Automatic cleaning method of household food processor

A food processing machine and automatic cleaning technology, which is applied to cleaning methods using liquids, cleaning methods and utensils, household utensils, etc., can solve customers' problems such as difficult cleaning, sticking, and increased difficulty of food processing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

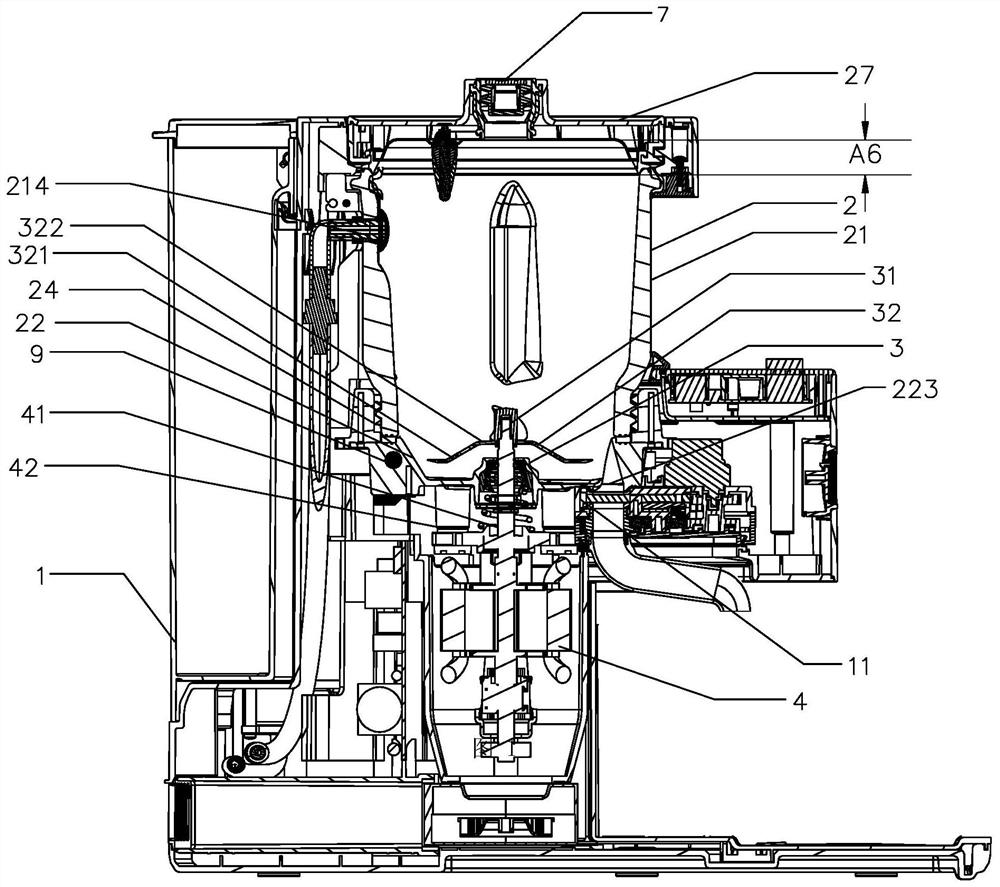

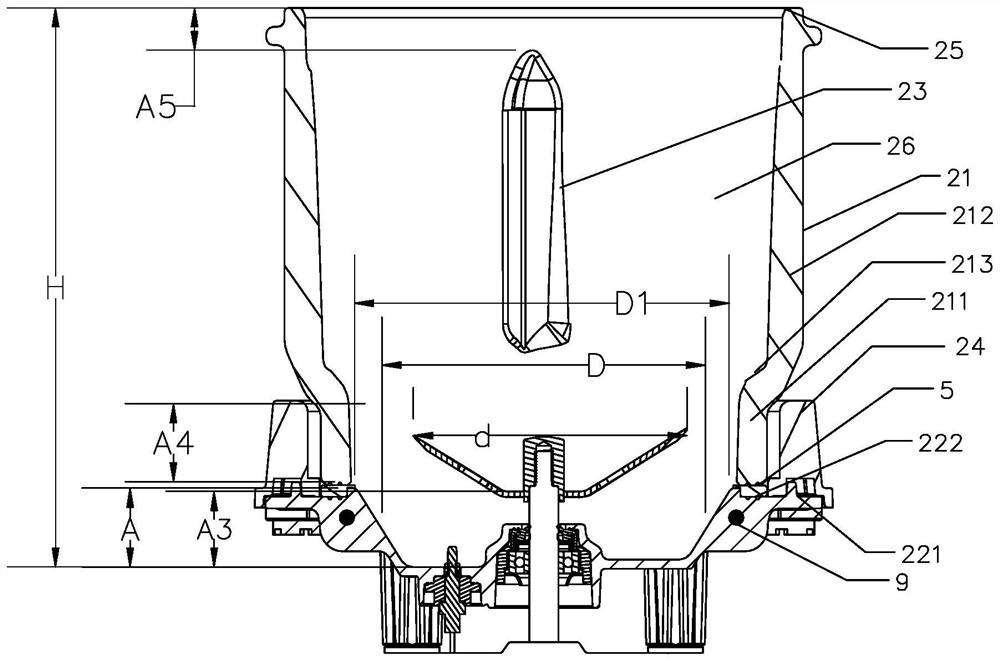

[0046] Such as Figure 1 to Figure 2 As shown, the present invention provides an automatic cleaning method for a household food processor. The food processor includes a body 1, a motor 4, a cutter assembly 3, a stirring cup 2 and a cup that is closed on the opening 25 of the stirring cup 2. Cover 27, the stirring cup 2 includes a glass body 21 with openings both up and down, and a metal plate 22, the glass body 21 and the metal plate 22 are sealed and connected as one, and the cutter assembly 3 includes a cutter shaft 31 and a blade set on the cutter shaft 31 The smashing knife 32 at the top, the knife shaft 31 extends upwards into the stirring cup 2 through the opening in the center of the metal plate 22, the motor 4 drives the smashing knife 32 to rotate, and the cup cover 27, the glass body 21 and the metal plate 22 are enclosed to form a stirring Cup cavity 26, the capacity of the stirring cup cavity 26 is V, the cavity height of the stirring cup is H, the average depth of...

Embodiment 2

[0098] The difference between this embodiment and the first embodiment lies in that the connection structure between the stirring cup of the food processor and the machine body and the dimension parameters of the cup body are different, so the cleaning method of the food processor is also slightly different.

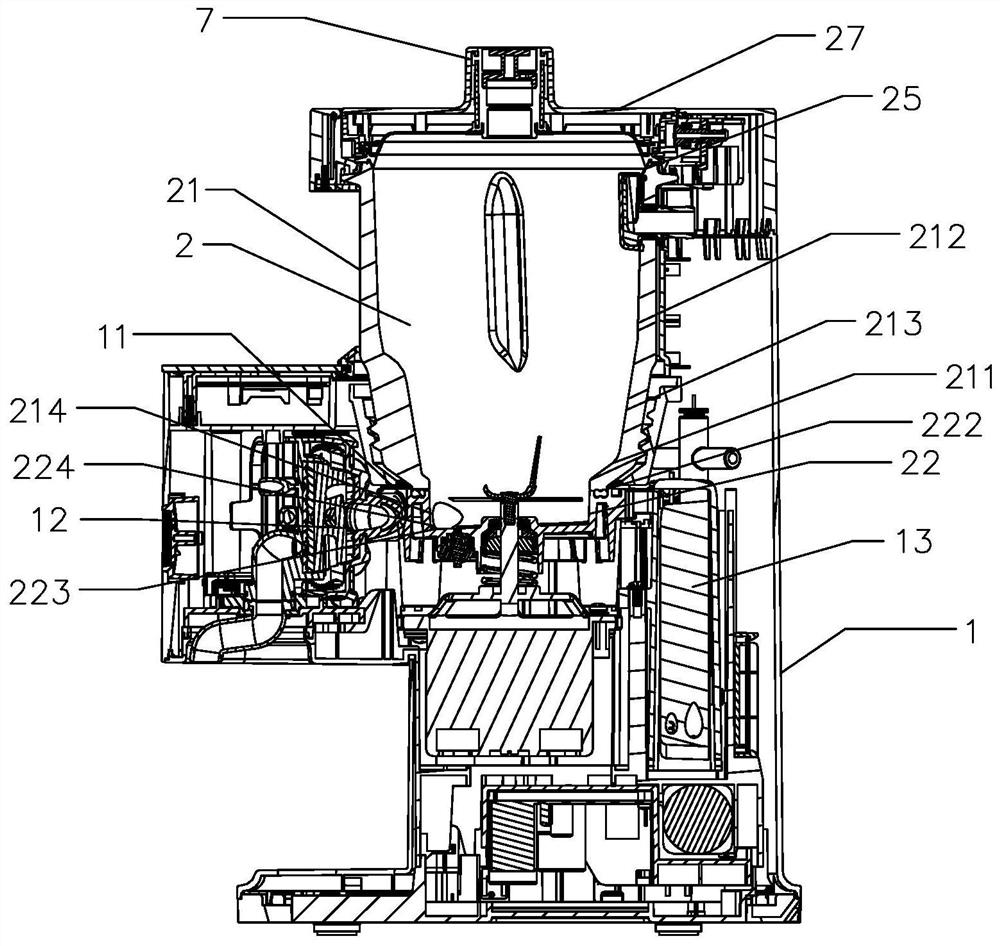

[0099] Such as image 3 with Figure 4 As shown, the body of the food processing machine is provided with a water tank 10, a control valve 12 and a steam generating device 13 are arranged in the body 1, a steam inlet 224 is arranged at the bottom of the metal plate 22, and the water supply in the water tank 10 The steam generating device 13, the steam generated by the steam generating device 13 is transmitted to the control valve 12 through the pipeline, and the control valve controls the steam to pass into the mixing cup 2 from the steam inlet. In this embodiment, the water inlet and the steam inlet 224 and the slurry discharge port 223 are the same, the control valve ...

Embodiment 3

[0113] The difference between this embodiment and Embodiment 1 is that the program of the food processing machine is also equipped with cold cleaning function, hot cleaning function, fast automatic cleaning function and one-key deep automatic cleaning function as in the embodiment, but due to the The capacity of the mixing cup of the above-mentioned food processor is small, so the amount and depth of the cleaning liquid injected are different, the process function of the automatic cleaning is the same, but the details of the steps of the cleaning process are different.

[0114] In this example, if Figure 5As shown, the bottom of the metal plate is provided with a heating device, the capacity V of the mixing cup of the food processor is 1200ml, the value of A / H is 0.12, and the distance A between the wing root of the crushing knife and the bottom of the mixing cup is 3 is 1.2A, the distance A between the upper end of the rib and the mouth of the cup 5 4mm, the length of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com