Industrial fixed-focus camera parameter calibration device based on square target model

A square target model and parameter calibration technology, applied in image data processing, instruments, calculations, etc., can solve the problems of immature image processing technology, large manual operation errors, cumbersome process, etc., to simplify the camera calibration process and cost, and facilitate Camera parameters, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

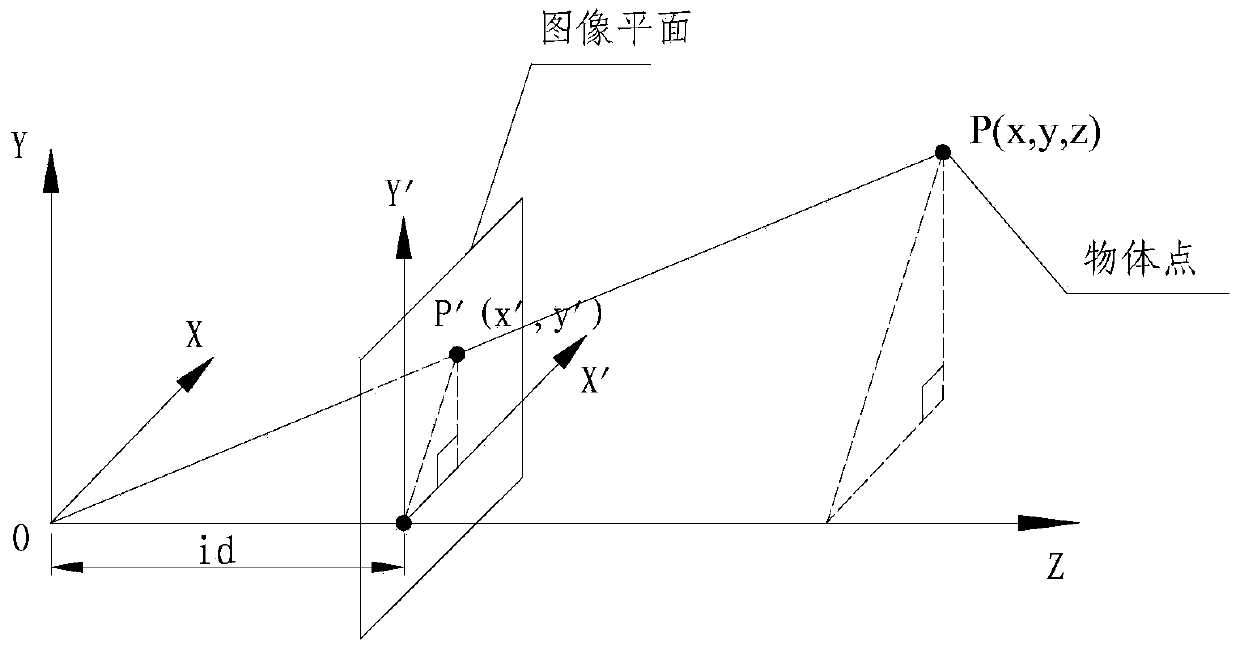

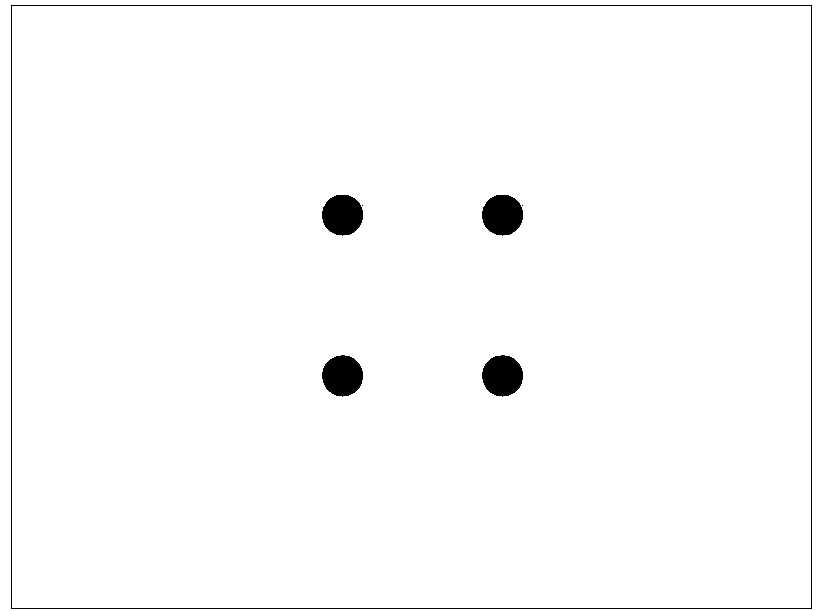

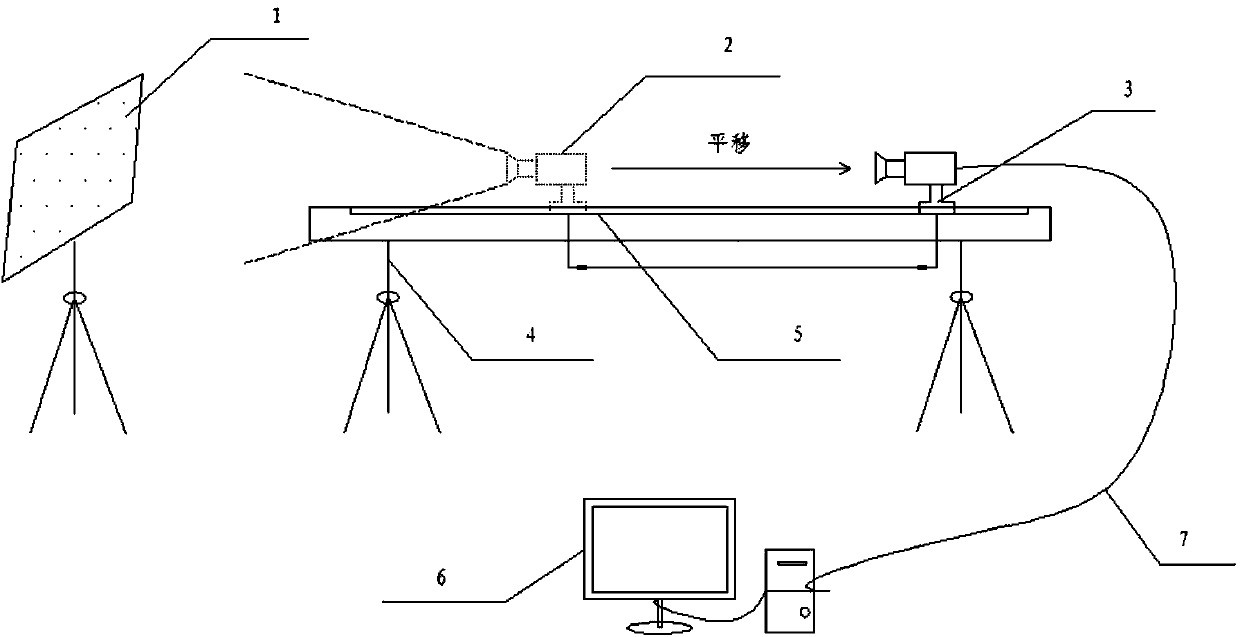

[0023] Such as image 3 As shown, an industrial fixed-focus camera parameter calibration device based on a square target model includes a target 1, a camera translational movement assembly and a PC 6, and the target 1 and the camera translational movement assembly are arranged on the ground at a certain distance. The camera 2 to be calibrated is set on the camera translation movement assembly, and is connected with the PC 6 through the data line 7, as figure 2 As shown, the target 1 is provided with four dots, and the geometric centers of the four dots form a square. A square object will become an arbitrary quadrilateral after projection on the imaging surface of the camera. Through projection transformation adjustment, a square similar to the original object can be easily obtained again, and the position of the square at this time is paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com