Forced-dispersed quantitative aerosol release device and use method thereof

A technology of forced dispersion and release device, which is applied in the field of poisoning experiments, can solve the problems of poor poisoning effect, general atomization effect, and easy hanging of liquid medicine on the wall, etc. The effect of poison testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

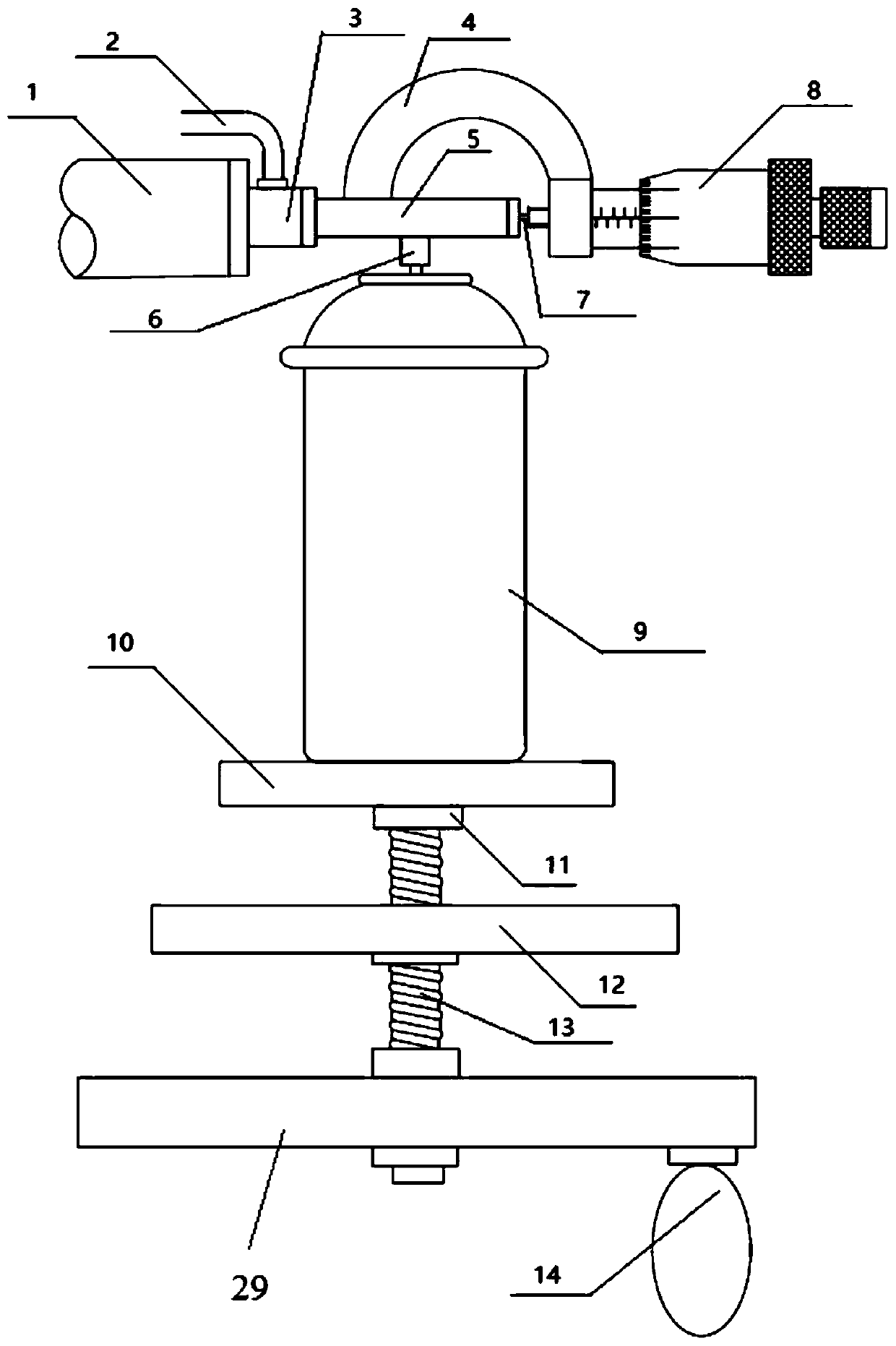

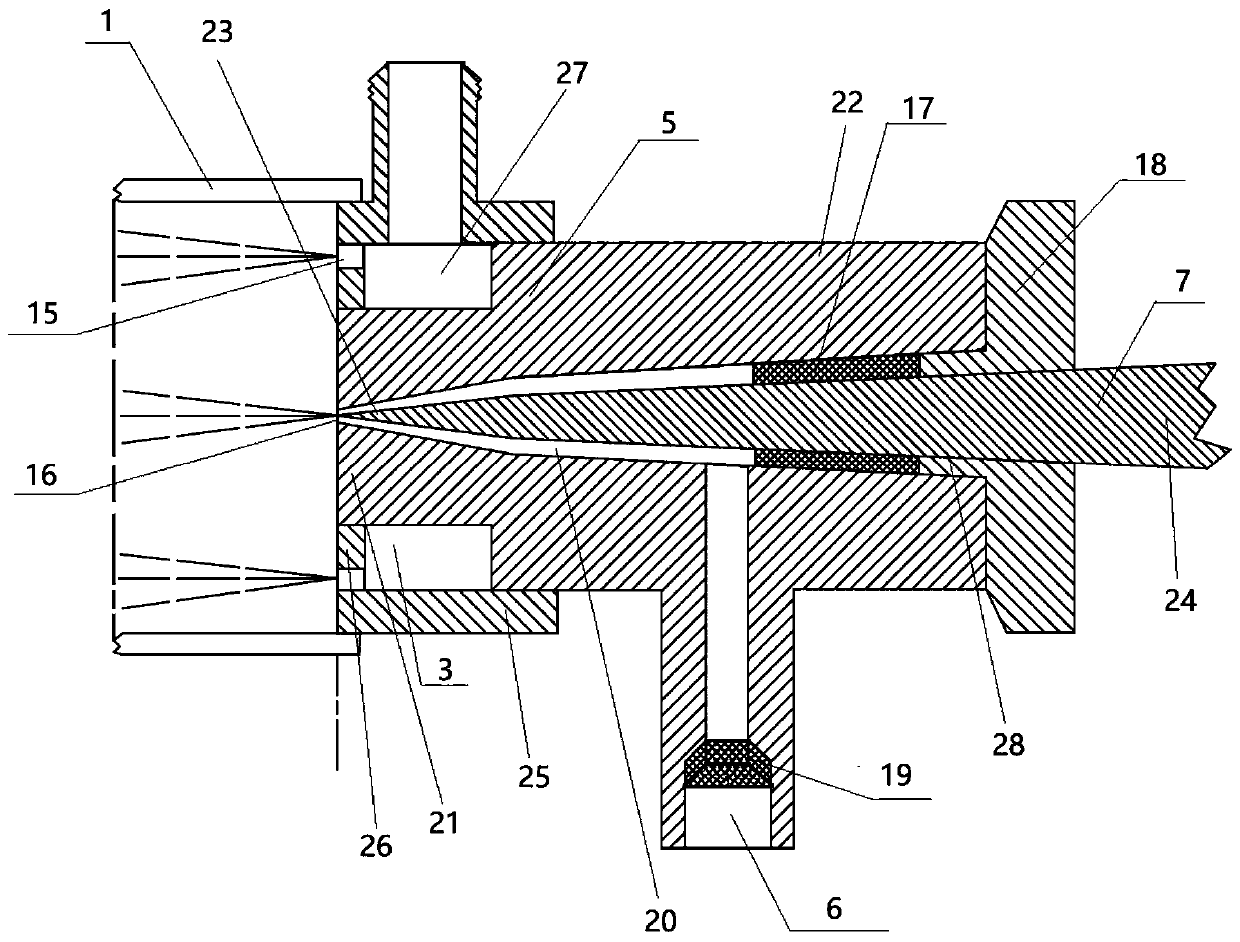

[0031] Such as figure 1 As shown, a forced dispersed aerosol quantitative release device includes an aerosol can 9, the lower part of the aerosol can 9 is provided with a support unit, and the top of the aerosol can 9 is provided with a regulating valve unit for controlling the output of the aerosol can 9 , the regulating valve unit includes a valve body 5, a vaporization chamber 20 is arranged in the valve body 5, and an adjustable valve needle 7 is arranged in the vaporization chamber 20 for controlling the displacement of the aerosol, at the outlet of the valve body 5 An air distribution ring 3 is set, the valve body 5 is connected to the mixing exhaust pipe 1 through the air distribution ring 3, the air distribution ring 3 passes through the gas inlet pipe 2 into compressed gas, and the compressed gas and the vaporization chamber 20 of the valve body 5 come out After the aerosol is mixed, it is discharged from the mixing exhaust pipe 1 together, wherein the valve needle 7 ...

Embodiment 2

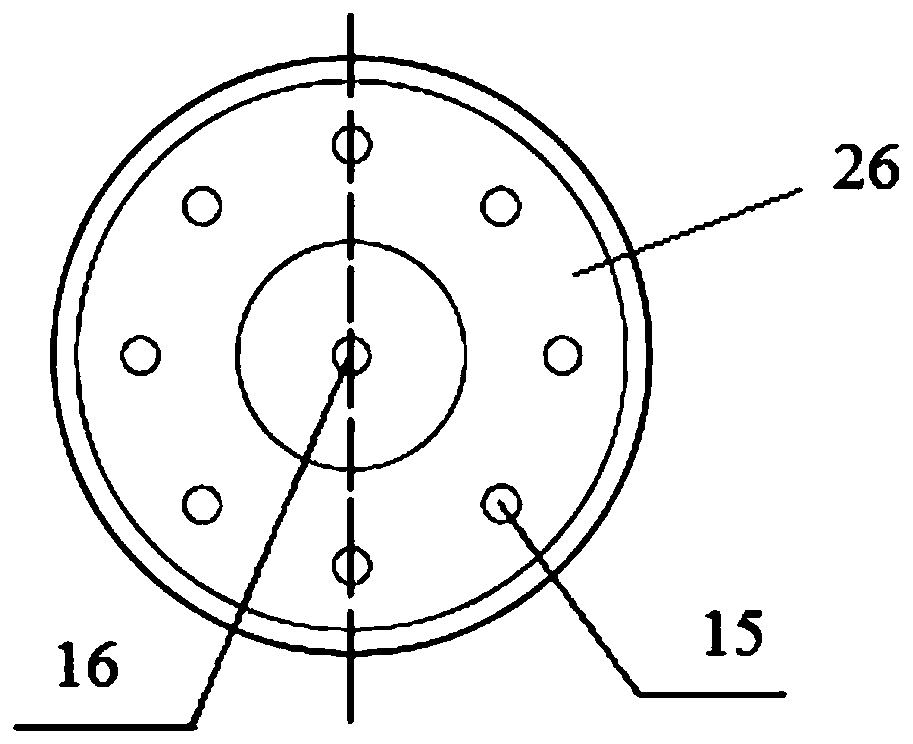

[0040] A forced dispersion type aerosol quantitative release device, which is basically the same as that of Embodiment 1, wherein the gas nozzles 15 are evenly and symmetrically arranged with the aerosol nozzle 16 as the center of the circle, and there are 6 gas nozzles in total.

Embodiment 3

[0042] A forced dispersion type aerosol quantitative release device is basically the same as that of Embodiment 1, wherein the gas nozzles 15 are uniformly and symmetrically arranged with the aerosol nozzle 16 as the center of the circle, and there are 10 gas nozzles in total.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com