A kind of separation method and separation system of trace benzene in vinyl acetate

A vinyl acetate and separation method technology, applied in the field of separation method and separation system of trace benzene in vinyl acetate, can solve the problems of small polarity difference, high technical difficulty, inapplicability, etc., achieve low raw material loss, The effect of simple process flow and simple structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

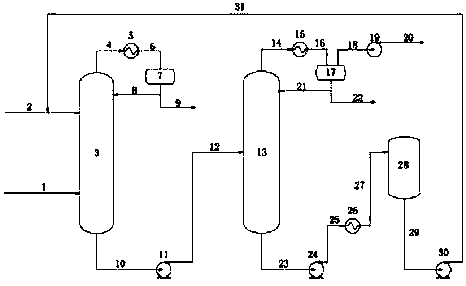

[0032] A method for separating trace amounts of benzene in vinyl acetate, the method adopts the structure as attached figure 1 The conventional production device shown is carried out, and the purity of its raw material vinyl acetate is 99.93wt%, and benzene content is 1.91PPm, and extractant adopts C 12 ~C 14The mixed alkanes, and the mass ratio of extractant and raw material vinyl acetate is 0.6, and the polymerization inhibitor p-benzoquinone that adds content to be 5PPm in raw material vinyl acetate; This raw material vinyl acetate enters through raw material vinyl acetate inlet pipe 1 The lower part of the extractive distillation tower 3, the extractant in the extractant storage tank 28 is sent to the upper part of the extractive distillation tower 3 through the solvent pump 30, the raw material vinyl acetate and the extractant are countercurrently contacted for mass transfer, the heating temperature in the extractive distillation tower 3 at 92°C, normal pressure, and a r...

Embodiment 2-7

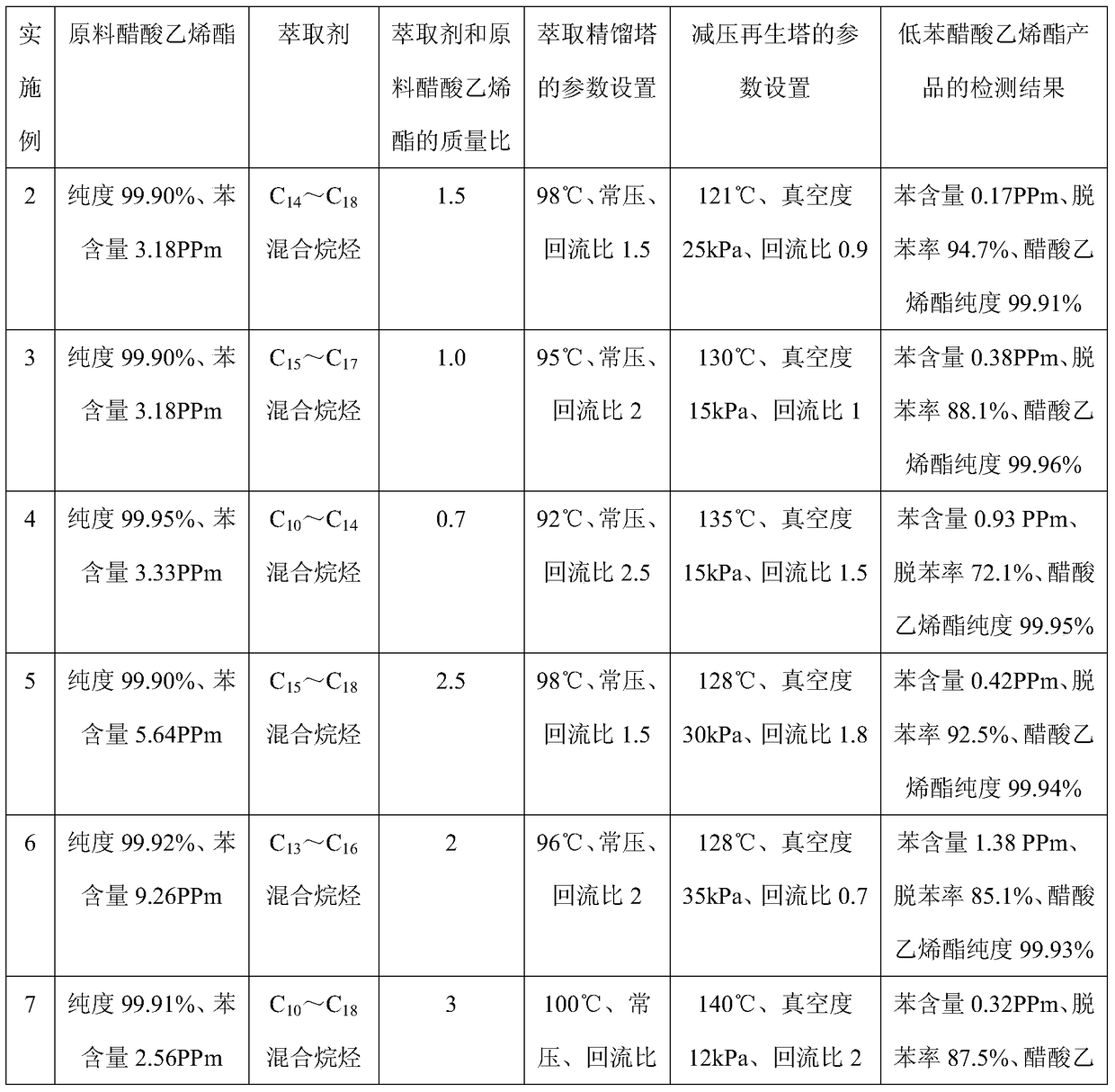

[0041] Embodiment 2-7 is carried out by following materials, technique and parameter, and all the other settings are identical with embodiment 1:

[0042]

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com