Rectifying column for discoloring solvent oil

A rectification tower and solvent oil technology, applied in the field of rectification towers, can solve the problems of high cost of adsorbent and recovery cost, large loss of solvent oil, etc., and achieve the effects of saving adsorbent, improving efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

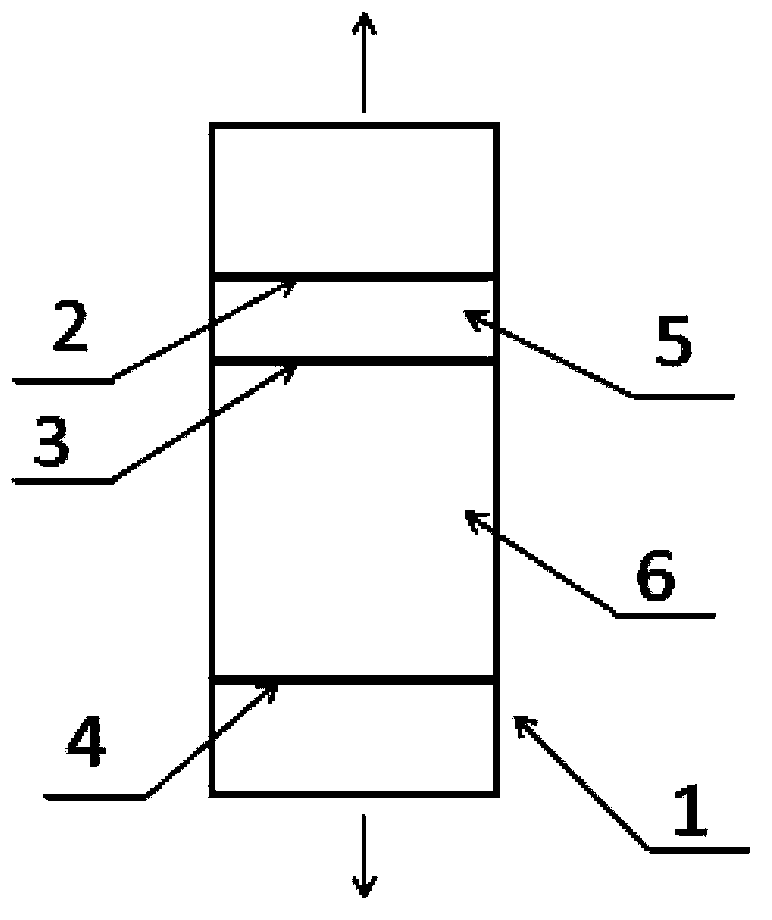

[0014] Such as figure 1 Shown, a kind of rectification tower that is used for solvent oil decolorization, comprises rectification tower body 1, is provided with the first perforated plate 2, the second perforated plate 3, the first perforated plate 2 from top to bottom in the rectification tower body 1. Three porous plates 4, solid adsorbent is filled between the first porous plate 2 and the second porous plate 3, forming an adsorption section 5, between the second porous plate 3 and the third porous plate 4 Fill packing to form rectification section 6. The first perforated plate 2, the second perforated plate 3, and the third perforated plate 4 are all circular plates with through holes on the top, and the aperture of the through holes is smaller than the diameter of the solid filler and also smaller than the diameter of the solid adsorbent. diameter of. The solid adsorbent is activated carbon particle adsorbent. The solid packing is structured packing.

[0015] No. 11 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com