Socks and preparing method thereof

A technology for socks and socks bottoms, applied in socks, pantyhose, underwear, etc., can solve the problem of not considering the thermal and wet comfort of the product, achieve superior moisture permeability, improve wicking height and transfer speed, and improve mechanical properties. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

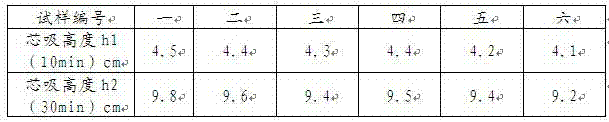

Embodiment 1

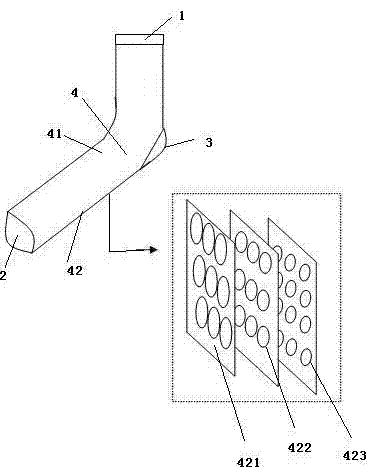

[0053] Such as figure 1 As shown, the socks include a sock opening 1, a sock toe 2, a sock heel 3 and a sock body 4 located in the middle section. The material used for the sock opening 1 is bamboo fiber, feather-free combed cotton and polyester fiber with special-shaped cross-sections. The sock toe 2 and The material used for the sock heel 3 is bamboo fiber, feather-free combed cotton, polyester fiber with special-shaped cross-section, nylon and spandex, and the material used for the sock body 4 is bamboo fiber, feather-free combed cotton, polyester fiber with special-shaped cross-section and spandex;

[0054] Among them, the materials are by quality: triangular section polyester fiber 35%, featherless combed cotton 30%, bamboo fiber 32%, spandex 2%, nylon 1%.

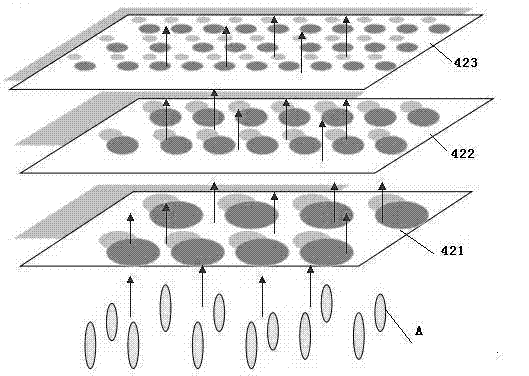

[0055] The sock body 4 includes a sock face 41 and a sock bottom 42 located below the sock face 41, and the capillary diameter of the material gradually becomes thinner from the sock bottom 42 to the sock face 41;

...

Embodiment 2

[0077] Same as Example 1, the difference is 50% polyester fiber with special-shaped cross-section, and its cross-section is cross-shaped; 18% featherless combed cotton, 30% bamboo fiber, 1% spandex; the mass content of nylon is 1%.

Embodiment 3

[0079] Same as Example 2, the difference is 10% polyester fiber with special-shaped cross-section, the cross-section is hollow type; 32% featherless combed cotton, 50% bamboo fiber, 5% spandex; the mass content of nylon is 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com