Preparation of ibuprofen orally-disintegrating pellet coated by compound essence powder and capable of hierarchically releasing drug

A technology of powder coating and orally disintegrating pellets, applied in the field of pharmaceutical preparations, can solve the problems of difficulty in achieving gastric targeting effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

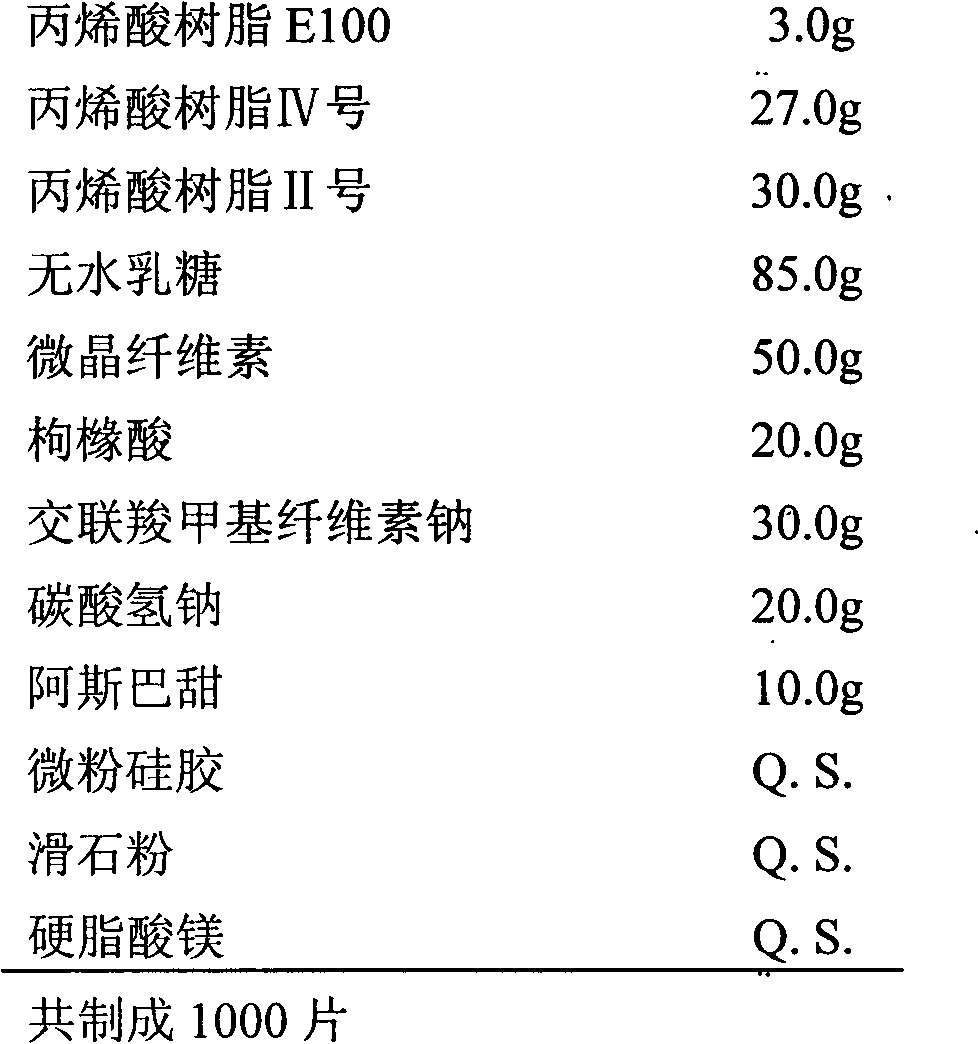

Embodiment 1

[0029]

[0030]

[0031] The preparation method: the ibuprofen is subjected to jet milling and micronization, and the particle size is controlled to be less than 200 μm. Divide the micronized ibuprofen into three parts and carry out powder coating respectively, the steps are as follows:

[0032] (1) Composite essence powder coating, 20g micronized ibuprofen is placed in fluidized bed, sweet orange essence and lemon essence are dispersed in acrylic resin E100 coating material (the ratio of composite essence and coating material is 1: 3) In the process, increase the main ingredient by 10% to obtain 35-50 mesh orally disintegrating pellets (I);

[0033] (2) gastric soluble coating material powder coating, 15g micronized ibuprofen is placed in the fluidized bed, with acrylic resin No. IV as the coating material, the main ingredient is increased by 90%, and the oral cavity of 30~45 objects is obtained Disintegrating pellets (II);

[0034] (3) enteric coating material powder c...

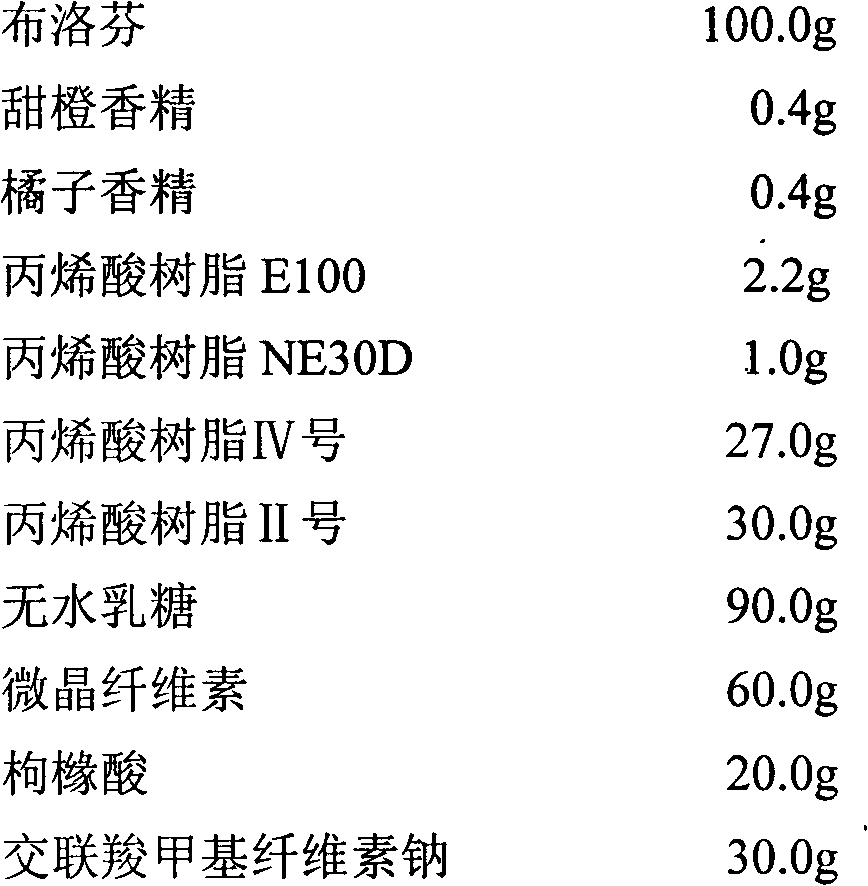

Embodiment 2

[0037]

[0038]

[0039] Preparation method: The ibuprofen is pulverized by ball milling to control its particle size to be less than 200 μm. Divide the micronized ibuprofen into three parts and carry out powder coating respectively, the steps are as follows:

[0040] (1) Composite essence powder coating, 20g micronized ibuprofen is placed in fluidized bed, sweet orange essence and mandarin orange essence are dispersed in acrylic resin E100 and acrylic resin NE30D mixed coating material (composite essence and coating material In the ratio of 1:4), the main ingredient is increased by 10% to obtain 35 to 50 mesh orally disintegrating pellets (I);

[0041] (2) gastric soluble coating material powder coating, 15g micronized ibuprofen is placed in the fluidized bed, with acrylic resin No. IV as the coating material, the main ingredient is increased by 90%, and the oral cavity of 30~45 objects is obtained Disintegrating pellets (II);

[0042] (3) enteric coating material pow...

Embodiment 3

[0045]

[0046] Preparation method: The ibuprofen is pulverized by ball milling to control its particle size to be less than 200 μm. Divide the micronized ibuprofen into three parts and carry out powder coating respectively, the steps are as follows:

[0047] (1) Composite essence powder coating, 20g micronized ibuprofen is placed in fluidized bed, sweet orange essence and mandarin orange essence are dispersed in acrylic resin E100 coating material (the ratio of composite essence and coating material is 1: 7) In the process, increase the main ingredient by 8% to obtain 35-50 mesh orally disintegrating pellets (I);

[0048] (2) gastric soluble coating material powder coating, 15g micronized ibuprofen is placed in the fluidized bed, with acrylic resin No. IV as the coating material, the main ingredient is increased by 100%, and the oral cavity of 30~45 orders is obtained Disintegrating pellets (II);

[0049] (3) enteric coating material powder coating, 15g micronized ibupro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com