Double-arc sieving type light component separator with spraying function

A technology of light matter and separator, which is applied in the direction of separation of sediments by centrifugal force, grain treatment, solid waste removal, etc. It can solve problems such as difficult discharge and not optimal separation effect, and achieves convenient operation, convenient maintenance, and design advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

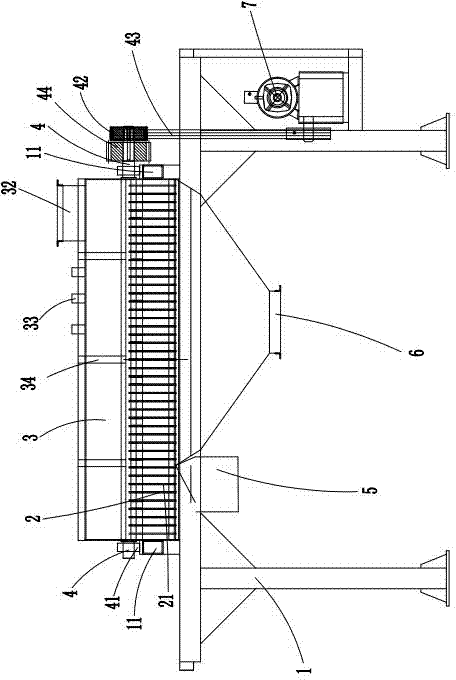

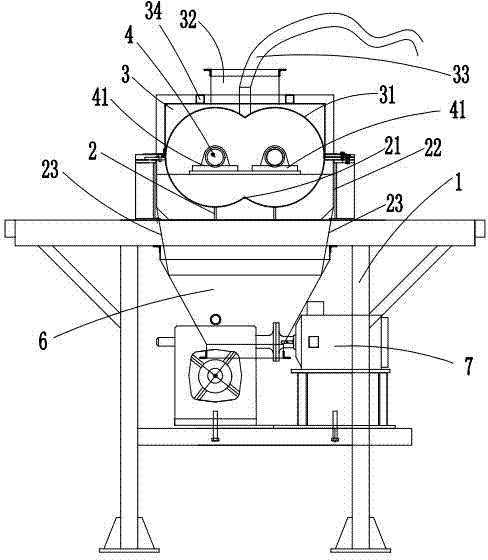

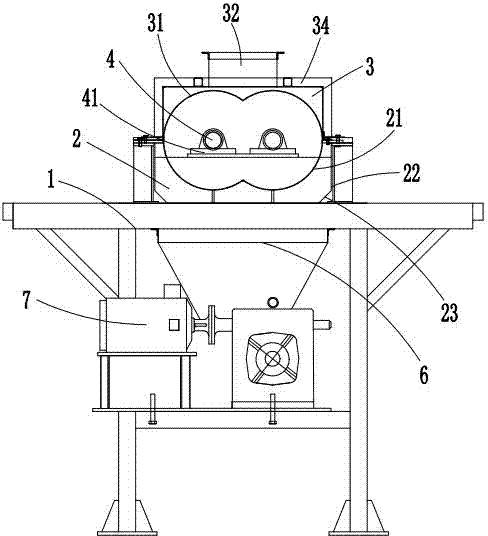

[0020] Such as Figure 1 to Figure 3 As shown, the icon numbers are explained as follows: base 1, seat support body 11, box base 2, double arc bottom sieve plate 21, diversion guard plate 22, material blocking plate 23, box cover body 3, double arc top sieve plate 31 , feed port 32, cleaning water access piece 33, upper cover shield 34, stirring shaft 4, shaft seat body 41, shaft pulley body 42, belt 43, gear 44, light material discharge body 5, separation discharge Body 6, drive motor 7.

[0021] In the embodiment of the present invention, a double-arc screening type light matter separator equipped with a spraying function, the separator includes a box base 2, and a box cover 3 is arranged above the box base 2; the middle cavity of the box base 2 is longitudinally arranged in parallel There are two stirring shafts 4; the inner wall of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com