Heat dissipation structure and electronic device

A technology of heat dissipation structure and sub-air duct, applied in the direction of cooling/ventilation/heating transformation, can solve the problem of uneven current flow between two power units, affecting the performance of photovoltaic inverters, etc., to eliminate the phenomenon of thermal cascade, current The effect of equalizing flow and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0034] The electronic device provided by the embodiment of the present invention includes a casing (not shown) and a heat dissipation structure 100 installed in the casing.

[0035] In this embodiment, the electronic device is a photovoltaic inverter.

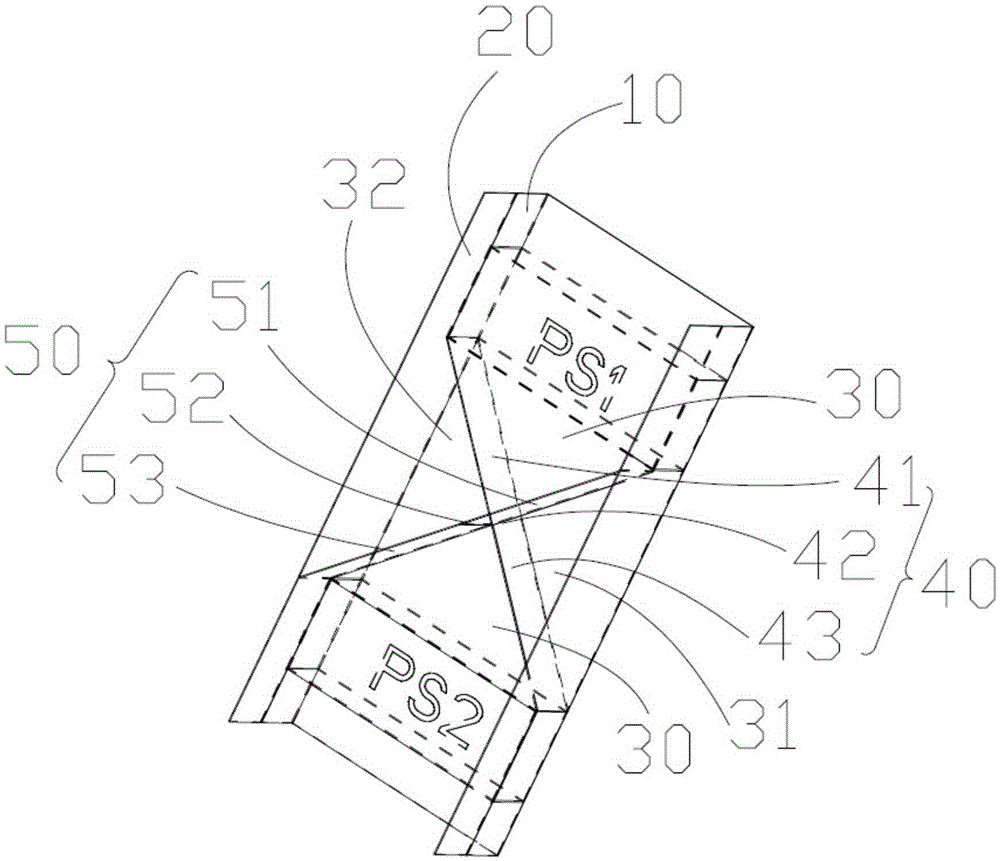

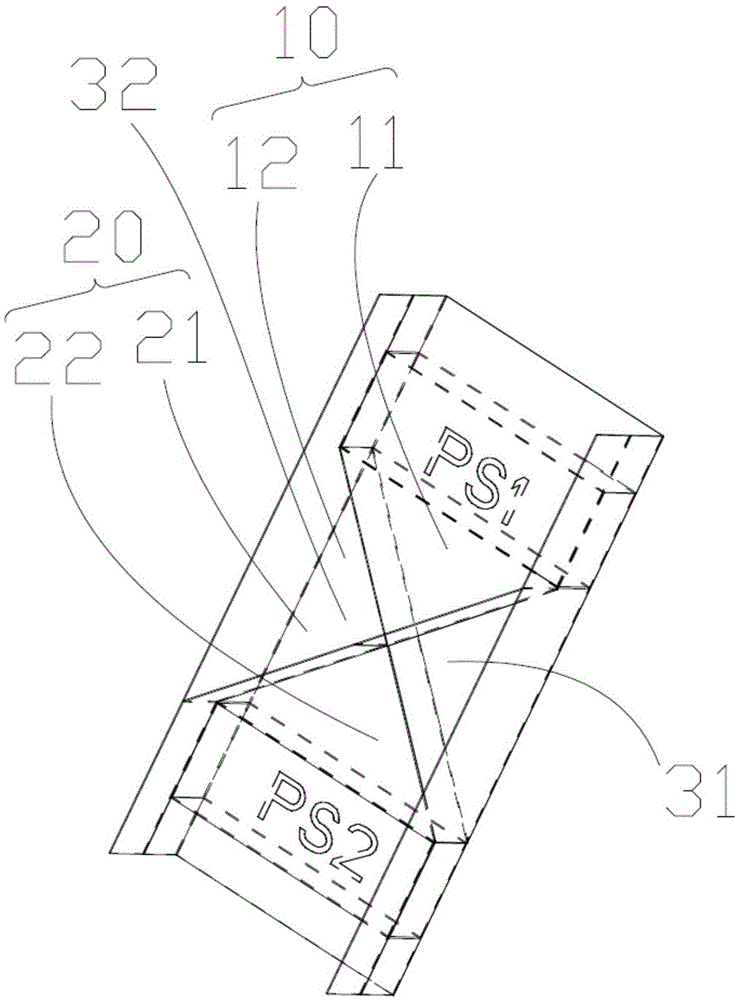

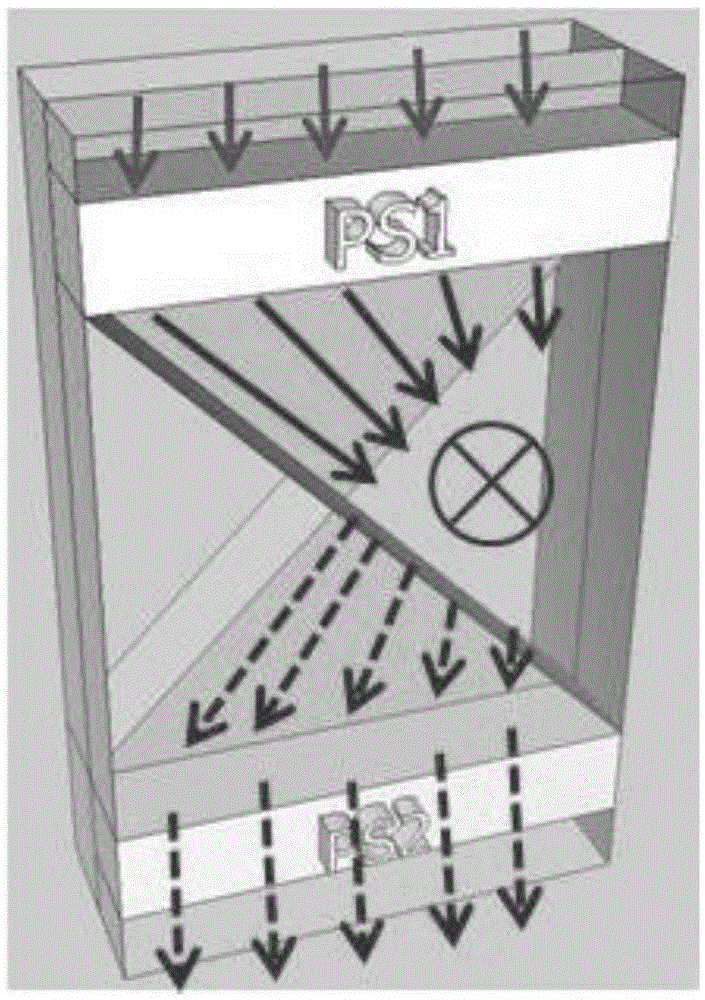

[0036] Please also refer to figure 1 and figure 2 , which is a perspective view of the heat dissipation structure 100 in the first embodiment provided by the present invention. In this embodiment, the heat dissipation structure 100 includes a first air duct 10, a second air duct 20, a partition plate 30, a first partition 40, a second partition 50, a first power unit PS1 and a second power unit PS2.

[0037] The partition plate 30 is disposed between the first air passage 10 and the second air passage 20 . The first parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com