Blow molding device for plastic boxes

A blow molding device and box body technology, applied in the field of plastic fuel tank manufacturing equipment, can solve the problems of clip plate damage, increased parts consumption, long production stop time, etc., and achieve the effect of shortening distance and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

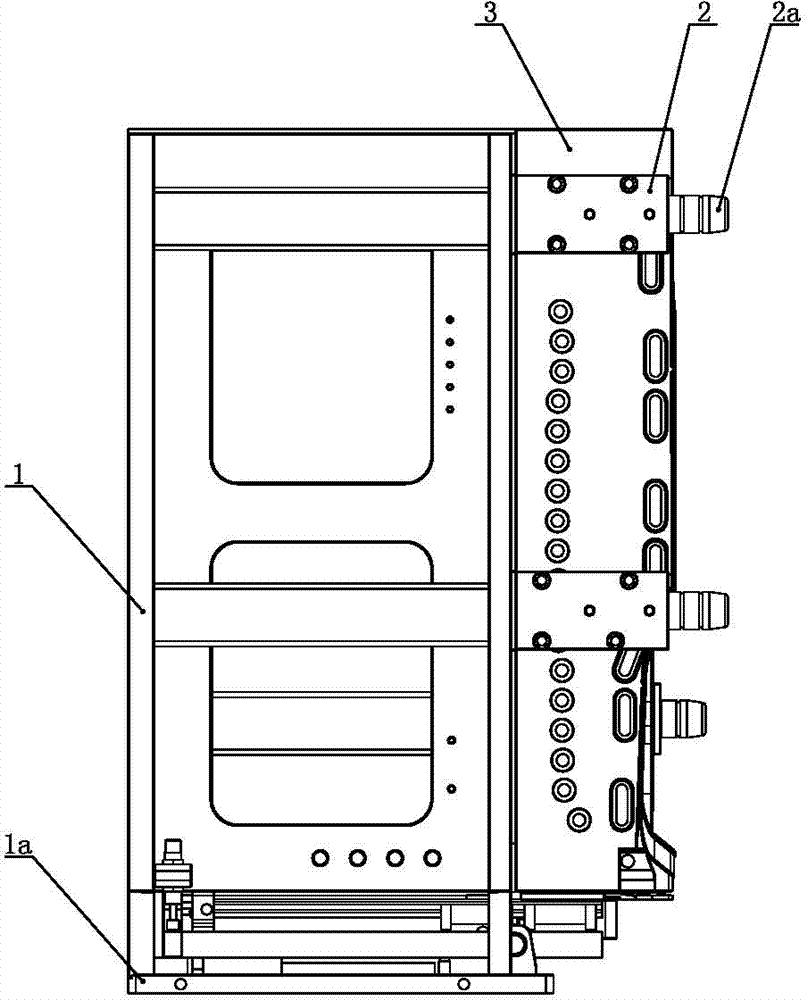

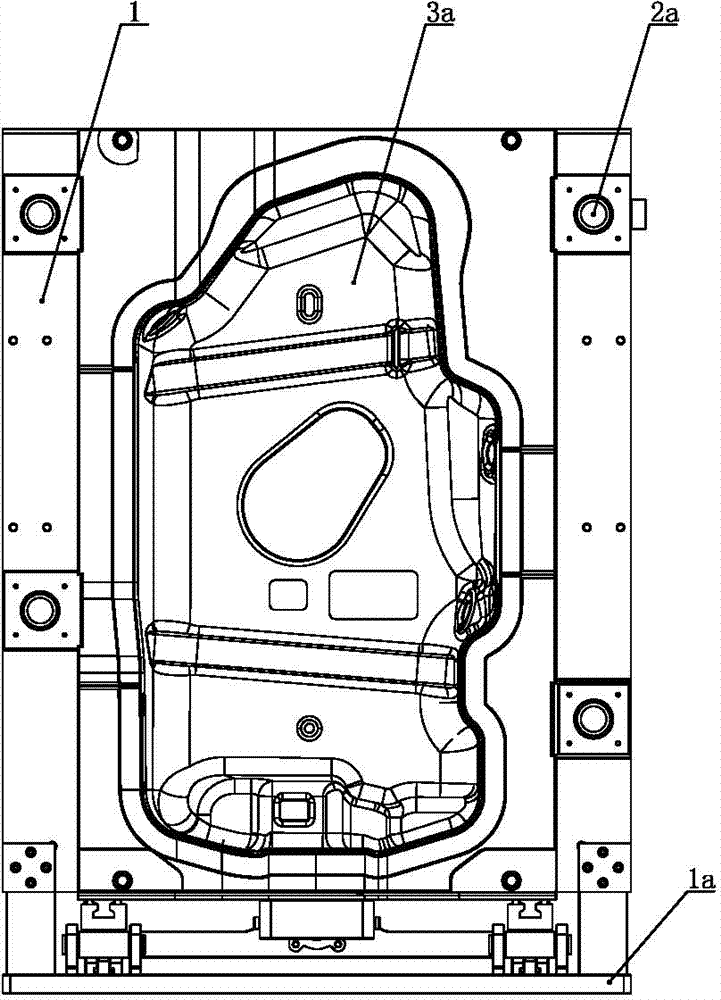

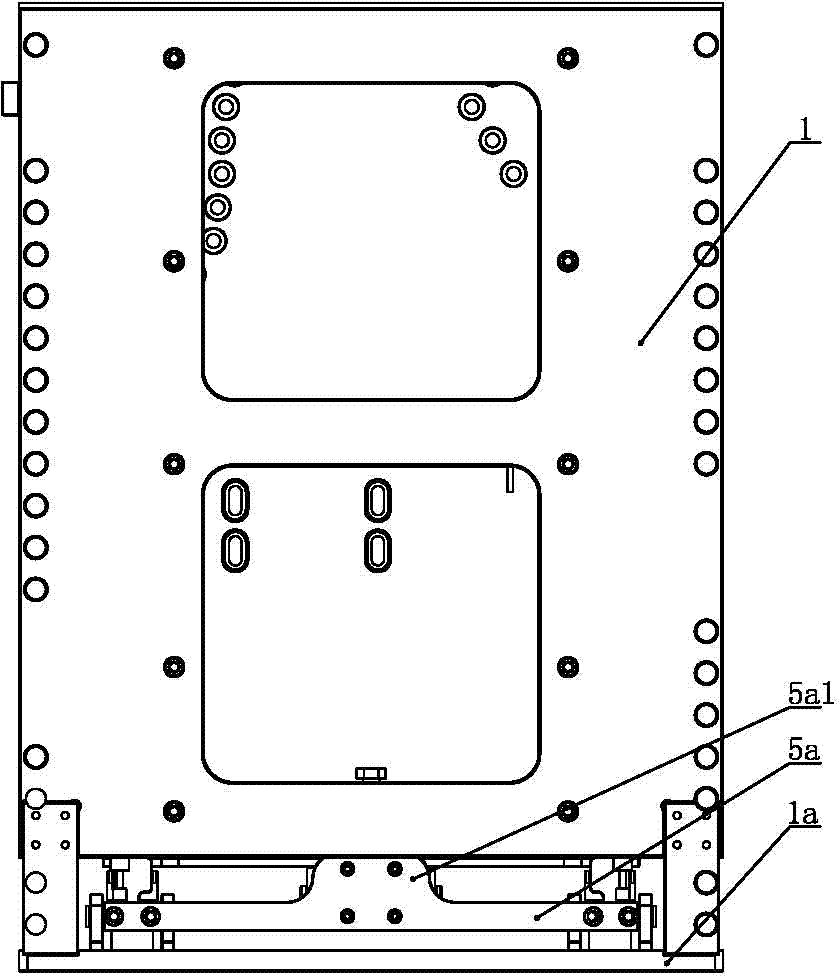

[0036] Such as Figure 1 to Figure 6 As shown, the blow molding device of the plastic box of the present invention comprises left and right mold bases which are respectively located at the left and right sides of the parison and which can move towards each other. The left and right half molds are respectively installed on the opposite end faces of the frame, and the opposite end faces of the left and right half molds are respectively provided with a cavity 3a having the same shape and size as the left and right halves of the fuel tank. There is a clamping device. Because the left and right mold bases are symmetrical, for the sake of simplicity, only the left mold base 1 and half mold 3 are shown in the figure. The mold base 1 is respectively provided with a mold positioning block 2 and a mold positioning pin 2a. When the mold positioning pin 2a is inserted into the pin hole of the mold positioning block 2, the left and right half molds are aligned and enter the mold closing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com