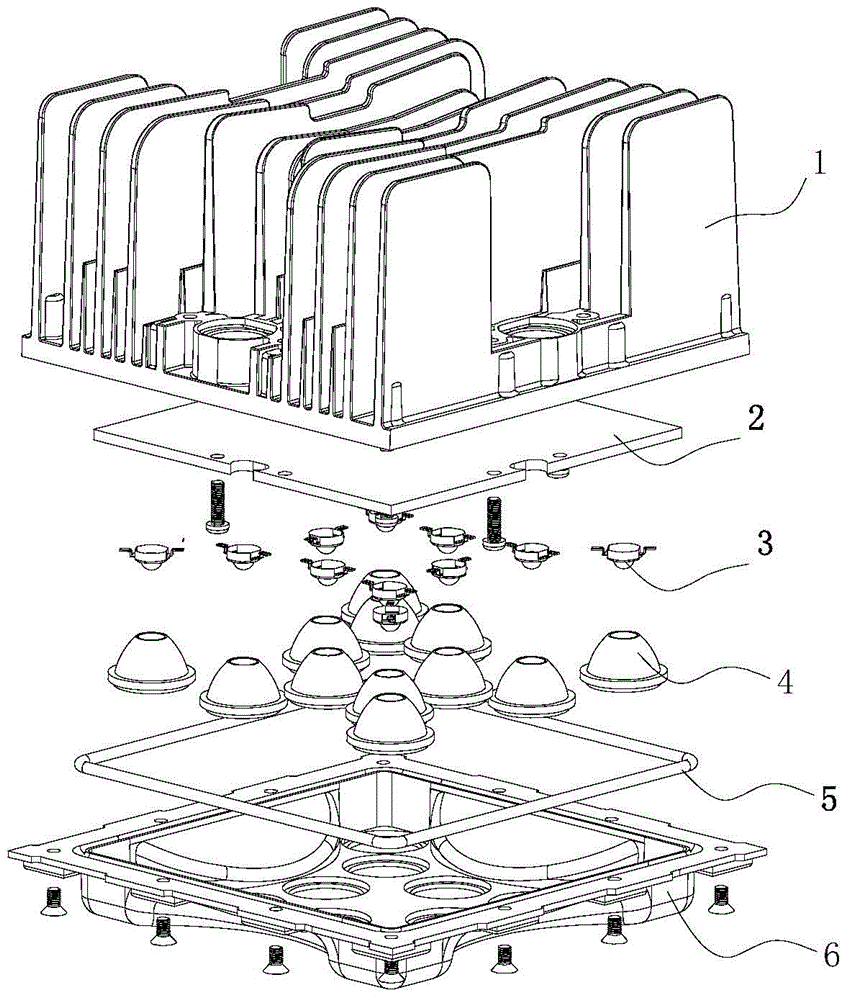

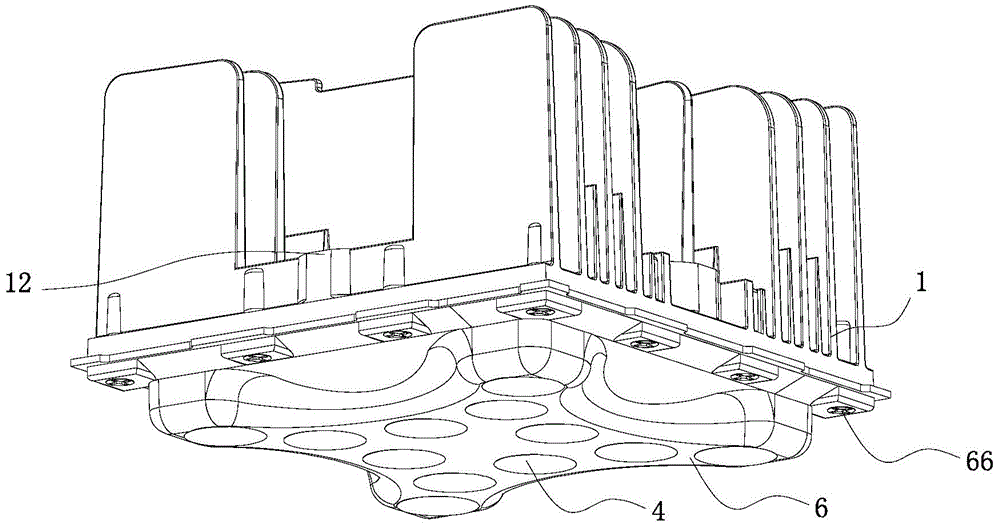

[0027] like Figure 1-7 The LED module shown mainly includes LED 3 , PCB board 2 , lens 4 , lens mask 6 and cooling block 1 .

[0028] LED3 is installed on the PCB board 2, specifically, the bottom of LED3 is integrally connected to the PCB board 2, so as to reduce the power supply requirements and reduce the unit size, which not only effectively reduces the requirements for power supply performance, but also compresses the volume space. The IC chip 22 on the PCB board 2 controls the working current and working heat of the LED through pulse width modulation, and adjusts the voltage regulation and constant current by changing the duty cycle.

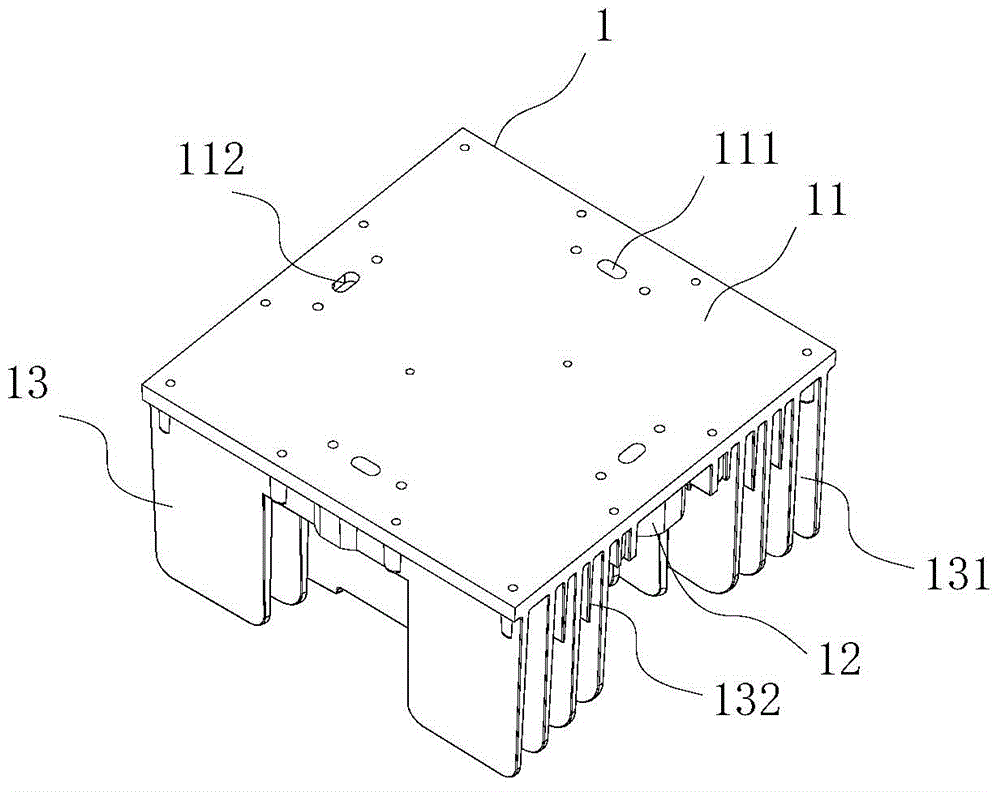

[0029] The heat dissipation block 1 is an integral aluminum heat dissipation block, and the heat dissipation block 1 is composed of a fixed panel 11 and a connection assembly 12 and a heat dissipation plate 13 thereon. The PCB board 2 is fixed on the bottom surface of the fixed panel 11, the bottom of the cooling plate 13 and the connect...

Embodiment 2

[0042] like Figure 8 The other structure of the LED module shown is the same as that of the LED module in Embodiment 1, and some structures and functions are added on the basis of Embodiment 1. Specifically, the heat sink plate 13 in the middle is provided with a screw hole connected with it The mounting column 133 has an opening of the screw hole upwards, and a connecting plate 134 is installed on the mounting column 133. The mounting screws pass through the connecting plate 134 and are fixed on the mounting column 133. The connecting plate 134 can be used for installing and fixing the entire LED module. An electrical connector 124 is provided on the connecting assembly 12 for docking with the LED module, and the electrical connecting head 124 is treated with IP protection, that is, sealing and waterproof gaskets are provided on the upper and lower sides of the electrical connecting head 124, and in addition, on the connecting assembly 12 that is not used for docking , plug ...

Embodiment 3

[0044] like Figure 9 The other structures of the LED module shown are the same as that of the LED module in Embodiment 1, and some structures and functions are added on the basis of Embodiment 1. Specifically, a mounting connection plate 123 is set on the connection assembly 12, and the screws pass through the mounting connection The board 123 is fixed in the connecting hole 125, and the connecting board 123 is installed with a hole. The connection assembly 12 does not have a docking function but an installation function, and can be used for installation and fixing of the entire LED module by installing the connection plate 123 . In addition, the heat sink plate 13 in the middle is provided with a mounting column 133 with a screw hole integrally connected with it, and the opening of the screw hole is upward, and the mounting column 133 can be used for fixing the LED module in other ways. An electrical connector 124 is provided on the connection assembly 12 for docking with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com