Wheel house panel mounting structure

A technology for installing structures and cover plates, which is applied to superstructures, subassemblies of superstructures, transportation and packaging, etc. It can solve problems such as insufficient operating space, prolonged assembly time, and difficulties in installation and disassembly, so as to improve assembly efficiency and installation And disassembly is simple and convenient, saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

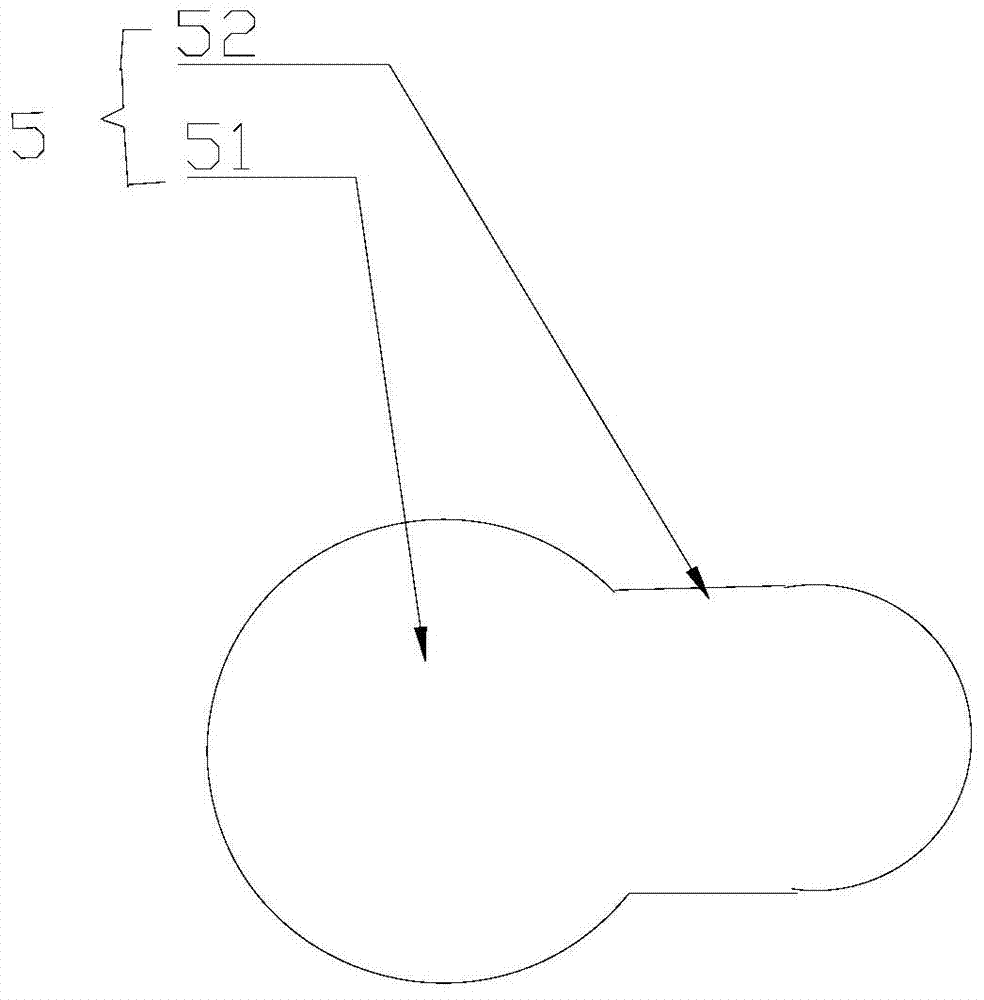

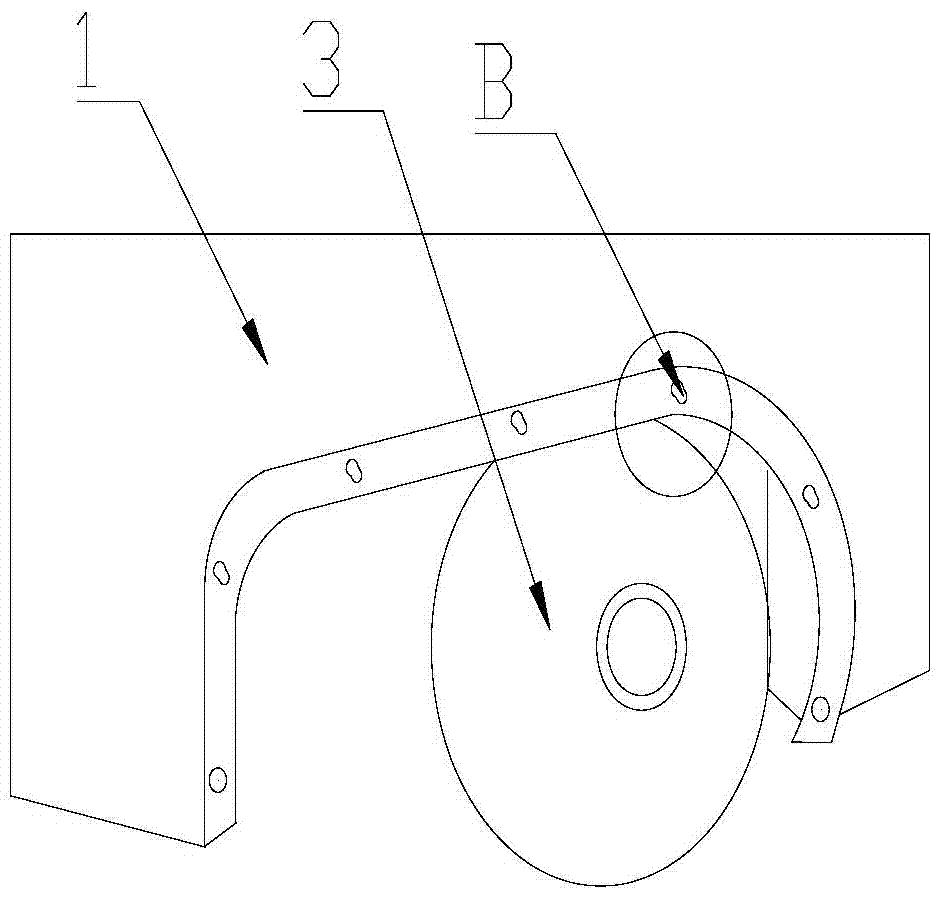

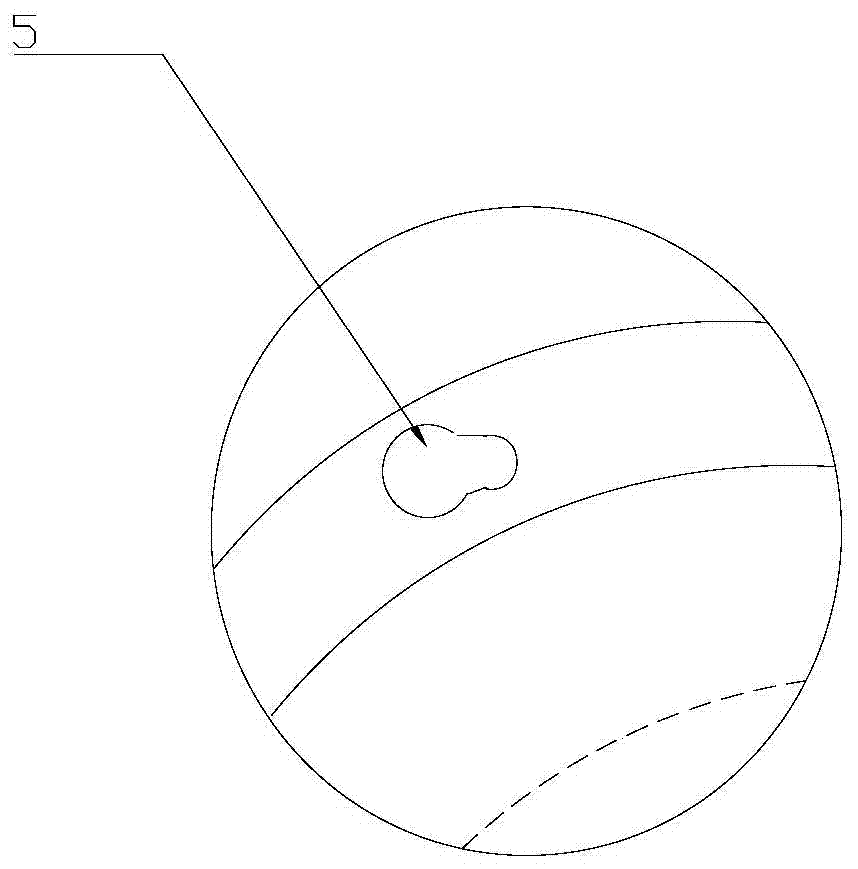

[0028] Such as Figure 1 to Figure 7 As shown, the installation structure of the wheel cover plate includes the wheel cover plate 2. The wheel cover plate 2 is installed on the wheel wing plate 1 of the car shell to protect the wheels 3. The wheel cover plate 2 is provided with five mounting buckle assemblies 6 and the mounting hole 7, the mounting buckle assembly 6 is composed of a mounting cap 62 and a mounting buckle 61, the mounting buckle 61 is connected in turn by the first cylinder 611, the second cylinder 612 and the third cylinder 613 from thick to thin, and the wheel wing The installation buckle fitting hole 5 on the board 1 includes a fitting portion 51 and a locking portion 52 connected thereto. The fitting portion 51 and the locking portion 52 are circular hole structures, and the diameter of the fitting hole 51 is larger than that of the locking portion 52 , the third cylinder 613 passes through the mounting hole 7 from one side of the wheel house plate 2, the mo...

Embodiment 2

[0033] Such as Figure 1 to Figure 3 , Figure 8 and Figure 9 As shown, this embodiment is roughly the same as Embodiment 1, and the difference is that in Embodiment 1, the mounting buckle assembly 6 is composed of a mounting cap 62 and a mounting buckle 61, and the mounting buckle 61 is composed of a first cylinder 611, a second The cylinder 612 and the third cylinder 613 are connected sequentially from thick to thin, and the mounting buckle assembly can be a plastic mounting buckle assembly. In this embodiment, the mounting buckle assembly 6 is two-layer stepped, made of metal, and connected to the wheel house plate 2 by welding.

[0034] In the present invention, the mounting buckle fitting holes connected with the mounting buckle assembly and the matching portion and the locking portion are adopted. When installing, only the mounting buckle assembly on the rear wheel cover plate and the mounting buckle fitting hole of the wheel wing plate need to be aligned. Then slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com