Accurate temperature measuring system for high-voltage switch cabinet busbar

A technology for high-voltage switchgear and accurate temperature measurement, which is applied in the field of temperature measurement systems, can solve problems such as the inability to accurately detect the temperature of busbars with protective sleeves, and achieve the effects of easy installation, easy and safe installation, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

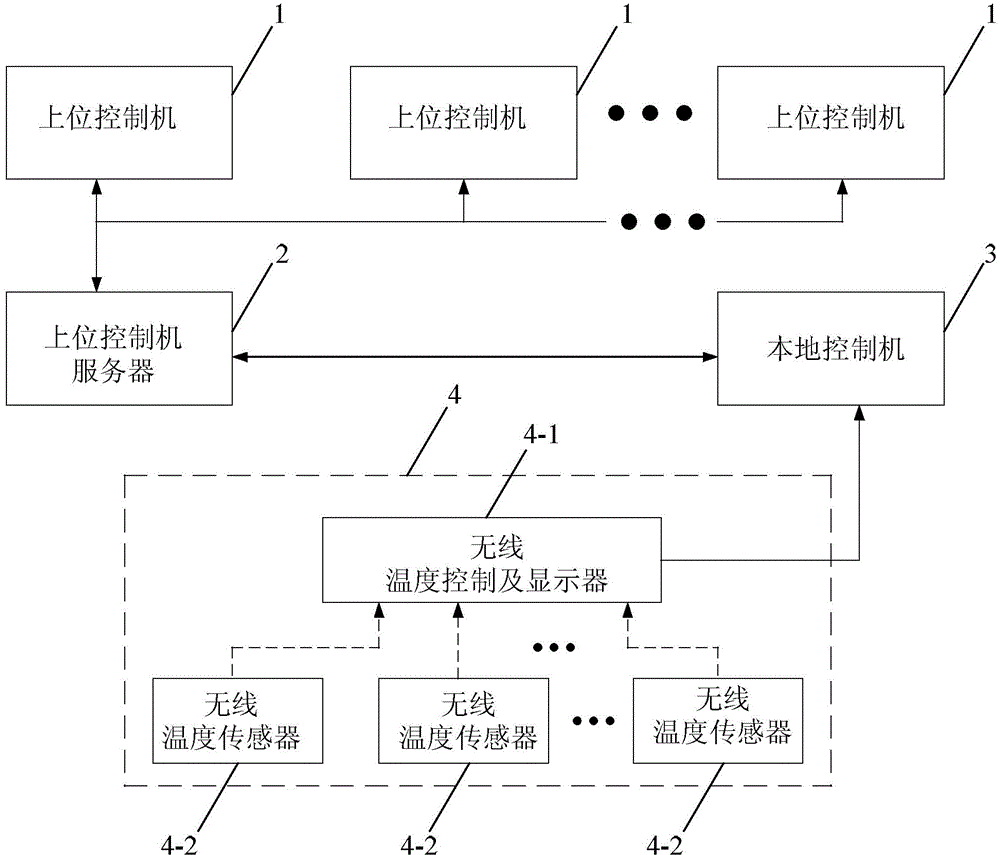

[0013] Specific implementation mode one: combine figure 1 Describe this embodiment, the high-voltage switchgear busbar accurate temperature measurement system described in this embodiment, which includes N upper controllers 1, upper controller servers 2, local controllers 3 and wireless temperature measurement components 4; N is a natural number; The upper control data signal output and input ends of the upper control machine server 2 are connected with the upper control data signal output and input ends of each upper control machine 1 at the same time; the temperature data signal output and input ends of the local control machine 3 are connected with the temperature The data signal output and input terminals are connected; the local temperature data output terminal of the wireless temperature measurement component 4 is connected with the local temperature data input terminal of the local control machine 3, and the temperature collection terminal of the wireless temperature mea...

specific Embodiment approach 2

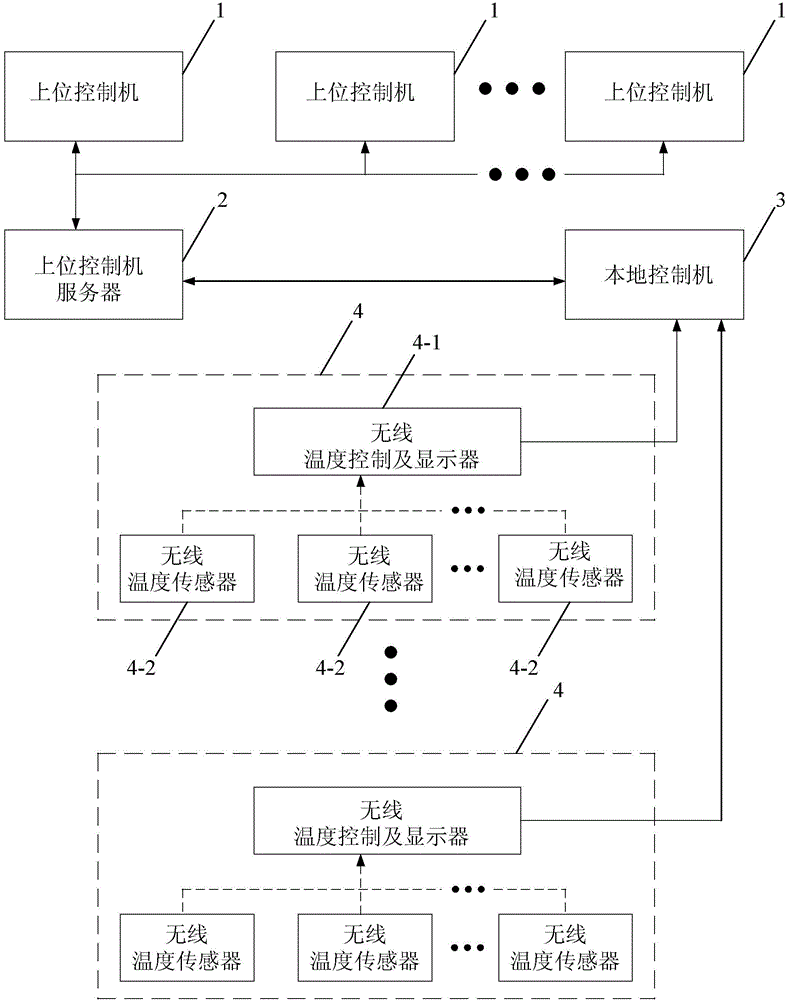

[0014] Specific implementation mode two: combination figure 2 Describe this embodiment, the difference between this embodiment and the specific embodiment is that it also includes M wireless temperature measurement components 4; the structure and composition of the M wireless temperature measurement components 4 are the same; each of the wireless temperature measurement The local end temperature data output end of the component 4 is connected with a local end temperature data input end of the local control machine 3 respectively; The server-side temperature data input port is connected. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 or figure 2 Describe this embodiment, the difference between this embodiment and the second embodiment is that the wireless temperature measurement component 4 includes a wireless temperature control and display 4-1 and L wireless temperature sensors 4-2; the wireless temperature control and display 4-1 The local end temperature data output end of the wireless temperature measurement assembly 4 is the local end temperature data output end of the wireless temperature measurement component 4; the server end temperature data output end of the wireless temperature control and display 4-1 is the server end temperature of the wireless temperature measurement assembly 4 Data output terminals; the L wireless temperature data input terminals of the wireless temperature control and display 4-1 are connected to the wireless temperature data output terminals of a wireless temperature sensor 4-2 correspondingly. Other compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com