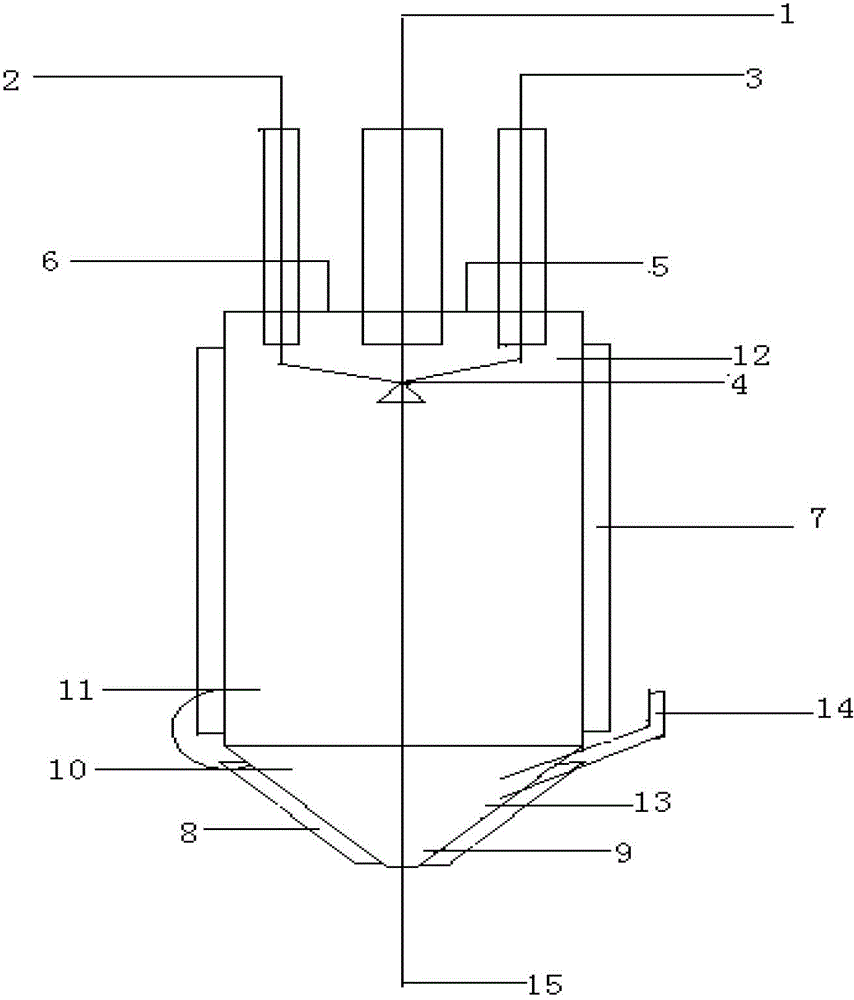

Adjustable Lower Spray Membrane Sulfonation Reactor and Its Application

A technology of sulfonation reactor and spray membrane, which is applied in thin-film liquid-gas reaction, sulfonic acid preparation, organic chemistry, etc. It can solve the problem of sulfonation that affects the quality of the reaction, is easy to block the airway, and cannot adapt to different properties. Raw materials and other issues to achieve the effect of improving reaction efficiency and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Naphthenic distillate 1: distillation range 300-450°C, gum + asphaltenes 7.24%, aromatics content C A 19.31%, 40°C viscosity 65.7mm 2 / s.

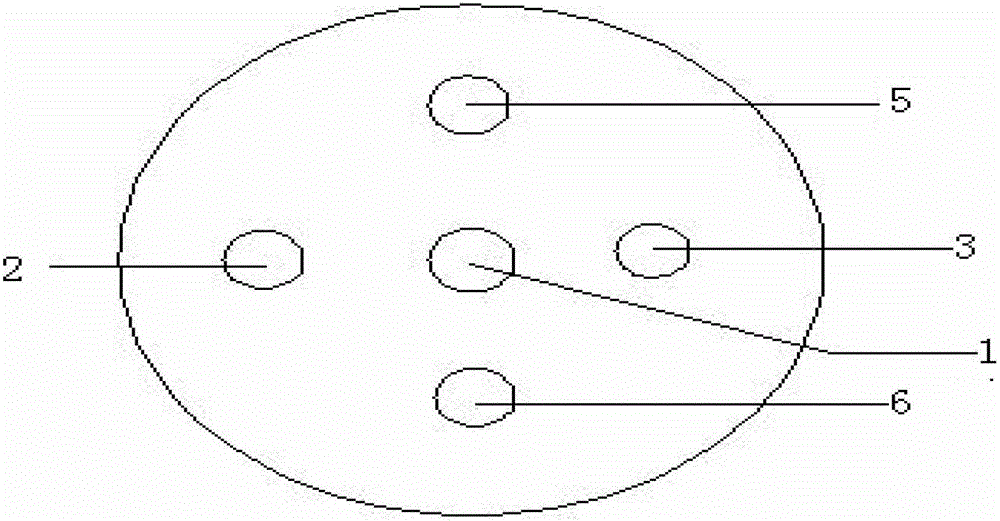

[0035] The volume concentration is 1%, and the sulfur trioxide gas with a mass flow ratio of 0.1:1 to the aromatics in the sulfonation raw material enters the reaction tank through the sulfur trioxide gas inlet 1, and the sulfonation raw material is metered by the raw material pump from the sulfonated raw material inlet. 3 enter, the volume ratio of the liquid intake per hour to the reaction tank is 0.005:1, the compressed air enters from the compressed air inlet 2, and the volume ratio of the intake volume per hour to the liquid intake per hour of the sulfonated raw material is 20: 1. The two are atomized into oil vapor through the stainless steel corner adjustable solid cone nozzle and react with sulfur trioxide gas instantaneously. The tip angle of the cone-shaped spray sprayed by the nozzle is 30°C. The reaction temperature w...

Embodiment 2

[0037] Naphthenic distillate 2: distillation range 350-500°C, gum + asphaltenes 8.1%, aromatics 21.86%, viscosity 287.1mm at 40°C 2 / s, flash point 210°C.

[0038] The volume concentration is 4%, and the sulfur trioxide gas with a mass flow ratio of 1:1 to the aromatics in the sulfonation raw material enters the reaction tank through the sulfur trioxide gas inlet 1, and the sulfonation raw material is metered by the raw material pump from the sulfonated raw material inlet. 3 enter, the volume ratio of the liquid intake per hour to the reaction tank is 0.1:1, the compressed air enters from the compressed air inlet 2, and the volume ratio of the intake volume per hour to the liquid intake per hour of the sulfonated raw material is 1000: 1. The two are atomized into oil vapor through the stainless steel corner adjustable solid cone nozzle and react with sulfur trioxide gas instantaneously. The tip angle of the cone-shaped spray sprayed by the nozzle is 50°C. The reaction temper...

Embodiment 3

[0040] Paraffin-based distillate 3: distillation range 300-450°C, gum + asphaltenes 4.23%, aromatics 9.96%, viscosity 64.7mm at 40°C 2 / s, flash point 183°C.

[0041] The volume concentration is 7%, and the sulfur trioxide gas with a mass flow ratio of 2:1 to the aromatic hydrocarbons in the sulfonation raw material enters the reaction tank through the sulfur trioxide gas inlet 1, and the sulfonation raw material is metered by the raw material pump from the sulfonated raw material inlet. 3 enter, the volume ratio of the liquid intake per hour to the reaction tank is 0.25:1, the compressed air enters from the compressed air inlet 2, and the volume ratio of the intake per hour to the liquid intake per hour of the sulfonated raw material is 3000: 1. The two are atomized into oil vapor through the stainless steel corner adjustable solid cone nozzle and react with sulfur trioxide gas instantaneously. The tip angle of the cone-shaped spray sprayed by the nozzle is 70°C. The reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com