Full-automatic brick cutting machine

A fully automatic, cutting machine technology, applied in ceramic forming machines, metal sawing equipment, sawing machine devices, etc., can solve the problems of difficulty in improving work efficiency, material waste, small block size, etc., to improve work efficiency and reduce usage. Cost, size easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

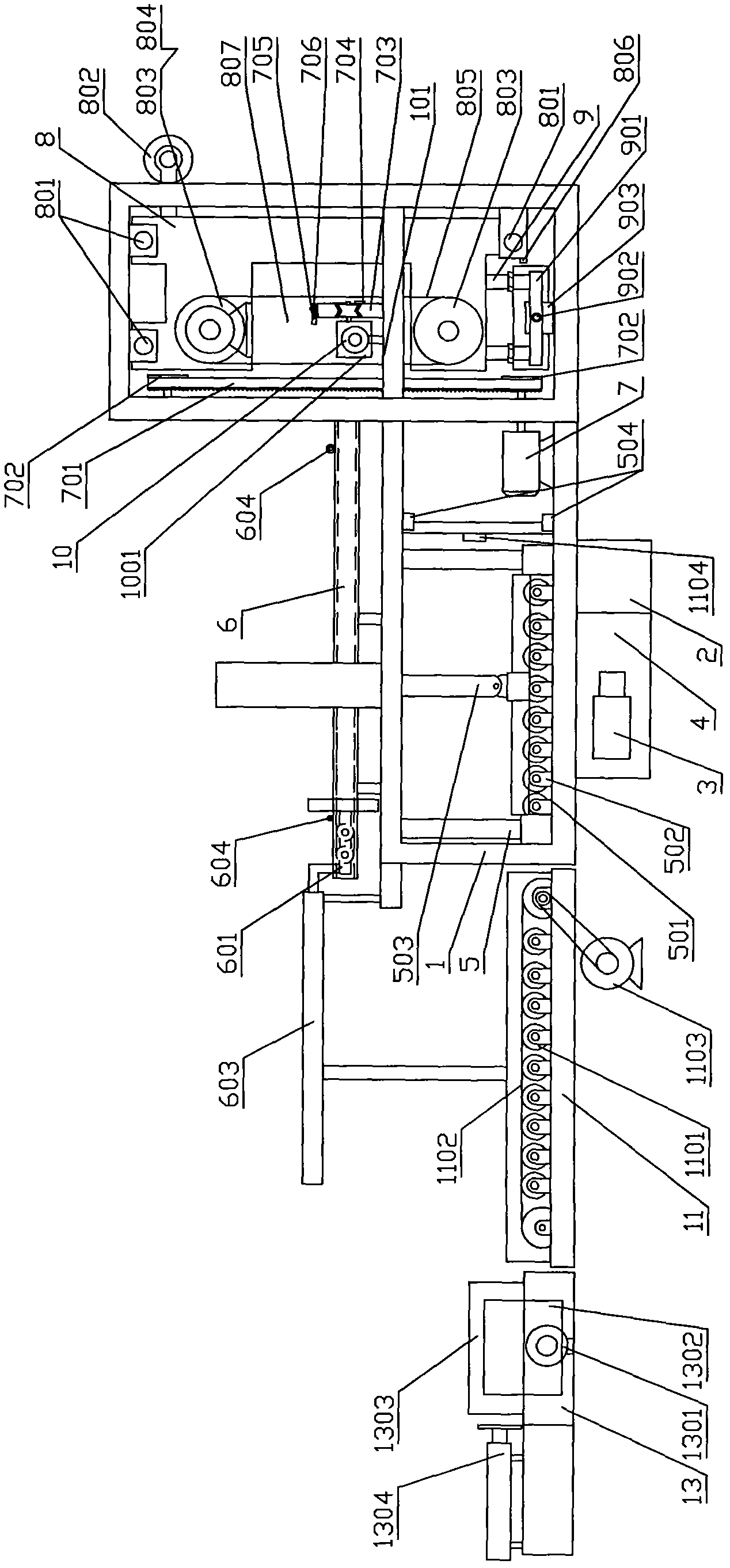

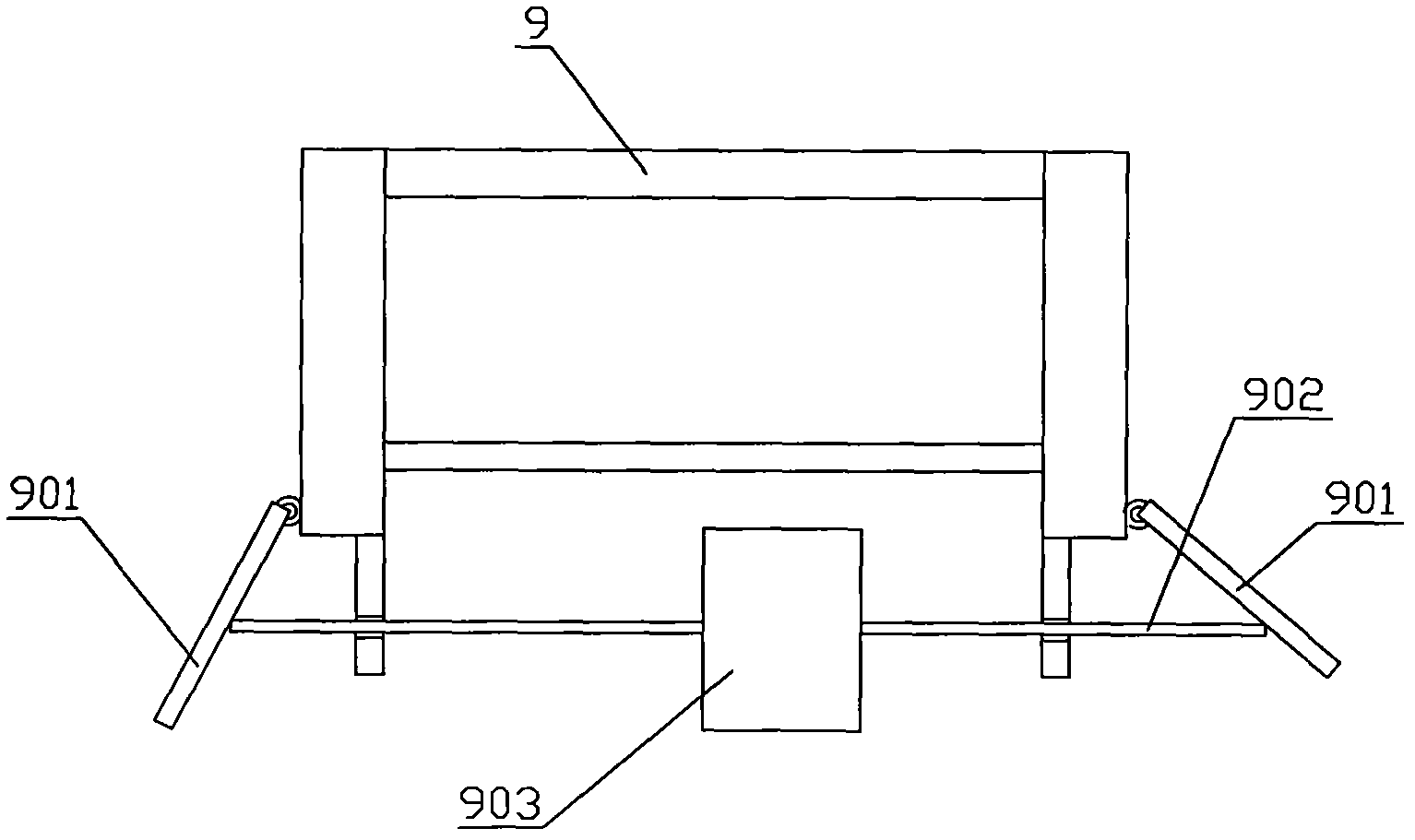

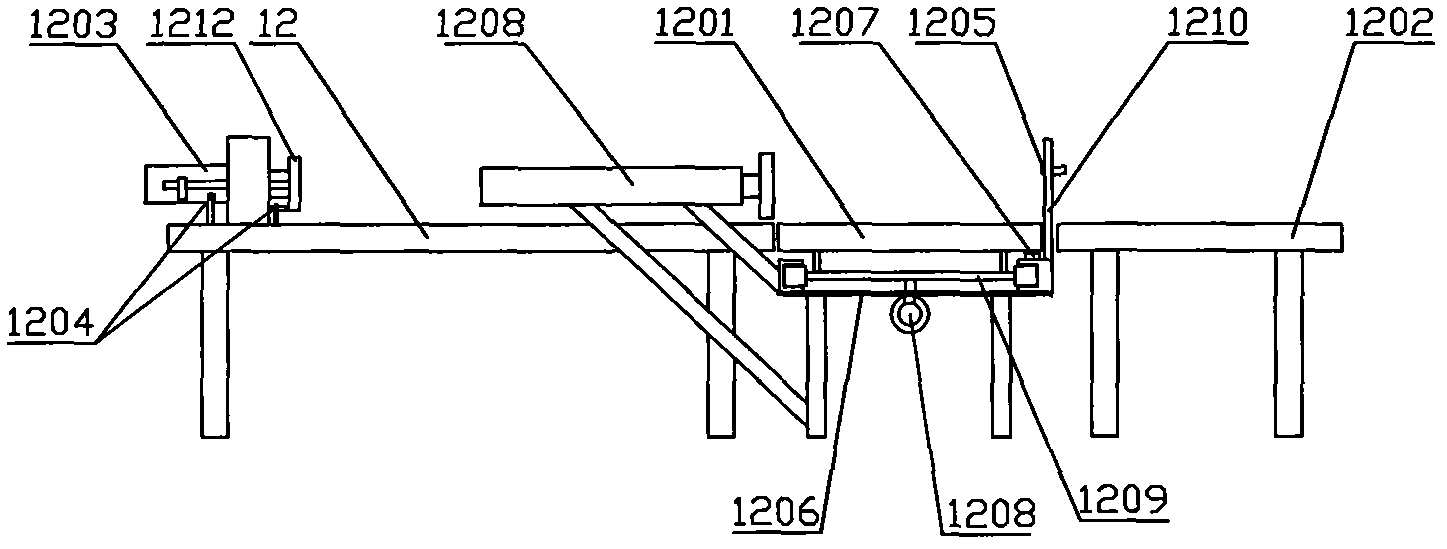

[0018] Depend on figure 1 , figure 2 , image 3 and Figure 4As shown, the automatic block cutting machine mainly includes a frame 1, an electric control cabinet 2, a hydraulic pump 3, an oil storage tank 4, a whole material mechanism, a material conveying mechanism, a material preparation mechanism, a material pushing mechanism, and a longitudinal sawing mechanism , horizontal sawing mechanism, unloading mechanism, material removal mechanism and material stacking mechanism, the electric control cabinet 2, hydraulic pump 3 and oil storage tank 4 are fixedly installed on the frame 1 respectively, and the electric control cabinet 2 and hydraulic pump 3 Electrically connected, the hydraulic pump 3 communicates with the oil storage tank 4 through the oil pipe, and the oil storage tank 4 provides an oil source for the hydraulic pump 3 to work. The material preparation mechanism mainly includes a guide column 5, a material preparation rack 501, a roller 502, a material preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com