Method for recycling residual paste from lead-acid storage battery smear through water rolling and acid rolling

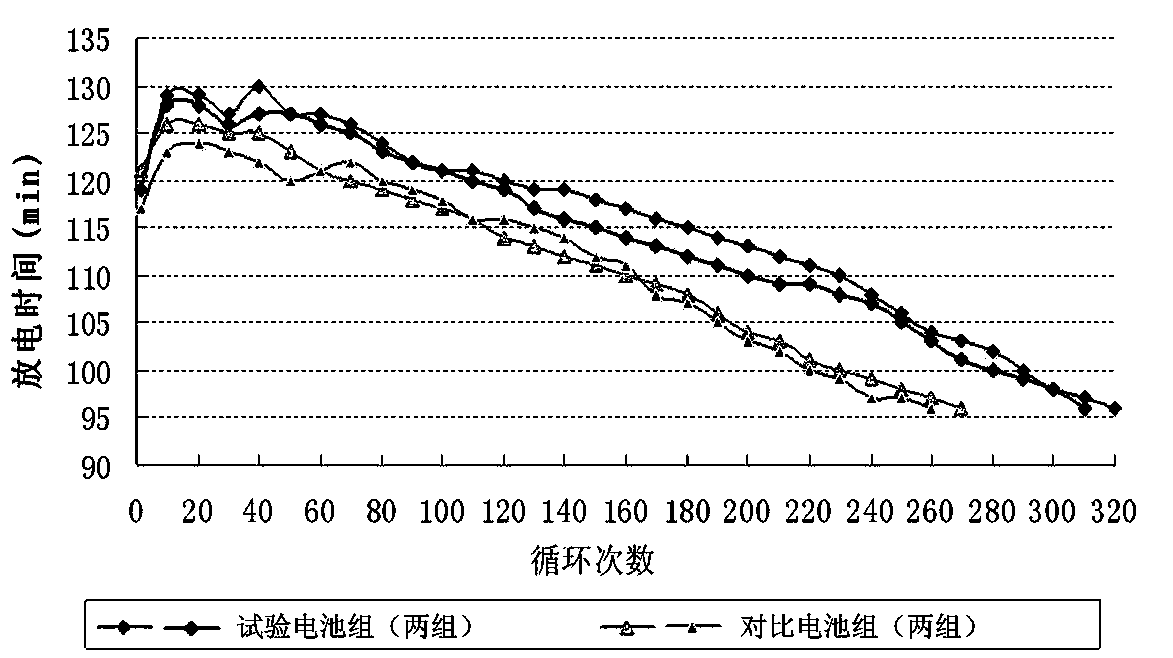

A lead-acid battery and lead paste technology, applied in the direction of lead-acid battery electrodes, battery recycling, recycling technology, etc., can solve the problems of increased battery cost, unstable content, and aggravated pollution discharge pressure of enterprises, so as to ensure performance consistency, The effect of prolonging the cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A method for recovering residual paste by boiling water and boiling acid on a lead-acid battery smear, specifically, it can be realized through the following steps:

[0020] (1) Put the lead paste into the smearing equipment through the lead bucket, use the smearing equipment to apply the lead paste evenly on the lead grid according to a certain weight, and pass the coated lead grid through the first pressing roller, The fluffy lead paste on the surface of the lead grid is compressed evenly and evenly, and the excess lead paste is squeezed out of the lead grid (such as being squeezed to both sides of the lead grid);

[0021] (2) Perform boiling water operation on the lead grid, that is, roll the water evenly on the surface of the lead grid, and under the action of the water flow, wash the extruded lead paste and the loose lead paste on the surface of the lead grid, The lead paste washed out by the above-mentioned boiling water is collected together with the water flow; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com